A coal gasification slag purification process and a system for realizing the process

A technology for coal gasification slag and slag, which is applied in the petroleum industry, chemical instruments and methods, fuels, etc., can solve the problems of incomplete coal recovery and treatment, and achieve the effects of full utilization of energy, low equipment operation cost and high dehydration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

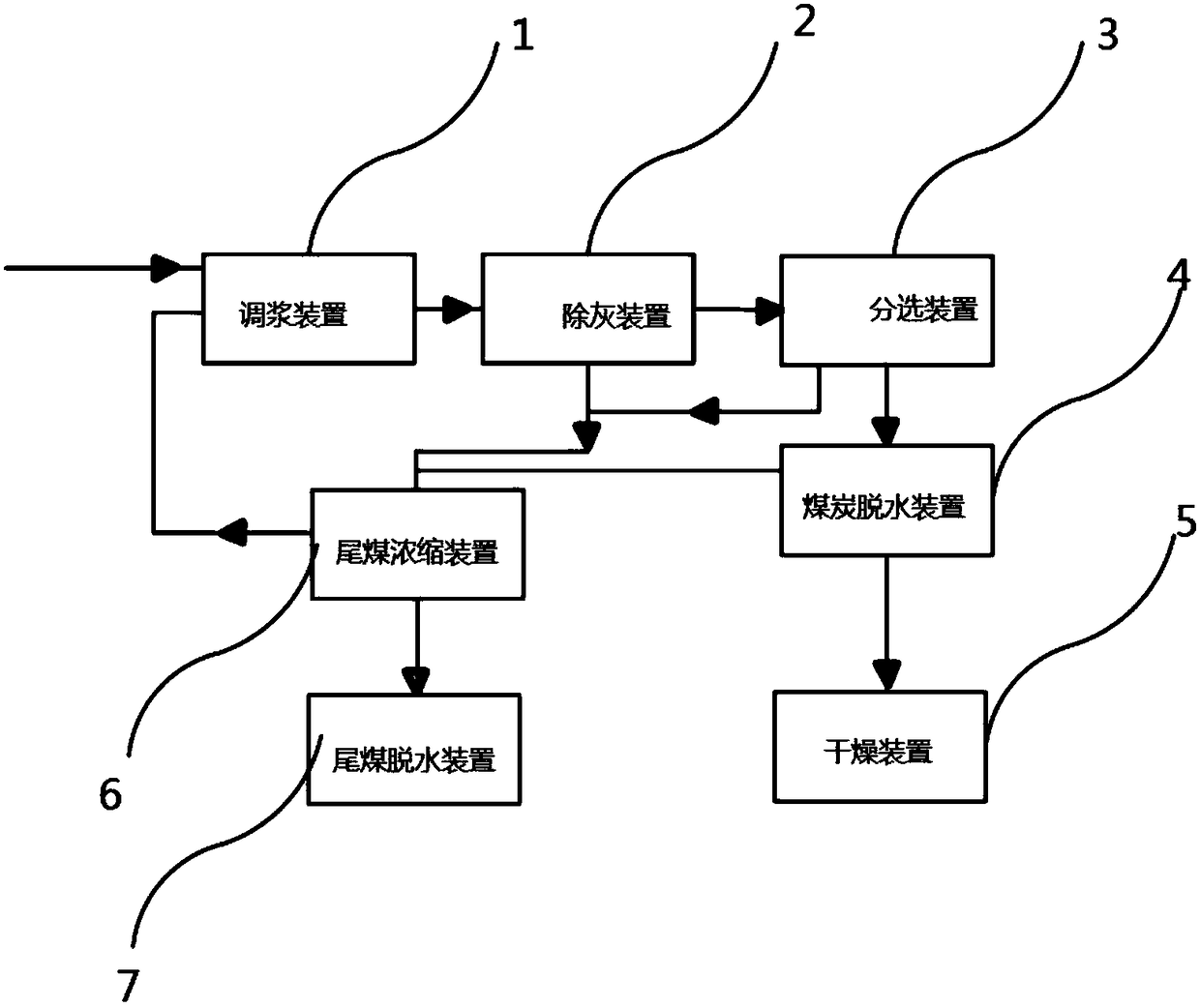

[0021] Embodiment 1, the coal gasification slag purification process with a particle size of 0.5mm or less includes the following steps. First, the coal gasification slag is passed into the ash removal device 2 for ash removal, which can be realized by the ash removal device in the prior art. so as to get A d More than 60% high ash slag and A d Less than 60% low ash slag, the A d Refers to the dry base ash. That is to say, the proportion of the residue after complete combustion in a dry state. then A d The high-ash slag greater than 60% is discharged and sent to the coal gasification slag stacking site for treatment; then the low-ash slag with Ad less than 60% is sorted by a sorting device to obtain A d Less than 40% of clean coal, tailings or intermediates, intermediates refer to products whose ash content index in the sorting process is higher than the ash content requirements of concentrate ore and lower than the ash content requirements of tailings. The clean coal menti...

Embodiment 2

[0022] Example 2, on the basis of the above technical solution, the coal gasification slag with a particle size of 0.5 mm or less is prepared into a slurry with a concentration of 0-500 g / L. Then deash the coal gasification slag with particle size below 0.5mm to obtain A d More than 60% high ash pulp and A d Less than 60% low ash pulp; A d Less than 60% of the low ash pulp is sorted to obtain d Less than 40% of the clean coal, tailings, intermediates, and intermediates are returned to the sorting device for re-separation, and the clean coal and tailings are processed in the next step; the clean coal is dehydrated; the dehydrated clean coal is dried to obtain Coal with a water content of less than 20%; the tailings are concentrated to achieve solid-liquid separation. The high-ash slag that does not contain coal or has low coal content is removed by ash removal to reduce the energy consumption of clean coal dehydration and drying in the later stage; A d Less than 40% of clea...

Embodiment 4

[0024] Embodiment 4 Further, on the basis of the above technical solution, the impurity and ash removal device 1 is a slag grinder. By using the ash removal device as a slag grinder, the impurity removal is more thorough, and the energy consumption of dehydration and drying in the later stage is smaller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com