Material automatic warehouse-in-out and intelligent storing device

A technology of automatic access and sorting device, applied in the field of access and intelligent sorting equipment, automatic warehousing, can solve the problems of multi-work efficiency of workers, error-prone manual sorting, and sluggish materials, etc. / The effect of high fetching efficiency, shortened material preparation time, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

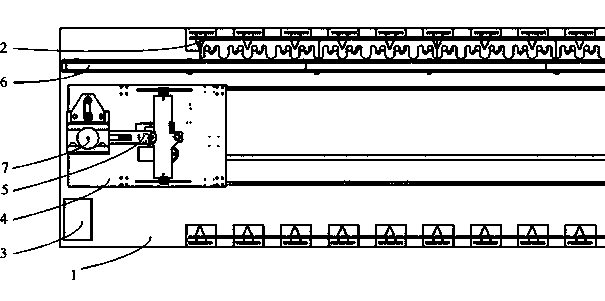

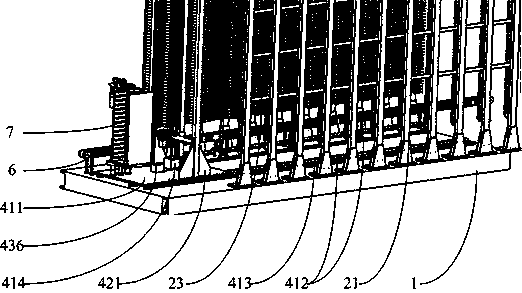

[0024] combine Figure 1-2 As shown, a material automatic access and intelligent sorting device in this embodiment includes: a complete machine base 1, material shelves 2 on both sides of the material tray, a roadway machine 4, and an automatic machine attached to the roadway machine 4. Loading machine 7, material access robot with left and right steering function 5, material conveying belt line 6, industrial control computer (built-in motion control card) 3, and external upper computer for man-machine operation.

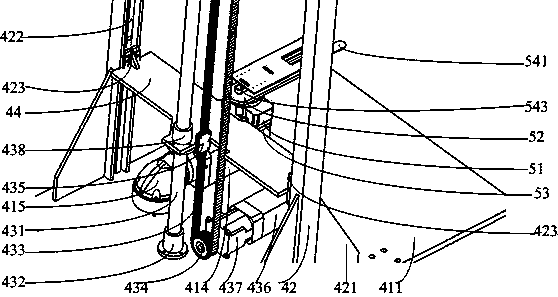

[0025] An iron plate with a certain thickness is laid on the base 1, and three iron bar bosses are welded on it, so that the linear guide rail 412 and the transmission rack 413 of the roadway machine 4 are installed. image 3 It is a structural schematic diagram of the roadway machine of the automatic material access and intelligent sorting device of the present invention. The roadway machine 4 includes four linear guide rail sliders 41, a support base plate 411...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com