an isotope 13 separation method of c

A separation method and isotope technology, applied in the field of stable isotope 13C separation and preparation, can solve the problems of high cost, low possibility and low cost of cryogenic rectification, and achieve low operating cost, flexible scale and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

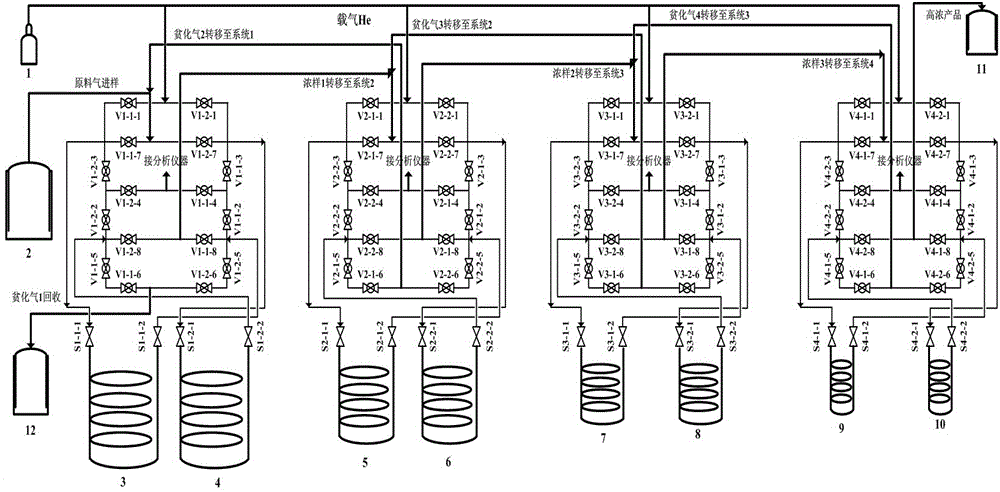

[0070] an isotope 13 C separation methods such as figure 1 As shown, the chromatographic column I3 of the primary separation system, the chromatographic column II4 of the primary separation system, the chromatographic column I5 of the secondary separation system, the chromatographic column II6 of the secondary separation system, the chromatographic column I7 of the third stage separation system, and the The chromatographic column II8 of the system, the chromatographic column I9 of the four-stage separation system, and the chromatographic column II10 of the four-stage separation system are a four-stage cascading process. The length of each single chromatographic column is 36, 32, 24, and 16m respectively , the outer diameters of the columns are 1.5, 1.0, 0.5, and 0.375 inches, and the columns are filled with 5A molecular sieves. The annual production capacity is 10m 3 Abundance 99% 13 CO gas, the specific parameters are shown in Table 1.

[0071] Table 1 Isotopes 13 Separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com