Ceramic treatment formula and process for surface treatment of magnesium alloy vehicle hub

A technology of surface treatment and magnesium alloy, applied in the direction of coating, electrolytic coating, etc., can solve the problems of high process cost, falling off blocks, easy oxidation, etc., and achieve the effect of low process cost, less consumption and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

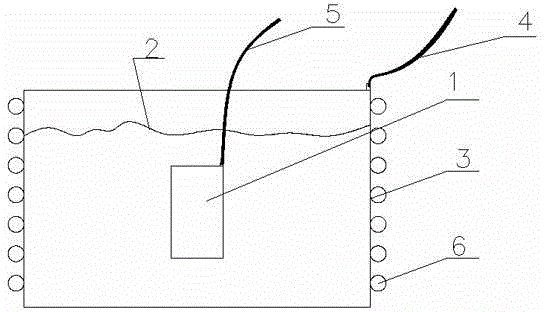

Image

Examples

Embodiment 2

[0037] The formula of crystal porcelain liquid is prepared according to the following weight percentage:

[0038] EDTA is 6%, SDBS is 2%, KOH is 8%, Nb-Re is 4%, Na 2 B 4 o 3 12%, V 4 o 6 is 2%, Mo-V is 2%, and the rest is water.

Embodiment 3

[0040] The formula of crystal porcelain liquid is prepared according to the following weight percentage:

[0041] EDTA is 5%, SDBS is 1%, KOH is 6%, Nb-Re is 2%, Na 2 B 4 o 3 5%, V 4 o 6 is 1%, M0-V is 1%, and the rest is water.

Embodiment 4

[0043] The formula of crystal porcelain liquid is prepared according to the following weight percentage:

[0044] EDTA is 8%, SDBS is 4%, KOH is 10%, Nb-Re is 6%, Na 2 B 4 o 3 15%, V 4 o 6 3% for Mo-V, 3% for Mo-V, and water for the rest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com