A pvc synthetic resin tile

A technology of synthetic resin and dibasic lead stearate, which is applied in the field of PVC synthetic resin tiles, can solve the problems of unqualified products, waste of time, waste of materials, etc., and achieve the effect of clear proportioning, light material quality and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

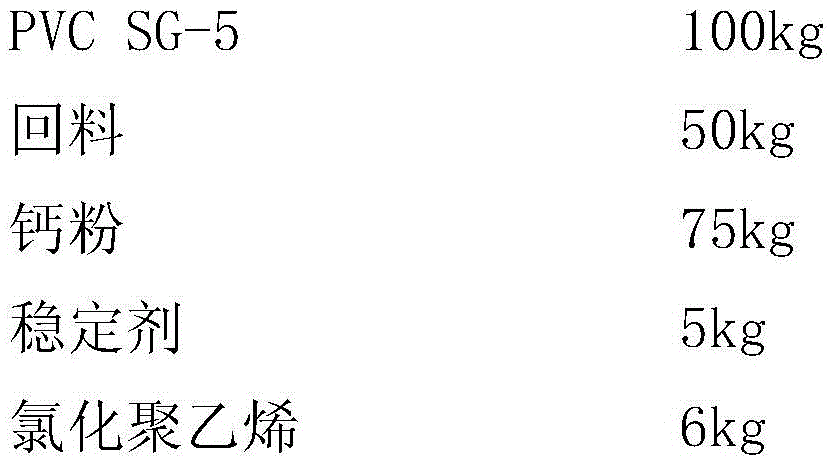

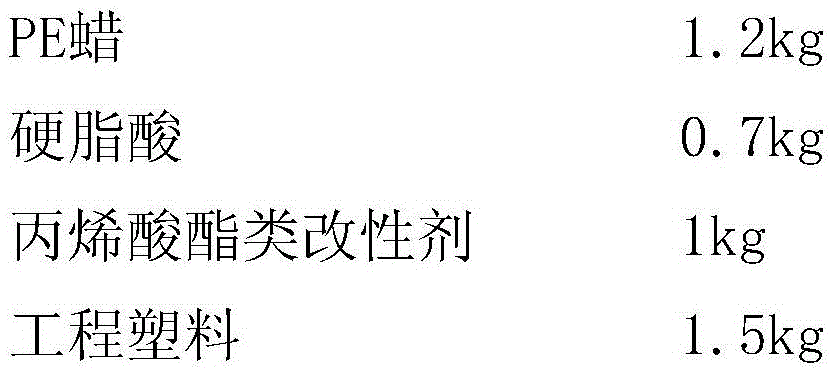

[0021] A PVC synthetic resin tile, characterized in that it comprises the following components,

[0022]

[0023]

[0024] The recycled material is one or more of nylon and low-density polyethylene;

[0025] The stabilizer is one of a dibasic lead phosphite stabilizer, a dibasic lead stearate stabilizer and a tribasic lead sulfate stabilizer;

[0026] The engineering plastic is a graft copolymer of acrylic rubber body, acrylonitrile and styrene;

[0027] The processing method of the PVC synthetic resin tile includes the following steps:

[0028] ①Put the PVCSG-5 and recycled materials into a crusher and crush them into powder;

[0029] ②Then put PVCSG-5 powder, calcium powder, stabilizer, recycled powder, stearic acid, chlorinated polyethylene, acrylate modifier, and PE wax into the mixer in order and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com