Method and device for controlling air quality in henhouse of hen farm

A technology for quality control and internal air, which is applied in the poultry industry, poultry cages or houses, applications, etc., can solve the secondary pollution of fresh air, does not take into account the adverse effects of gas pollutants, and cannot ensure that the environment in the chicken house can meet the needs of chickens at any time. Health requirements and other issues to prevent secondary pollution, improve chicken health and production performance, and improve the air quality in the house

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

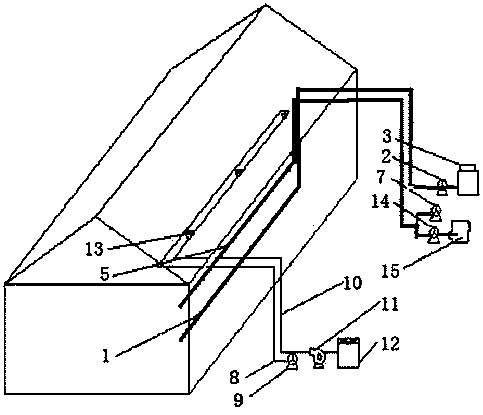

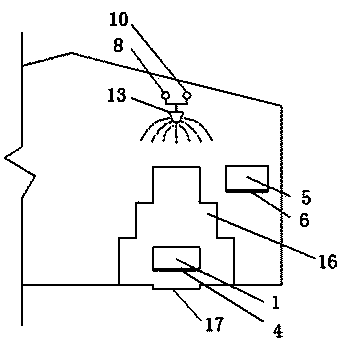

[0028] In this embodiment, the sewage air duct 1 is adjacent to the top of the excrement tank 17, and the bottom surface of the horizontal section in the sewage air duct 1 is provided with a longitudinal slit-type suction tuyere 4, and the gas pollutants produced by the feces are immediately discharged from the suction tuyere 4. Inhaled, the gaseous pollutants are driven by the induced draft fan 2, and are discharged into the scrubber 3 along the exhaust air duct 1, and the tail gas treated by the scrubber 3 is finally discharged to the environment, thereby effectively reducing the pollution generated in the chicken house. The impact of gaseous pollutants on the atmospheric environment. At the same time, for every 1m increase in the sewage air duct along the direction of the sewage flow, the diameter of the suction air outlet 4 is reduced by 0.1cm, which can ensure that the gas pollutants are evenly sucked into the sewage air duct and led to the washing tower outside the house....

Embodiment 2

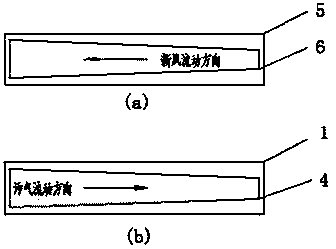

[0032] In this embodiment, a longitudinal slit-type suction air outlet 4 is provided on the side of the horizontal section of the sewage air duct 1, and along the flow direction of the sewage air, for every 1m increase in the sewage air duct pipeline, the diameter of the suction air outlet decreases by 0.3 cm. The position height of fresh air duct 5 is equal to chicken coop 16, and the horizontal distance with sewage air duct 1 is 150cm, and vertical slit type air supply air outlet 6 is arranged on the side of the horizontal section in fresh air duct 5 houses. In the flow direction, for every 1m increase in the fresh air duct, the diameter of the air supply outlet 6 will increase by 0.3cm.

[0033] In the atomization system, an atomization water pipe 10 and an atomization air pipe 8 are installed at a distance of 30 cm from the top of the chicken house, and the atomization water pipe 10 and the atomization air pipe 8 are located directly above the chicken coop 16, and the atom...

Embodiment 3

[0035] In this embodiment, the bottom surface of the horizontal section of the sewage air duct 1 is provided with a longitudinal slit suction air outlet 4, and along the flow direction of the sewage gas, for every 1m increase in the sewage air duct pipeline, the diameter of the suction air outlet decreases by 0.6 cm. The position height of fresh air duct 5 is equal to chicken coop 16, and the horizontal distance with sewage air duct 1 is 130cm, and the bottom surface of the horizontal section in the fresh air duct 5 house is provided with longitudinal slit type air supply air outlet 6, meanwhile, along the fresh air In the flow direction, for every 1m increase in the fresh air duct, the diameter of the air supply outlet 6 will increase by 0.6cm.

[0036] In the atomization system, an atomization water pipe 10 and an atomization air pipe 8 are installed at a distance of 30 cm from the top of the chicken house, and the atomization water pipe 10 and the atomization air pipe 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com