Polyurethane flame-retardant resilient foam

A polyurethane and foam technology, applied in the field of materials, can solve the problems of unsatisfactory high resilience performance of foam and lack of flame retardant ability, and achieve the effect of wide range of use, easy access, and fast rebound speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

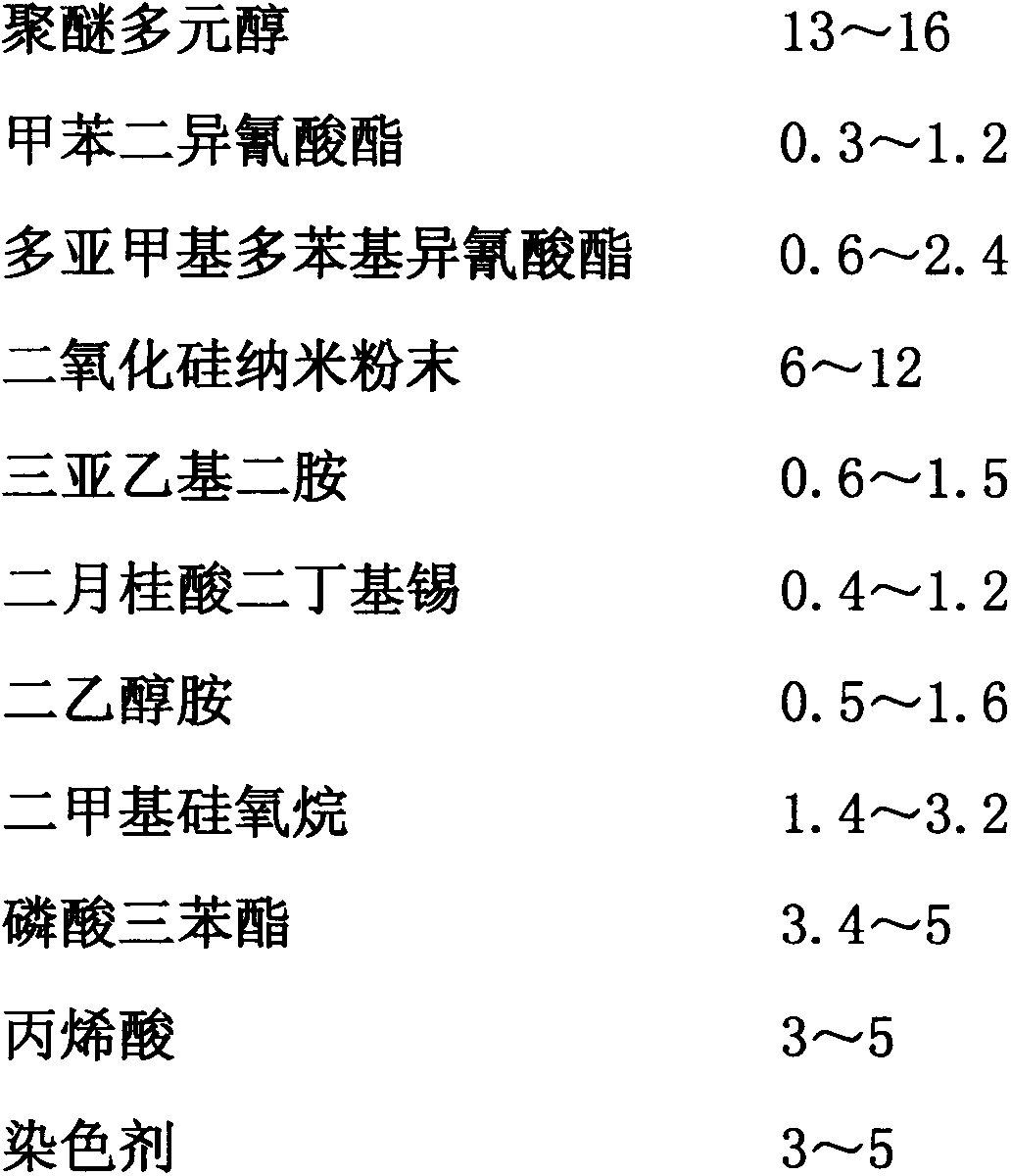

Image

Examples

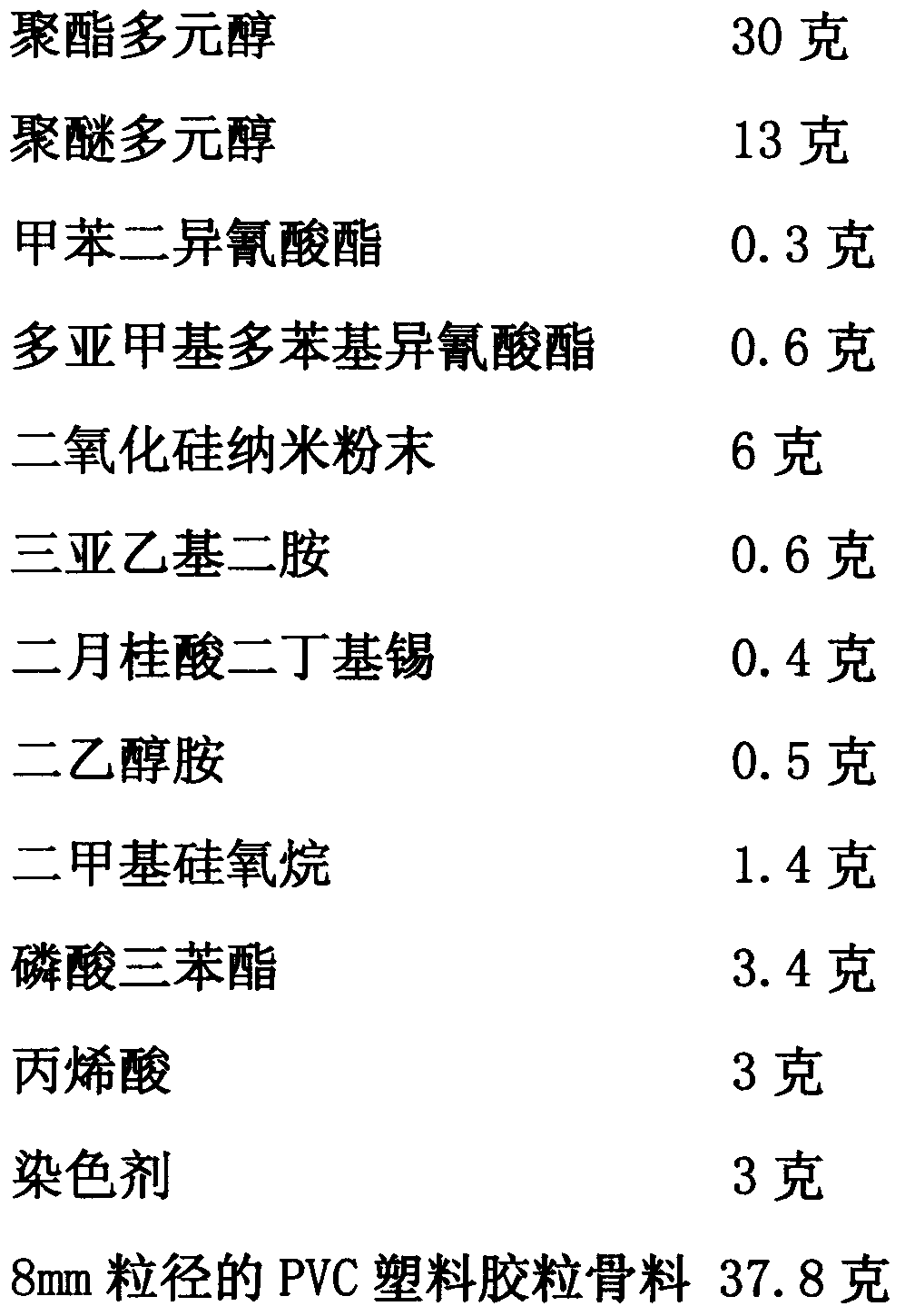

Embodiment 1

[0018] The polyurethane flame-retardant rebound foam in the present embodiment is made of following components:

[0019]

[0020] Wherein the acrylic acid is used as a crosslinking agent, the dibutyltin dilaurate is used as a tin catalyst, the diethanolamine is used as an amine catalyst, and the dimethylsiloxane is used as a foam stabilizer.

[0021] The polyurethane flame-retardant rebound foam in the present embodiment comprises the following steps during preparation:

[0022] 1) The PVC block material is crushed by wind selection centrifugal classifier, and the crushed material enters the rotary sieve, that is, the grading screen under the action of the fan, and the PVC rubber aggregate with a particle size of 8mm is acted on by the brush and the screen. Pass through the screen and collect through the fine material port.

[0023] 2), weigh 30 grams of polyester polyol, 13 grams of polyether polyol, 0.3 grams of toluene diisocyanate, 0.6 grams of polymethylene polyphenyl...

Embodiment 2

[0026] The difference between the polyurethane flame-retardant rebound foam in this embodiment and the polyurethane flame-retardant rebound foam in Example 1 lies in the change of the content of the components. The polyurethane flame-retardant rebound foam in this embodiment is composed of:

[0027]

[0028]

[0029] The polyurethane flame-retardant rebound foam in the present embodiment comprises the following steps during preparation:

[0030] 1), weigh phenyl o-hydroxybenzoate ultraviolet absorber, fatty alcohol polyoxyethylene ether, acrylic acid, dyeing agent, absolute ethanol, put into the container successively for use;

[0031] 2), after mixing the weighed phenyl o-hydroxybenzoate ultraviolet absorber, fatty alcohol polyoxyethylene ether, acrylic acid, dyeing agent, and absolute ethanol, stir for 70 minutes, and the ambient temperature during stirring is 30°C;

[0032] 3), at room temperature, send the above-mentioned suspension into a high-shear disperser to dis...

Embodiment 3

[0035] The difference between the polyurethane flame-retardant rebound foam in this embodiment and the polyurethane flame-retardant rebound foam in Example 1 lies in the change of the content of the components. The polyurethane flame-retardant rebound foam in this embodiment is composed of:

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com