Method for controlling microbes in algae powder by combination of pasteurization and spray drying

A microbial and pasteurization technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as insignificant effects, poor applicability, and changes in the quality of algal flour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

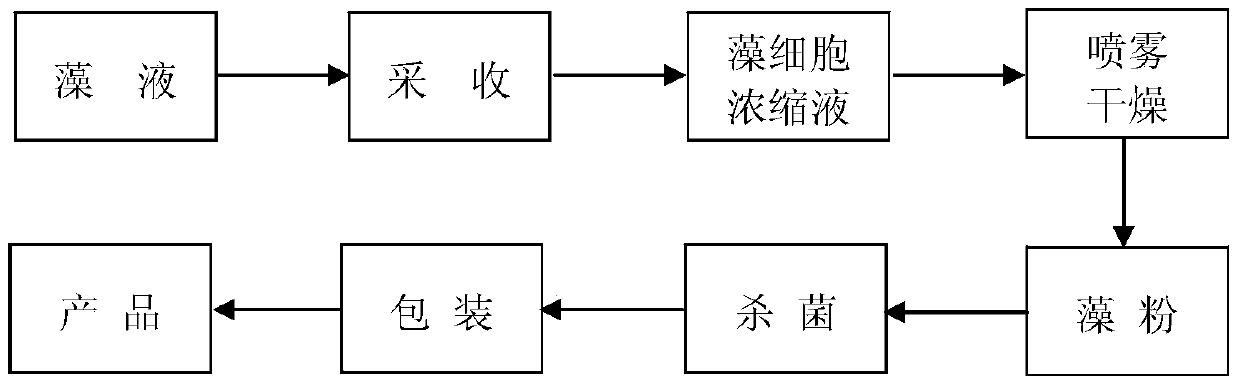

[0058] Embodiment 1: implement sterilization by existing technology

[0059] Proceed as follows:

