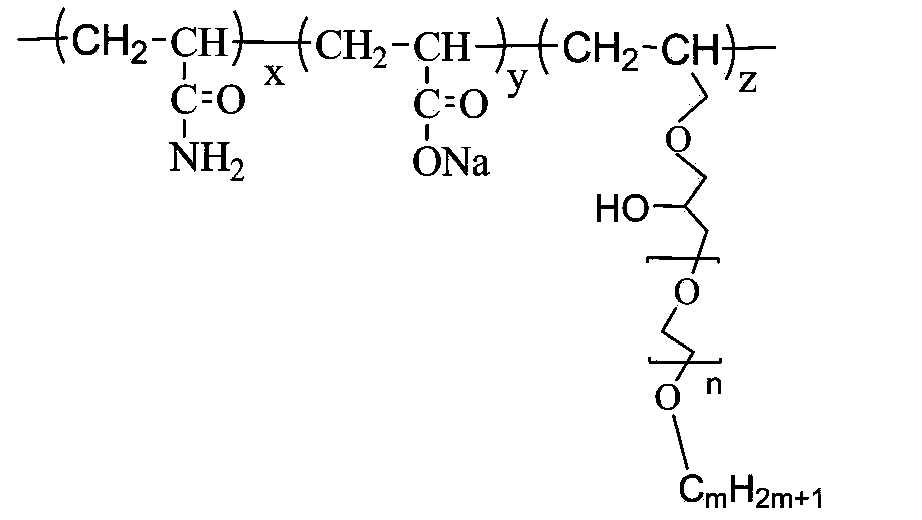

Water-soluble polymer for emulsifying and visbreaking viscous oil and preparation method thereof

A water-soluble polymer, emulsifying and viscosity-reducing technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as poor fluidity of crude oil, reduce viscosity of heavy oil, easily obtain raw materials, and synthesize methods. Convenient and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of monomeric allyl glyceryl ether-based polyoxyethylene ether-based alkane compounds:

[0027] Dissolve 1 volume of alkyl (12 carbon atoms) polyoxyethylene ether in 2 volumes of tetrahydrofuran, and add allyl glycidyl ether dropwise to the tetrahydrofuran solution under nitrogen, and the alkyl polyoxyethylene The molar ratio of vinyl ether to allyl glycidyl ether is 1:1. After reacting at 70-80°C for 5 hours, the product is distilled under reduced pressure to obtain a brown viscous liquid.

[0028] The monomer was uniformly mixed with spectrally pure KBr, pressed into tablets, and the infrared spectrum of the monomer was measured with an infrared spectrometer.

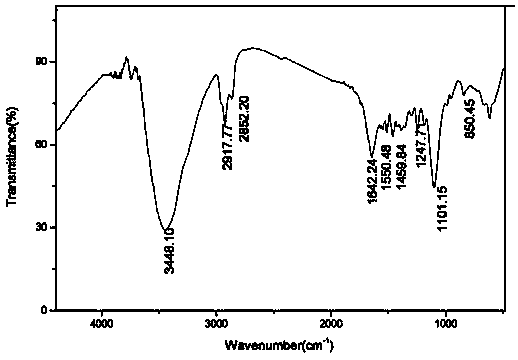

[0029] figure 1 It is the infrared spectrogram of allyl glyceryl ether base polyoxyethylene ether base alkane compound, from figure 1 It can be seen that at 3447cm -1 、2914cm -1 and 2850cm -1 at -OH and -CH-(-CH 2 -) The stretching vibration peak of the group is at 1642cm -1 at -HC=CH 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com