Aerospace cable

A cable and cable core technology, applied in the field of aerospace cables, can solve the problems of deformation of insulation layer and sheath, change of conductor center distance, weather resistance, non-flammability, chemical resistance and other properties cannot be taken into account at the same time. The effect of excellent oil resistance, good electrical properties, excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

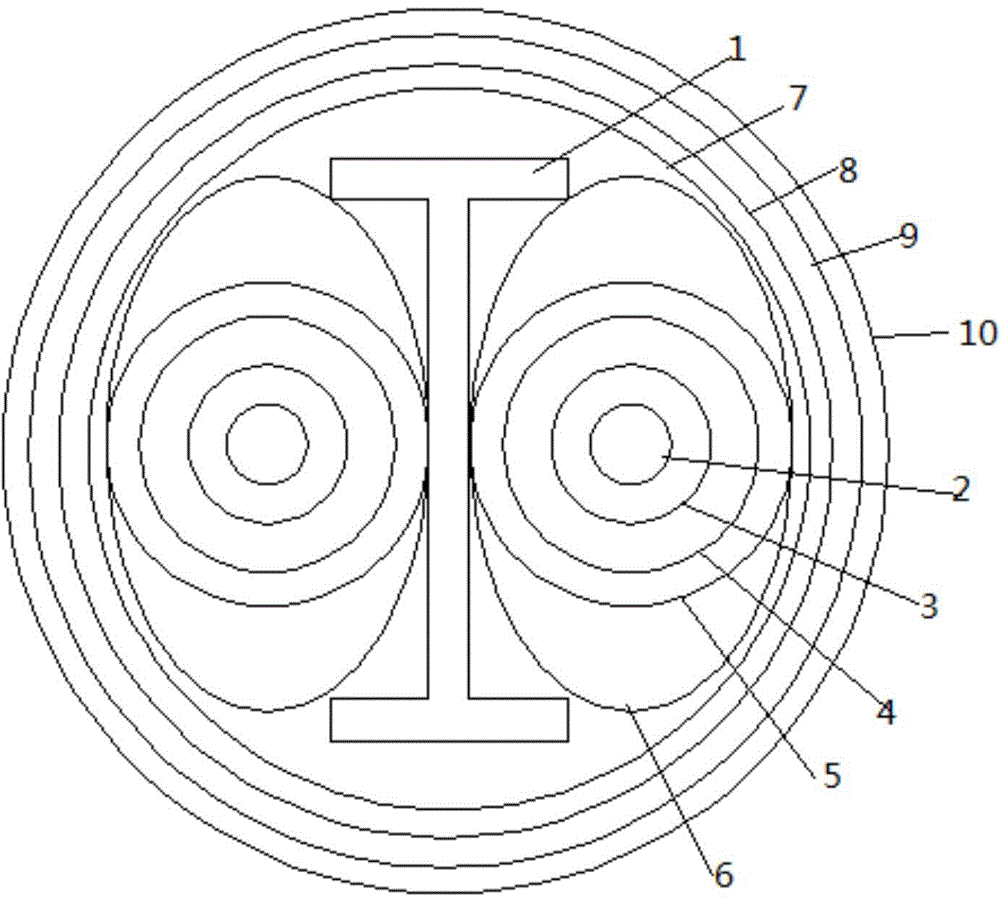

[0012] Such as figure 1 As shown, a kind of aerospace cable includes a cable core, and the cable core includes an I-shaped nylon skeleton 1, and wire cores are respectively placed on the left and right sides of the I-shaped nylon skeleton 1, and the wires are The core includes a conductor 2, and the outer side of the conductor 2 is covered with a foamed plastic insulating layer 3, a copper wire winding layer 4 and an aluminum tape interlocking armor layer 5, and the outer side of the conductor 2 is also covered with an oval nylon The skeleton 6 is covered with a tensile tape 7 , a plastic film 8 , a galvanized steel wire braided shielding layer 9 and an outer sheath 10 on the outside of the cable core in sequence.

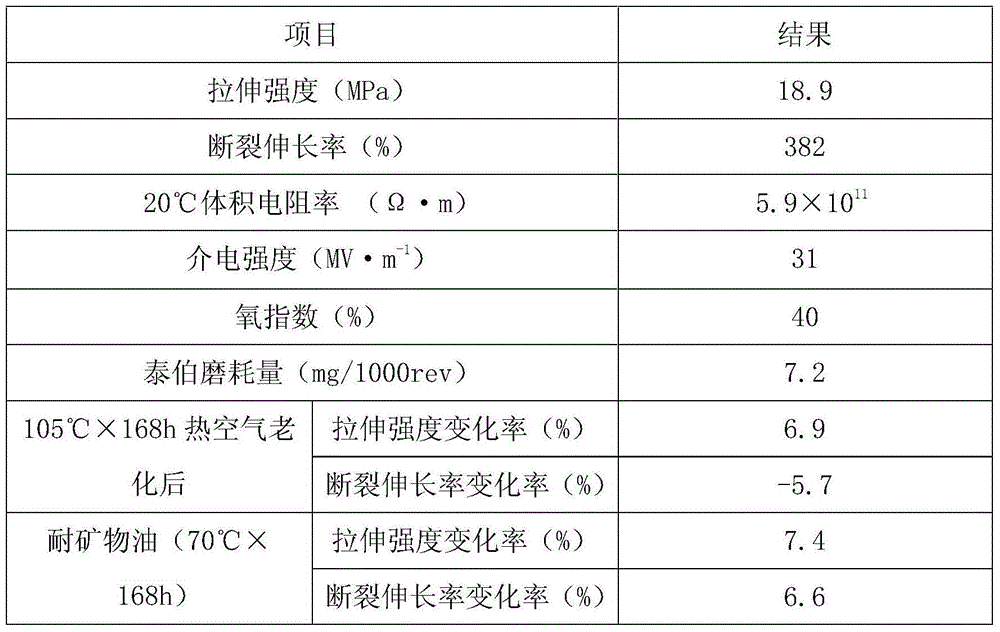

[0013] The material of the outer sheath 10 is made of the following raw materials in parts by weight: methyl vinyl phenyl silicone rubber 62, butadiene-vinyl pyridine rubber 38, acrylate rubber 24, coumarone resin 12, magnesium hydroxide 18, Molybdenum trioxide 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com