Method and device for preparing nano-composite yarns

A technology for nanocomposite, device preparation, applied in yarn, textile and papermaking, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

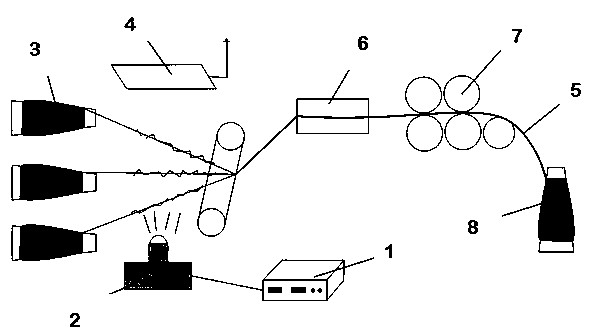

[0022] Put a certain concentration of spinning solution in the liquid storage tank of the air bubble electrospinning equipment 2, apply a suitable voltage through the high-voltage power supply 1, adjust the distance between the receiving plate, use nylon fiber filament as the core material, and use 2 output devices to output Then compound, passing between the liquid storage tank and the receiving plate, the spinning solution is stretched under the action of the electric field to form nanofibers, which are deposited on the nylon fiber filaments drawn forward at a speed of 0.1m / min, and the surface The core material deposited with nanofibers is coagulated through a coagulation bath, and then output after being processed by five pressing rollers to obtain composite nylon long yarns coated with nanofibers on the surface.

[0023] Nylon fiber has high strength, strong elongation, excellent elasticity, and good wear resistance, but it is easy to absorb water, and has poor heat resist...

Embodiment 2

[0025] Put a certain concentration of spinning solution in the liquid storage tank of the air bubble electrospinning equipment 2, apply a suitable voltage through the high-voltage power supply 1, adjust the distance between the receiving plate, use silk and polyurethane fiber filament as the core material, and use 8 output Device compounding, 4 of which are used for silk output, and the other 4 are used for polyurethane fiber filament output, passing between the bubble reservoir and the receiving plate, the spinning solution is stretched under the action of the electric field to form nanofibers, Deposited on silk fibers pulled forward at a speed of 2m / min, the core material with nanofibers deposited on the surface was solidified through a coagulation bath, and then output after being processed by 15 pressing rollers to obtain a composite long yarn coated with nanofibers on the surface.

[0026] Silk fiber has good hygroscopicity, strength and elongation are relatively good amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com