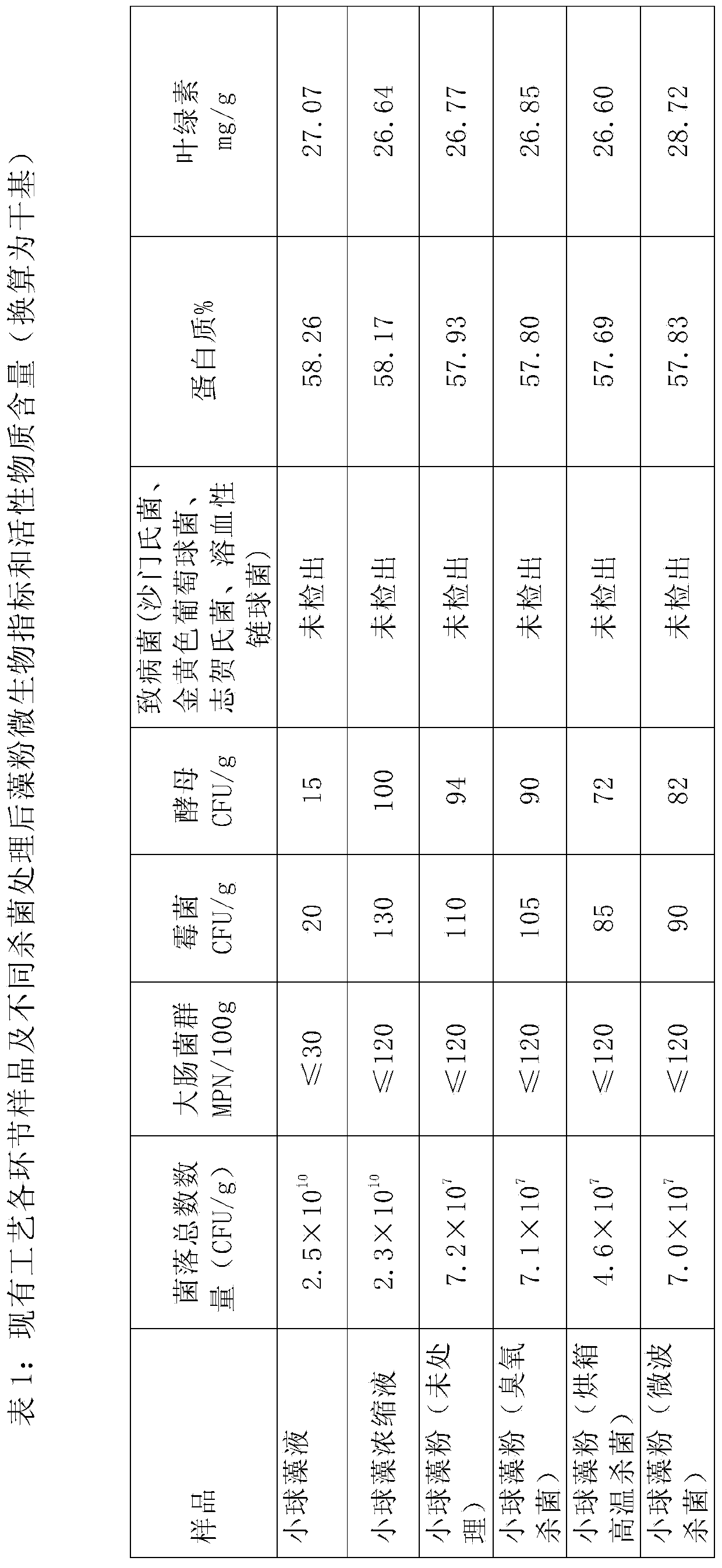

[0060] (1) Adopt the "heterotrophic-dilution-light-induced" technology (refer to Chinese invention patent: ZL200610025618.9) to cultivate and obtain the chlorella algae liquid. After measurement, the microbial indicators (converted to dry basis) are: the total number of colonies 2.5× 10 10 CFU / g, coliform group ≤30MPN / 100g, mold 20CFU / g, yeast 15CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic streptococcus) were not detected;

[0061] (2) by centrifugal concentration (5000rpm, 10min), the concentrated solid content of chlorella after concentration is 14.3% (percentage by weight), after measuring, microbial index (converted to dry basis) is respectively: total number of colonies 2.3 * 10 10 CFU / g, coliform group ≤120MPN / 100g, mold 130CFU / g, yeast 100CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic streptococcus...

Embodiment 2

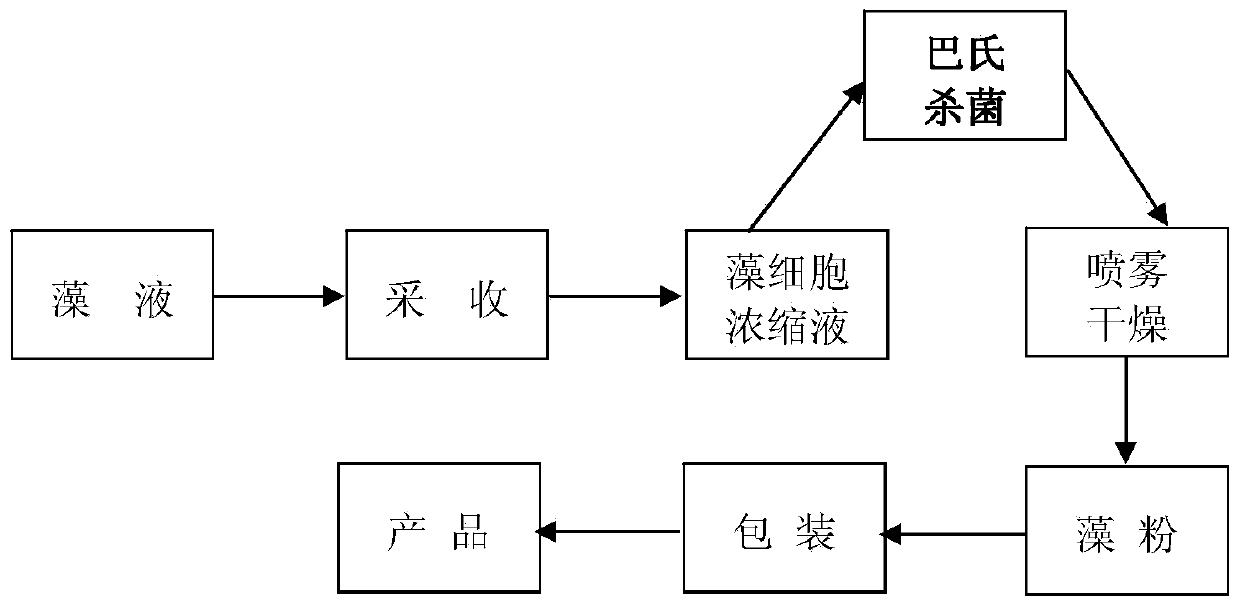

[0069] Embodiment 2: the sterilization implemented by technical scheme of the present invention

[0070] (1) According to the "heterotrophic-dilution-light-induced" technology to cultivate the chlorella algae liquid (see Chinese invention patent: ZL200610025618.9), after determination, the microbial indicators (converted to dry basis) are: the total number of colonies 2.5 × 10 10 CFU / g, coliform group ≤30MPN / 100g, mold 20CFU / g, yeast 15CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shigella, hemolytic streptococcus) were not detected;

[0071] (2) Collect and concentrate the chlorella algae liquid by centrifugation (5000rpm, 10min), the concentrated solid content of chlorella after concentration is 14.3% (percentage by weight), after measuring, the microbial index (converted to dry basis) is respectively : Total number of colonies 2.3×10 10 CFU / g, coliform ≤120MPN / 100g, mold 130CFU / g, yeast 100CFU / g, pathogenic bacteria (Salmonella, Staphylococcus aureus, Shig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com