Power generation device provided with hydrogen storage bottle made of copper-based alloy composite material

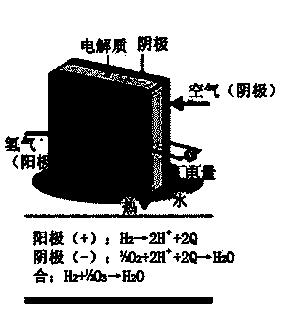

A technology for power generation devices and hydrogen storage devices, which is applied in the directions of fuel cells, fuel cell additives, circuits, etc., can solve the problems of potential safety hazards and low storage system efficiency, and achieve the goal of reducing costs, solving environmental pollution, and having broad development prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

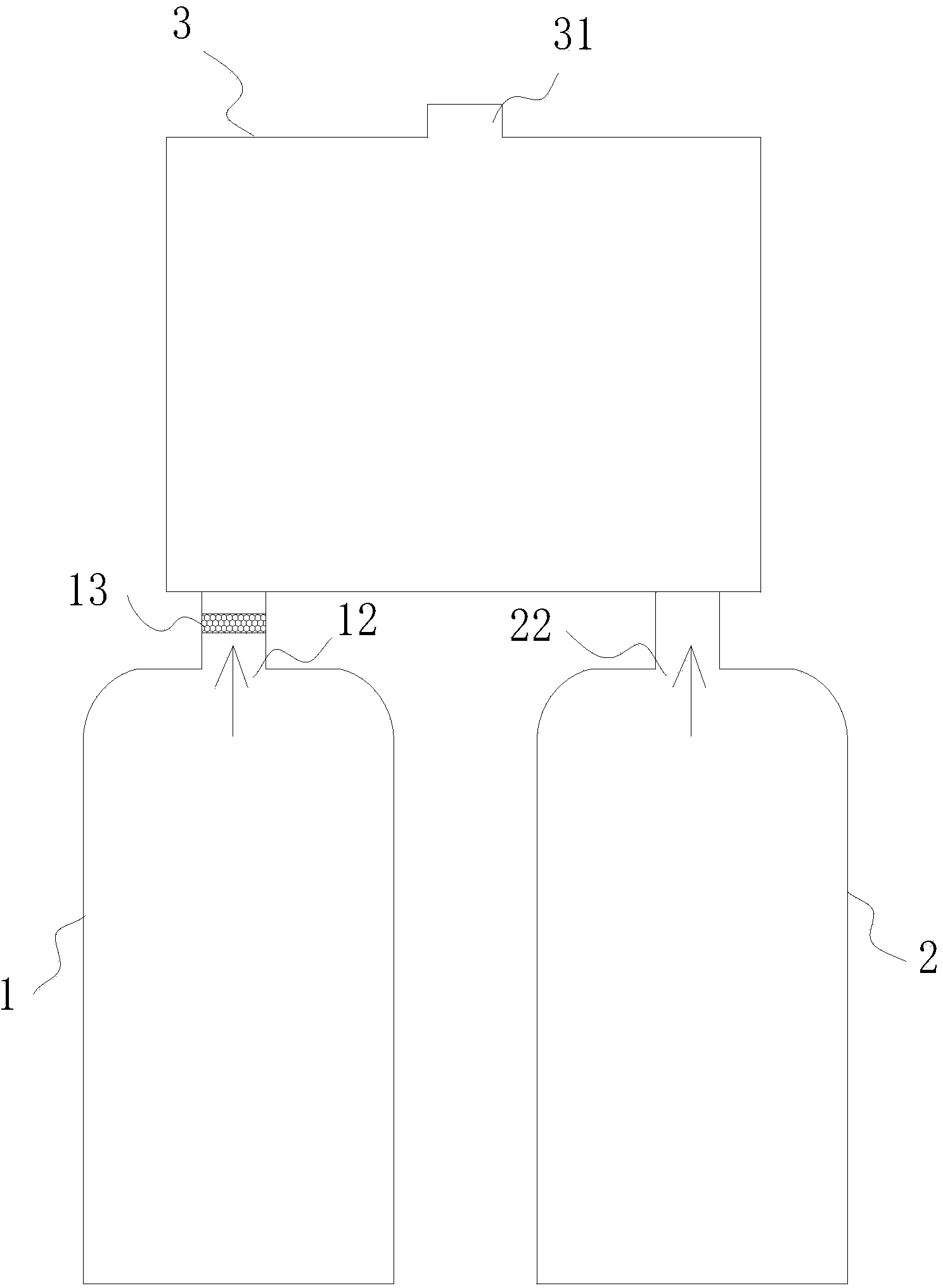

[0032] A copper-based alloy containing the following mass % chemical elements is used to prepare the hydrogen storage bottle liner of the solid-state hydrogen storage device of the present invention, aluminum 12, beryllium 0.8, boron 0.2, chromium 0.2, titanium 0.08, cerium 0.1 and the balance of copper. The wall thickness of the inner tank of the hydrogen storage bottle is 2 mm. The carbon fiber reinforced material is attached to the inner tank and cured to form the shell of the hydrogen storage bottle, and the thickness of the carbon fiber reinforced layer is 0.5mm.

Embodiment 2

[0034] The operation of Example 1 was repeated, except that the mass % of the chemical elements was modified to 20 aluminum, 0.5 beryllium, 0.4 boron, 0.1 chromium, 0.05 titanium, 0.05 lanthanum and the balance of copper. The wall thickness of the inner tank of the hydrogen storage bottle is 5mm. The thickness of the carbon fiber reinforced layer is 2.5mm.

Embodiment 3

[0036] The operation of Example 1 was repeated, except that the mass % of certain chemical elements was modified to 10 for aluminum, 1.5 for beryllium, and 0.2 for titanium. The wall thickness of the inner tank of the hydrogen storage bottle is modified to 6mm. The thickness of the carbon fiber reinforced layer is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com