Purification device and method for carbon nanotube purification

A purification device and technology of carbon nanotubes, applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of unsuitability for large-scale production, high cost of complexing agents, complex processes, etc., and achieve rapid and thorough catalyst Ease of mass production, simple operation and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

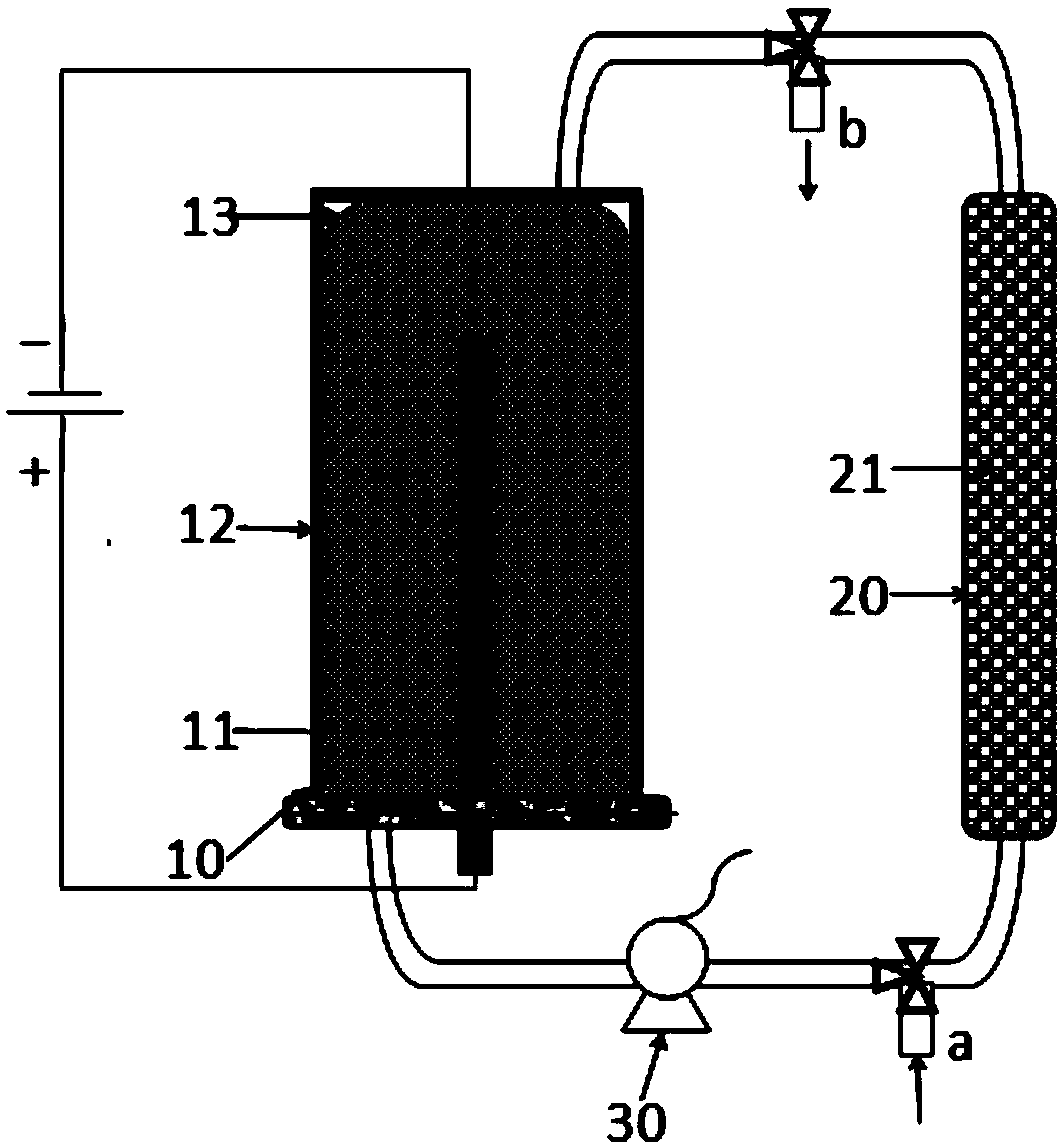

[0051] Embodiment 1: the purification method of the carbon nanotube of the present embodiment, its steps are as follows:

[0052] First, fill the carbon nanotubes that need to be purified into the filter bag in the cathode chamber, then insert the anode electrode into the carbon nanotubes, follow the instructions figure 1 Connect the rest of the device; connect the entire device circuit, turn on the circulation pump, pump 2% sulfuric acid solution from the valve port of the second three-way valve a to fill the entire circuit, and rotate the second three-way valve a to connect the entire circuit , turn on the power supply of the oxidation tank, adjust the voltage to 2-4V, adjust the current to 0.5-0.8A, and carry out ion exchange while oxidizing; after 30 minutes, a small amount of electrolyte is taken from the valve port of the first three-way valve b from time to time, and detected For the metal ions in it, when no metal ions are detected, disconnect the power supply of the o...

Embodiment 2

[0054] Embodiment 2: the purification method of the carbon nanotube of the present embodiment, its steps are as follows:

[0055] First, fill the required purified carbon nanotubes into the filter bag in the cathode compartment, then insert the anode electrode into the carbon nanotubes, follow the instructions figure 1 Connect the rest of the device; connect the entire device circuit, turn on the circulation pump, pump 5% sulfuric acid solution from the second three-way valve a valve to fill the whole circuit, rotate the second three-way valve a valve, and connect the whole circuit , turn on the power supply of the oxidation tank, adjust the voltage to 1-3V, adjust the current to 0.3-0.5A, and carry out ion exchange while oxidizing; after 30 minutes, a small amount of electrolyte is taken from the valve port of the first three-way valve b from time to time, and the electrolyte is detected. When no metal ions are detected, disconnect the power supply of the oxidation pool, rota...

Embodiment 3

[0057] Embodiment 3: the purification method of the carbon nanotube of the present embodiment, its steps are as follows:

[0058] First, fill the required purified carbon nanotubes into the filter bag in the cathode compartment, then insert the anode electrode into the carbon nanotubes, follow the instructions figure 1 Connect the rest of the device; connect the entire device circuit, turn on the circulation pump, pump 10% sulfuric acid solution from the second three-way valve a valve port to fill the entire circuit, turn the a valve to connect the entire circuit, and connect the oxidation pool Power supply, the voltage is adjusted to 2-4V, the current is adjusted to 0.2-0.6A, and ion exchange is performed while oxidizing; after 30 minutes, a small amount of electrolyte is taken from the valve port of the first three-way valve b from time to time, and the metal ions in it are detected. When no metal ions are detected, disconnect the power supply of the oxidation pool, rotate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com