Wavelength division multiplexing optical fiber hydrogen sensing system capable of achieving multi-point monitoring

A wavelength division multiplexing, multi-point monitoring technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of complexity, cost and volume increase, and achieve the effect of saving the number of equipment, reducing restrictions, and being easy to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

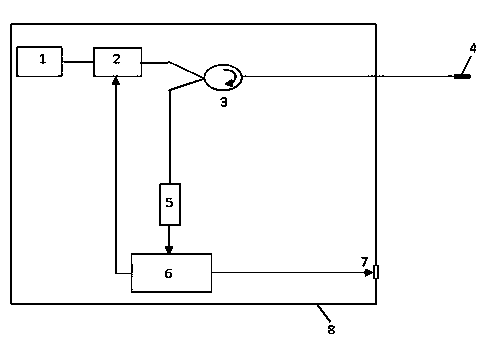

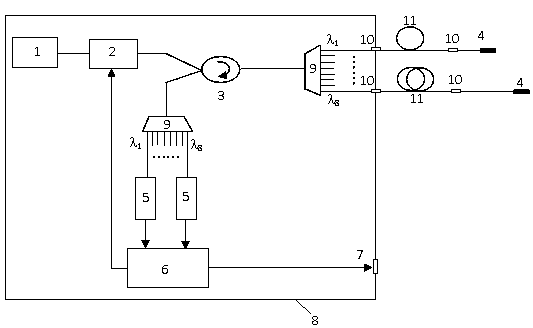

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0028] Most of the fiber optic gas sensing systems use the principle of gas spectral absorption, that is, each gas has its own absorption spectrum. When the emission wavelength of mature) coincides with the characteristic absorption peak wavelength of the gas, resonance absorption will occur, and its absorption intensity is related to the concentration of the gas. By measuring the absorption intensity of light, the gas and its concentration can be measured. Based on the principle of gas spectral absorption, a variety of fiber optic gas sensing systems have been developed, and the technology is mature. There are commercial products and practical applications, which can detect carbon dioxide CO 2 , methane CH 4 , water vapor H 2 O, nitrogen dioxide NO 2 , carbon monoxide CO, acetylene C 2 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com