Method for performing coagulation treatment on waste paper pulping comprehensive papermaking wastewater by utilizing cellulose-based flocculating agent

A technology for pulping and papermaking and comprehensive wastewater, which is applied in chemical instruments and methods, wastewater treatment in processing, multi-stage water/sewage treatment, etc., can solve the problems of high operation cost and low treatment efficiency, and achieve low operation cost and high treatment efficiency. The effect is obvious and the process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

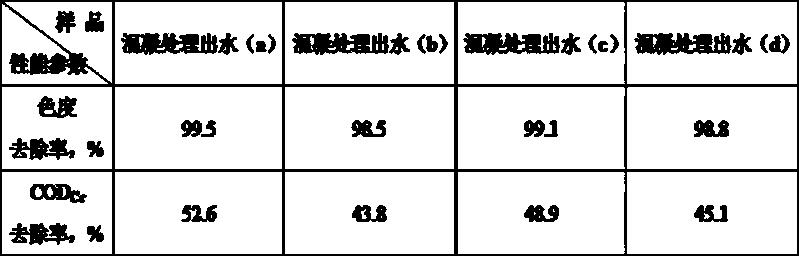

Embodiment 1

[0019] 1) Filter the pulping and papermaking comprehensive waste water of carton factory leftovers through a 60-mesh inclined sieve, and the inclined sieve is installed at an angle of 40 degrees to obtain pre-filtered waste water with a solid particle size of less than or equal to 0.3 mm;

[0020] 2) Add 0.5 mg / L polyaluminum chloride to the pre-filtered wastewater obtained in step 1), stir rapidly for 15 minutes, and settle for 15 minutes after stirring evenly, and separate the mud and water to get the supernatant, which is the effluent of the destabilization sedimentation treatment;

[0021] 3) Add 30 mL / L 2.5% CaCl to the destabilized precipitation treatment effluent obtained in step 2) 2 solution and 450 mg / L reed cellulose-based flocculant, stirred rapidly at 200 rpm for 3 min, then reduced the stirring speed to 80 rpm, added 0.1 mol / L dilute hydrochloric acid solution to adjust the pH of the solution to 3, and added 15 mL / L 2.5% CaCl 2 Solution, continue to stir slowly ...

Embodiment 2

[0023] 1) Filter the white paper trimming pulping and papermaking comprehensive wastewater of the printing factory through a 60-mesh inclined sieve, and the inclined sieve is installed at an angle of 40 degrees to obtain pre-filtered wastewater with a solid particle size of less than or equal to 0.3 mm;

[0024] 2) Add 0.8 mg / L polyaluminum chloride to the pre-filtered wastewater obtained in step 1), stir rapidly for 12 minutes, and settle for 10 minutes after stirring evenly, and separate the mud and water to get the supernatant, which is the effluent of the destabilization sedimentation treatment;

[0025] 3) Add 20 mL / L 2.5% CaCl to the destabilized precipitation treatment effluent obtained in step 2) 2 solution and 550 mg / L straw cellulose-based flocculant, stirred rapidly at 200 rpm for 3 min, then reduced the stirring speed to 80 rpm, added 0.1 mol / L dilute hydrochloric acid solution to adjust the pH of the solution to 5, and added 10 mL / L 2.5 % CaCl 2 Solution, continu...

Embodiment 3

[0027] 1) Filter the mixed waste paper and miscellaneous waste paper pulping and papermaking comprehensive wastewater through a 60-mesh inclined sieve with an installation angle of 40 degrees to obtain pre-filtered wastewater with a solid particle size of less than or equal to 0.3 mm;

[0028] 2) Add 1.5 mg / L polyaluminum chloride to the pre-filtered wastewater obtained in step 1), stir rapidly for 8 minutes, and settle for 30 minutes after stirring evenly, and separate the mud and water to get the supernatant, which is the effluent of the destabilization sedimentation treatment;

[0029] 3) Add 15 mL / L 2.5% CaCl to the destabilized precipitation treatment effluent obtained in step 2) 2 solution and 700 mg / L rice straw cellulose-based flocculant, stirred rapidly at 200 rpm for 5 min, then reduced the stirring speed to 80 rpm, added 0.1 mol / L dilute hydrochloric acid solution to adjust the pH of the solution to 4, and added 30 mL / L 2.5 % CaCl 2 Solution, continue to stir slowl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com