Electrolyte for high-safety aluminum air battery and preparation method of electrolyte

An aluminum-air battery, high-safety technology, applied in the field of electrochemistry, can solve the problems of cumbersome preparation process and high energy consumption, and achieve the effects of promoting oxidative dissolution and increasing discharge potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare 2 mol / L sodium chloride aqueous solution, add anhydrous gallium chloride, stir and dissolve, so that the concentration of anhydrous gallium chloride is 0.1 mol / L.

[0017] The prepared electrolyte is added to the aluminum-air battery, the negative electrode is industrial pure aluminum, the positive electrode is a commercial air electrode, and the main components are manganese dioxide, acetylene black, and nickel mesh. Connect the positive and negative electrodes of the battery to the electrochemical workstation for data collection, and calculate the mass loss of the aluminum sheet before and after discharge. The test results are as follows:

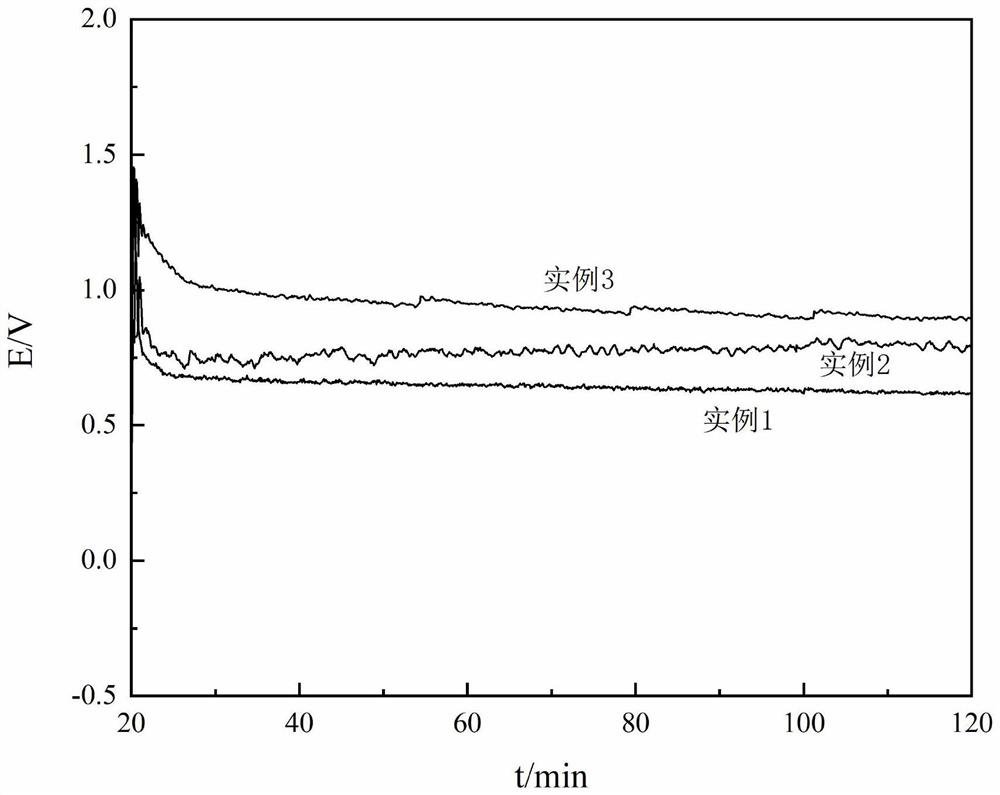

[0018] The measured discharge potential is 0.63V, the capacity density is 2242.90Ah / kg, and the energy density is 1428.10Wh / kg.

Embodiment 2

[0020] A 2 mol / L sodium chloride aqueous solution is prepared, anhydrous gallium chloride is added, and the solution is stirred to dissolve, so that the concentration of anhydrous gallium chloride is 0.15 mol / L.

[0021] The prepared electrolyte is added to the aluminum-air battery, the negative electrode is industrial pure aluminum, the positive electrode is a commercial air electrode, and the main components are manganese dioxide, acetylene black, and nickel mesh. Connect the positive and negative electrodes of the battery to the electrochemical workstation for data collection, and calculate the mass loss of the aluminum sheet before and after discharge. The test results are as follows:

[0022] The measured discharge potential is 0.79V, the capacity density is 1933.28Ah / kg, and the energy density is 1685.18Wh / kg.

Embodiment 3

[0024] A 2 mol / L sodium chloride aqueous solution was prepared, anhydrous gallium chloride was added, and the solution was stirred to dissolve, so that the concentration of anhydrous gallium chloride was 0.2 mol / L.

[0025] The prepared electrolyte is added to the aluminum-air battery, the negative electrode is industrial pure aluminum, the positive electrode is a commercial air electrode, and the main components are manganese dioxide, acetylene black, and nickel mesh. Connect the positive and negative electrodes of the battery to the electrochemical workstation for data collection, and calculate the mass loss of the aluminum sheet before and after discharge. The test results are as follows:

[0026] The measured discharge potential is 0.97V, the capacity density is 1482.42Ah / kg, and the energy density is 1762.22Wh / kg.

[0027] Test the discharge potential curve of each aluminum-air battery within 2h, and the test method of current density is as follows:

[0028] Connect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com