Preparation method of large-scale high-aluminum-content iron-chromium-aluminum alloy sheet material

An iron-chromium-aluminum alloy and sheet material technology, applied in metal material coating process, ion implantation plating, coating, etc. The effect of good oxidation performance, high aluminum content and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

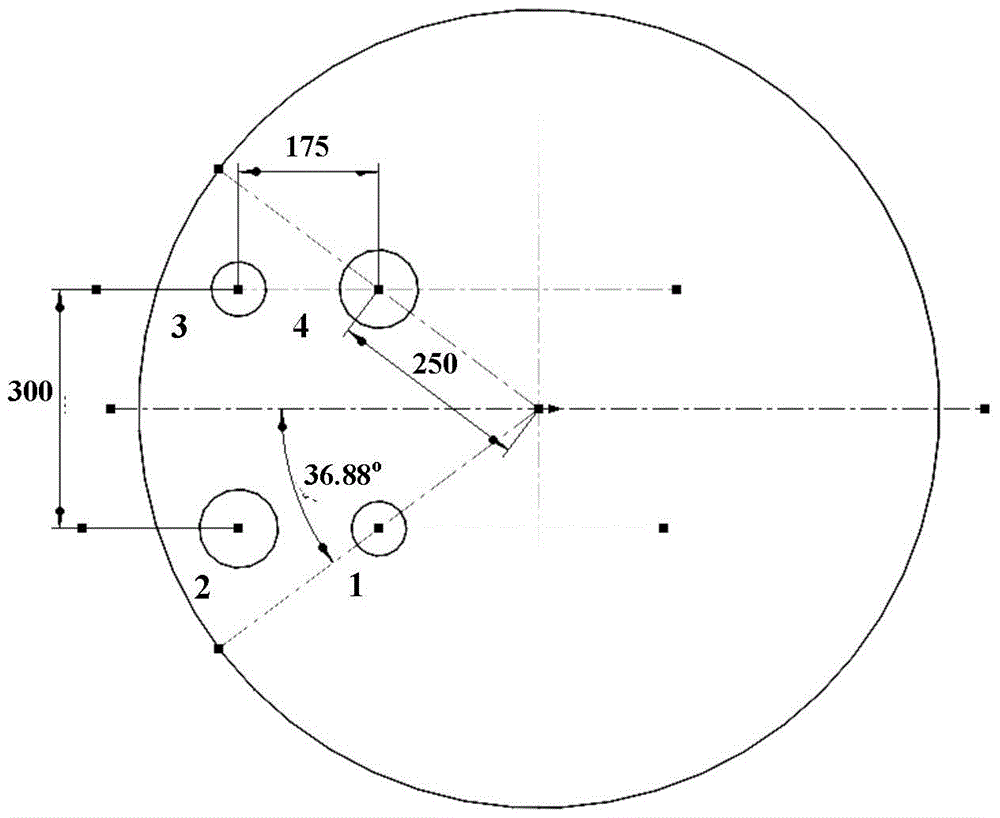

[0019] Specific Embodiment 1: In this embodiment, the large-scale iron-chromium-aluminum alloy thin plate material with high aluminum content has a thickness of 0.1-0.3mm and a diameter of 1000mm, and the composition of the thin plate is 15.0%-20.0%Cr, 10.0%-15.0% by weight Composition of Al and a balance amount of Fe.

specific Embodiment approach 2

[0020] Specific embodiment 2: The preparation method of the large-size high-aluminum-content iron-chromium-aluminum alloy sheet material described in specific embodiment 1 is carried out according to the following steps:

[0021] 1. Put the aluminum-containing ingot into a water-cooled copper crucible, place 35 grams of tungsten and 10-15 grams of calcium fluoride on the surface of the aluminum-containing ingot, install the superalloy substrate on the substrate frame, and wipe the surface with absolute ethanol , evacuated to 1×10 -3 Pa-5×10 -3 Pa, then heat the superalloy substrate to 660-1000°C and keep it warm;

[0022] 2. Cover the superalloy substrate treated in step 1 with a baffle, increase the electron beam current to 1.6-3A, and stabilize it for 1-20 minutes, open the baffle, and deposit 1-10 μm thick on the superalloy substrate CaF 2 ;

[0023] 3. Use 1.6-3A electron beam current to evaporate the aluminum-containing ingot for 10-60min, and the vacuum degree is 1×1...

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, the vacuum is pumped to 3×10 -3 Pa. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com