Hydrophobic oleophobic microporous membrane paster for protection of welded car lamp and manufacturing method thereof

A hydrophobic and oleophobic, microporous film technology, applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problem of the reduced ability of the light ventilation and convection to adjust the humidity of the light, airtight, no self-cleaning and other problems, to achieve a good effect of automobile exhaust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

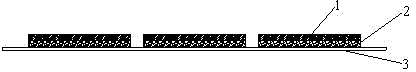

[0021] A hydrophobic and oleophobic microporous film patch for welded car lamp protection, comprising: an organic fluorine hydrophobic and oleophobic finishing agent 1, a microporous film 2 of expanded polytetrafluoroethylene and a low-viscosity PE tape 3, the One side of the expanded polytetrafluoroethylene microporous film 2 is coated with an organic fluorine hydrophobic and oleophobic finishing agent 1, and the other side of the expanded polytetrafluoroethylene microporous film 2 is pasted with low-viscosity PE tape3.

[0022] The organic fluorine hydrophobic and oleophobic finishing agent 1 includes the following raw materials in parts by weight: 50% dodecafluoroheptyl methacrylate, 2% hydroxyethyl methacrylate, 40% emulsifier and ammonium persulfate initiator 8 %, the emulsifier includes nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate, and the weight ratio of nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate is 3: 2.

Embodiment 2

[0024] A hydrophobic and oleophobic microporous film patch for welded car lamp protection, comprising: an organic fluorine hydrophobic and oleophobic finishing agent 1, a microporous film 2 of expanded polytetrafluoroethylene and a low-viscosity PE tape 3, the One side of the expanded polytetrafluoroethylene microporous film 2 is coated with an organic fluorine hydrophobic and oleophobic finishing agent 1, and the other side of the expanded polytetrafluoroethylene microporous film 2 is pasted with low-viscosity PE tape3.

[0025] The organic fluorine hydrophobic and oleophobic finishing agent 1 includes the following raw materials in parts by weight: 40% dodecafluoroheptyl methacrylate, 3% hydroxyethyl methacrylate, 50% emulsifier and ammonium persulfate initiator 7 %, the emulsifier includes nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate, and the weight ratio of nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate is 3: 2.

Embodiment 3

[0027] A hydrophobic and oleophobic microporous film patch for welded car lamp protection, comprising: an organic fluorine hydrophobic and oleophobic finishing agent 1, a microporous film 2 of expanded polytetrafluoroethylene and a low-viscosity PE tape 3, the One side of the expanded polytetrafluoroethylene microporous film 2 is coated with an organic fluorine hydrophobic and oleophobic finishing agent 1, and the other side of the expanded polytetrafluoroethylene microporous film 2 is pasted with low-viscosity PE tape3.

[0028] The organic fluorine hydrophobic and oleophobic finishing agent 1 includes the following raw materials in parts by weight: 60% dodecafluoroheptyl methacrylate, 1% hydroxyethyl methacrylate, 30% emulsifier and ammonium persulfate initiator 9 %, the emulsifier includes nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate, and the weight ratio of nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate is 3: 2.

[0029] A me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com