Ultra-high molecular weight polyethylene composite formwork and manufacturing method and device thereof

An ultra-high molecular weight, polyethylene board technology, applied in the fields of formwork/template components, chemical instruments and methods, and on-site preparation of building components, can solve the inevitable incompatibility interface between foamed materials and non-foamed materials , The reinforcement effect of chopped glass fiber is far less than the reinforcement effect of fiber mesh, and the improvement of template strength is not enough, so as to achieve the effect of high resistance to environmental stress cracking, high compressive strength, good bonding fastness, and easy demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

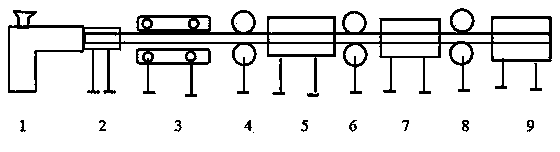

[0051] The ultra-high molecular weight polyethylene raw material is extruded through the extruder, and the temperature of each zone of the first extruder is set at 100°C, 160°C, 200°C, 230°C, the die temperature is set at 230°C, and the speed of the main engine is 400r / min;

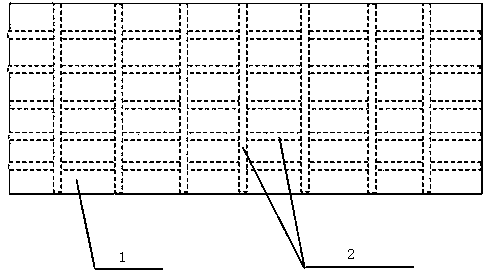

[0052] The raw materials are plasticized and extruded into the plate mold to obtain an ultra-high molecular weight polyethylene plate with a wall thickness of 3 mm. The ultra-high molecular weight polyethylene plate is cooled and shaped, and cut to length to obtain a plate with a length of 180 mm and a width of 90 mm. The cut plate enters the composite mold through the guide roller. The pressure of the composite mold is 14MPa, the temperature is 230°C, and the composite time is 30min. The glass fiber composite tape is interlaced between two layers of ultra-high molecular weight polyethylene sheets, and the stagger angle is 90°;

[0053] At this time, the inner and outer layers of polyethylene and the polye...

Embodiment 2

[0055] The ultra-high molecular weight polyethylene raw material is extruded through the extruder. The temperature of each zone of the first extruder is set at 100°C, 160°C, 200°C, and 230°C, the die temperature is set at 230°C, and the speed of the main engine is 300r / min;

[0056] The raw materials are plasticized and extruded into the plate mold to obtain an ultra-high molecular weight polyethylene plate with a wall thickness of 4mm. The ultra-high molecular weight polyethylene plate is cooled and shaped, and cut to length to obtain a plate with a length of 200mm and a width of 90mm. The cut plate enters the composite mold through the guide roller. The pressure of the composite mold is 16MPa, the temperature is 230°C, and the composite time is 30min. The glass fiber composite tape is interlaced between two layers of ultra-high molecular weight polyethylene sheets, and the stagger angle is 90°.

[0057] At this time, the inner and outer layers of polyethylene and the polyethy...

Embodiment 3

[0059] The ultra-high molecular weight polyethylene raw material is extruded through the extruder, and the temperature of each zone of the first extruder is set at 100°C, 160°C, 200°C, 230°C, the die temperature is set at 230°C, and the speed of the main engine is 200r / min;

[0060] The raw materials are plasticized and extruded into the plate mold to obtain an ultra-high molecular weight polyethylene plate with a wall thickness of 5 mm. The ultra-high molecular weight polyethylene plate is cooled and shaped, and cut to length to obtain a plate with a length of 180 mm and a width of 100 mm. The cut plate enters the composite mold through the guide roller. The pressure of the composite mold is 16MPa, the temperature is 230°C, and the composite time is 30min. The glass fiber composite tape is interlaced between two layers of ultra-high molecular weight polyethylene sheets, and the stagger angle is 90°.

[0061] At this time, the inner and outer layers of polyethylene and the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com