One-dimensional high-defect NiO nanowires prepared by electrostatic spinning and catalytic application thereof

A technology of nanowires and defects, which is applied in the field of preparation of high-defect NiO nanowires, and can solve problems such as the reduction of crystal surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in further detail below. It should be noted that the various embodiments of the present invention can be combined in any way as desired.

[0020] The first aspect of the present invention provides a method for preparing one-dimensional NiO nanowires, which uses nickel acetate, N-N dimethylformamide and polyvinylpyrrolidone as precursors for the reaction.

[0021] In a preferred embodiment, the preparation method comprises the steps of:

[0022] (1) Weigh a certain amount of nickel acetate (Ni(CH 3 COO) 2 4H 2 O), dissolved in a certain amount of N-N dimethylformamide (DMF), stirred for a certain period of time.

[0023] (2) Then weigh a certain amount of polyvinylpyrrolidone (PVP) and dissolve it in the solution of nickel acetate, and stir for several hours.

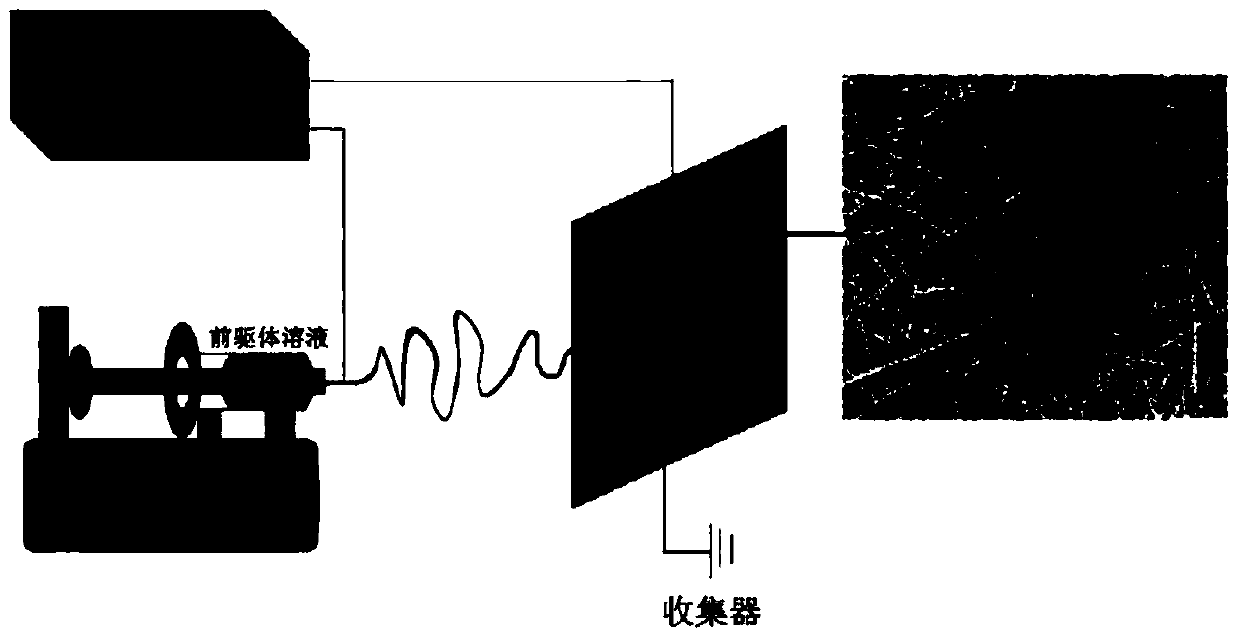

[0024] (3) Take the precursor solution into the syringe, move it to the syringe pump, apply a certain flow rate and voltage, and obtain Ni(CH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com