Gold ore roasting tail gas recovery technology

A technology of tail gas recovery and roasting, applied in non-metallic elements, inorganic chemistry, sulfur compounds, etc., can solve the problems of loss, waste of raw materials and costs, and achieve the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

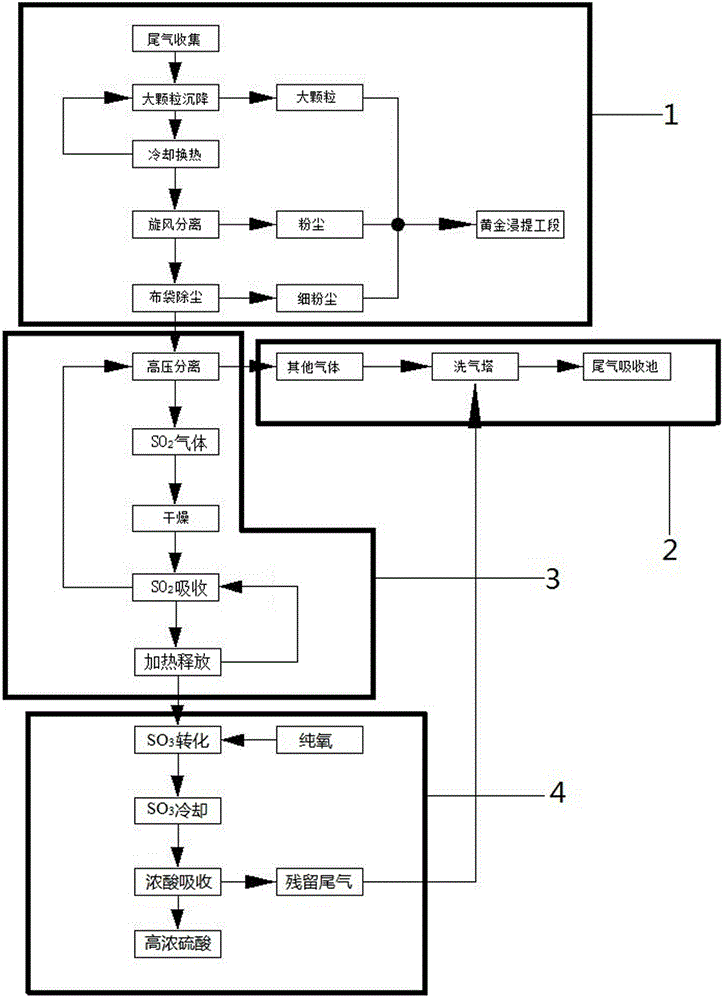

[0016] Such as figure 1 Shown is a gold mine roasting tail gas recovery process, including flue gas dust removal section, tail gas purification section, SO purification section 2 Section, SO 3 Conversion and absorption section, flue gas dedusting section and SO purification 2 Section connection, purification of SO 2 Section connection SO 3 Conversion and absorption section, purification of SO 2 Section and SO 3 The tail gas produced in the conversion and absorption section is sent to the tail gas purification section, and the gas produced in the flue gas dust removal section is sent to the high-pressure separation chamber to separate SO 2 Gas, separated SO 2 The gas is sent to a drying oven for drying, and a desiccant is installed in the drying oven, and the dried SO 2 The gas is sent to the absorption box filled with diethyl ethyl phosphate absorption liquid, and the unabsorbed SO 2 The gas is sent to the high-pressure separation chamber for secondary separation treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com