Antirust transparent cutting fluid and preparation method thereof

A cutting fluid, transparent technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of lubrication, poor rust resistance, poor rust resistance, endangering the health of operators, etc., and achieve good corrosion resistance and rust resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

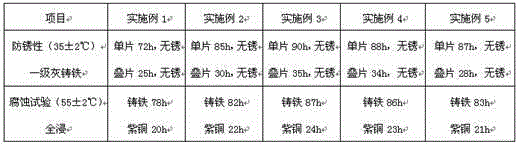

Examples

Embodiment 1

[0015] A kind of antirust transparent cutting fluid, comprising by weight components: 3 parts of triethanolamine, 1 part of polyethylene glycol 2000, 0.2 part of trisodium phosphate, 0.2 part of polyglycerol fatty acid, 0.5 part of sodium thiosulfate, 2 parts of glycerin , 1 part of sodium carbonate, and 80 parts of water.

[0016] The above-mentioned anti-rust transparent cutting fluid is prepared according to the following steps:

[0017] (1) Weigh each component according to parts by weight;

[0018] (2) Heat the water to 60°C, add each component, stir at 70 rpm for 30 minutes to dissolve and cool down to room temperature to obtain anti-rust transparent cutting fluid.

Embodiment 2

[0020] A kind of anti-rust transparent cutting fluid, comprising by weight components: 5 parts of triethanolamine, 2 parts of polyethylene glycol 2000, 0.4 part of trisodium phosphate, 0.3 part of polyglycerol fatty acid, 0.6 part of sodium thiosulfate, 3 parts of glycerin , 2 parts of sodium carbonate, and 83 parts of water.

[0021] The above-mentioned anti-rust transparent cutting fluid is prepared according to the following steps:

[0022] (1) Weigh each component according to parts by weight;

[0023] (2) Heat water to 65°C, add each component, stir at 75 rpm for 35 minutes to dissolve and cool down to room temperature to obtain anti-rust transparent cutting fluid.

Embodiment 3

[0025] A kind of antirust transparent cutting fluid, comprising by weight components: 6 parts of triethanolamine, 3 parts of polyethylene glycol 2000, 0.6 part of trisodium phosphate, 0.4 part of polyglycerol fatty acid, 0.7 part of sodium thiosulfate, 4 parts of glycerin , 3 parts of sodium carbonate, 84 parts of water.

[0026] The above-mentioned anti-rust transparent cutting fluid is prepared according to the following steps:

[0027] (1) Weigh each component according to parts by weight;

[0028] (2) Heat the water to 68°C, add each component, stir at 78 rpm for 36 minutes to dissolve and cool down to room temperature to obtain anti-rust transparent cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com