A method for preparing lignin-based cationic organic flocculant from papermaking sludge

An organic flocculant, papermaking sludge technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor flocculation effect, etc., and achieve the effect of less equipment requirements, easy availability of raw materials, and high flocculation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

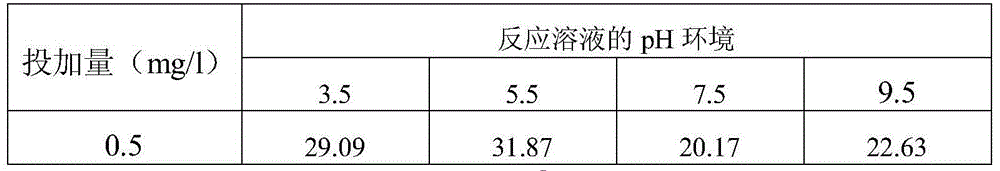

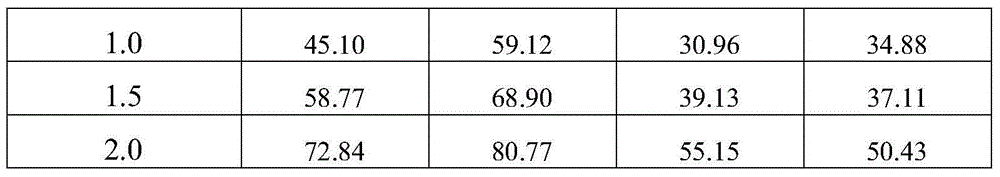

[0032] Example 1. Preparation of flocculants (L-N) with different pH

[0033] Weigh 2.0g of papermaking sludge, add 60ml of deionized water and 1mol / L NaOH solution, stir to stabilize the pH at 11.5, centrifuge at 8000rpm for 15min, take the supernatant, adjust the pH to 3.5, 5.5, 7.5, 9.5, Put the reactor in a constant temperature water bath at 70°C, stir for 5 minutes, add 8ml of N,N-dimethylformamide and 8ml of epichlorohydrin into the reactor, and stir for 1 hour at a speed of 200rpm. The reaction is The first stage reaction; then slowly add 3ml of ethylenediamine dropwise, and then react for 1h, this reaction is the second stage reaction; finally drop 10ml triethylamine, react for 2h, this reaction is the third stage reaction; Cool the product to room temperature, add 200ml of acetone to precipitate the product, pressurize 0.015MPa to vacuum filter, and vacuum-dry the filter residue at 60°C to obtain four products with different reaction pHs. The products prepared with p...

Embodiment 2

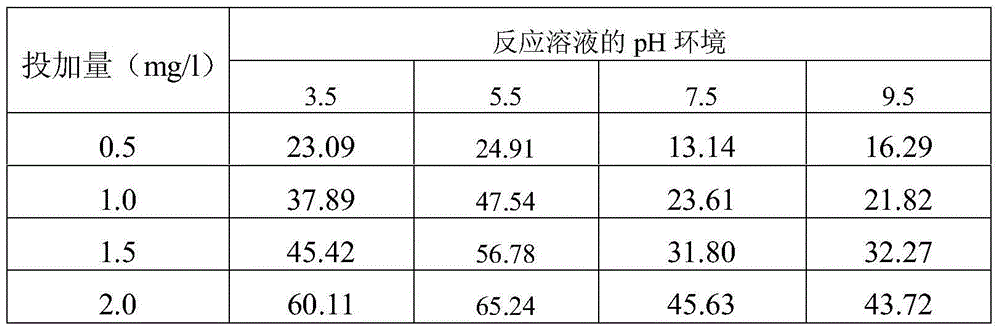

[0034] Example 2. Preparation of flocculants (L-N) with different additions of N,N-dimethylformamide and epichlorohydrin

[0035] The same as described in Example 1, the difference is that the pH of the supernatant is adjusted to 5.5, and the addition amounts of N,N-dimethylformamide and epichlorohydrin are respectively 6ml, 8ml, 10ml, and 12ml, to obtain The flocculant products with different addition amounts of N,N-dimethylformamide and epichlorohydrin, the addition amounts of N,N-dimethylformamide and epichlorohydrin are 6ml, 8ml, 10ml, and 12ml respectively. The products are respectively denoted as 1#, 2#, 3#, 4# flocculant of embodiment 2.

Embodiment 3

[0036] Example 3. Preparation of flocculants (L-N) with different reaction times in the first stage

[0037] The same as described in Example 2, the difference is that the addition amount of N,N-dimethylformamide and epichlorohydrin is 8ml, that is, the flocculant products with different reaction times in the first stage are obtained. The reaction time is 30min, 45min, 60min, 75min respectively, and the obtained products are respectively recorded as 1#, 2#, 3#, 4# flocculants of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com