Patents

Literature

76 results about "Aminopolycarboxylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aminopolycarboxylic acid (sometimes abbreviated APCA) is a chemical compound containing one or more nitrogen atoms connected through carbon atoms to two or more carboxyl groups. Aminopolycarboxylates that have lost acidic protons form strong complexes with metal ions. This property makes aminopolycarboxylic acids useful complexone in a wide variety of chemical, medical, and environmental applications.

Polishing slurry and polishing method using same

InactiveUS20080076327A1High precisionHigh ratePigmenting treatmentPolishing machinesSilica particleNitrite

Owner:NIHON MICRO COATING

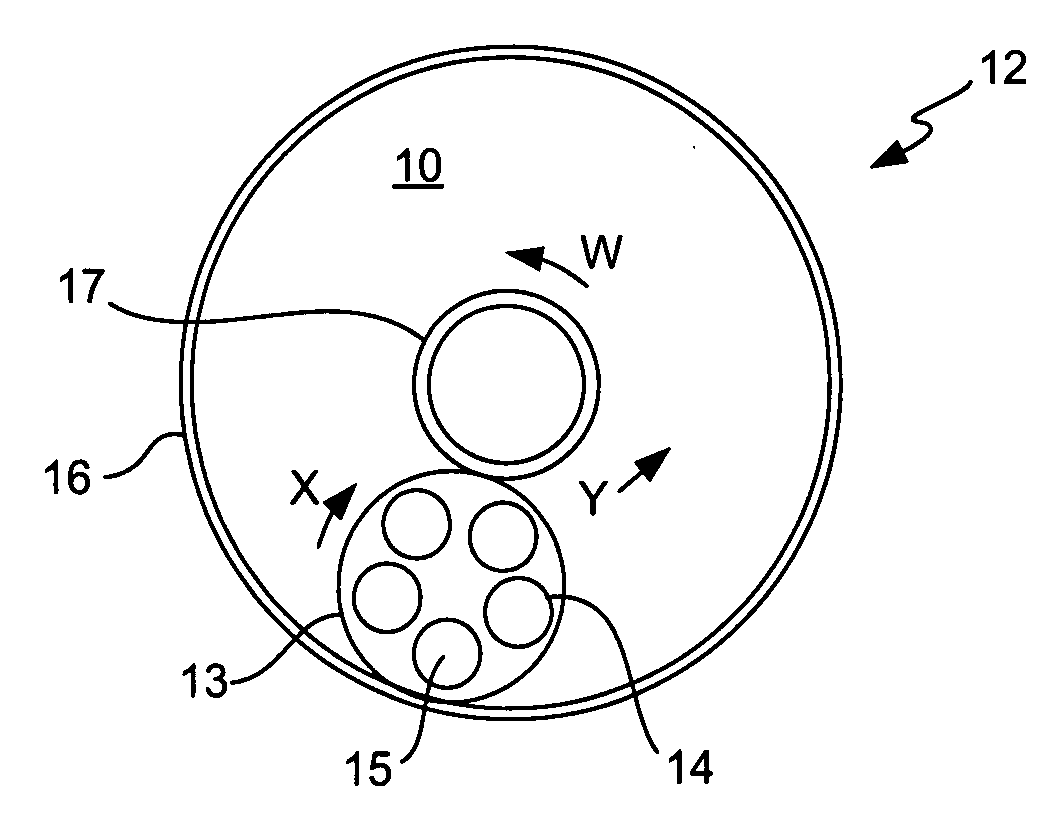

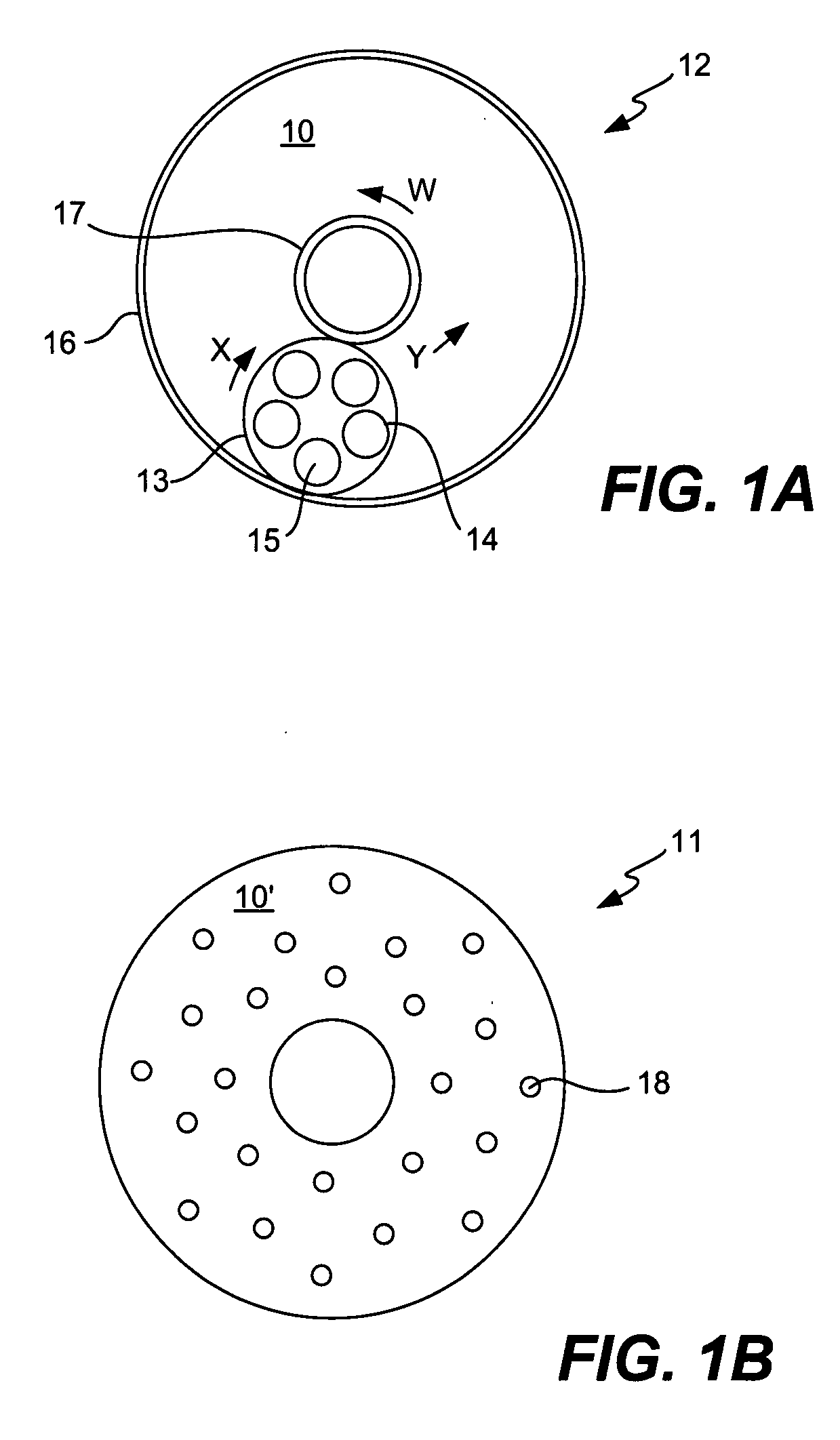

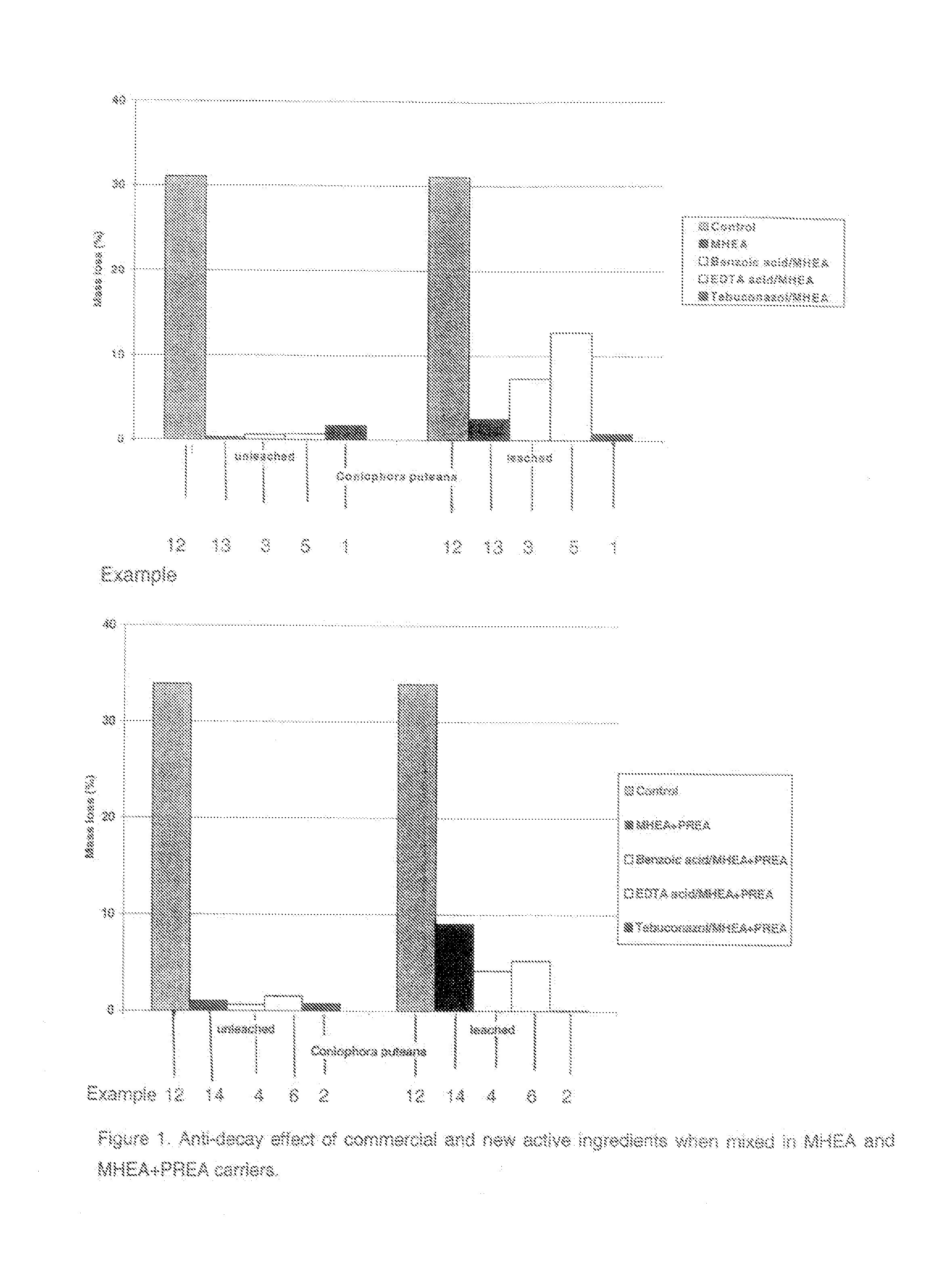

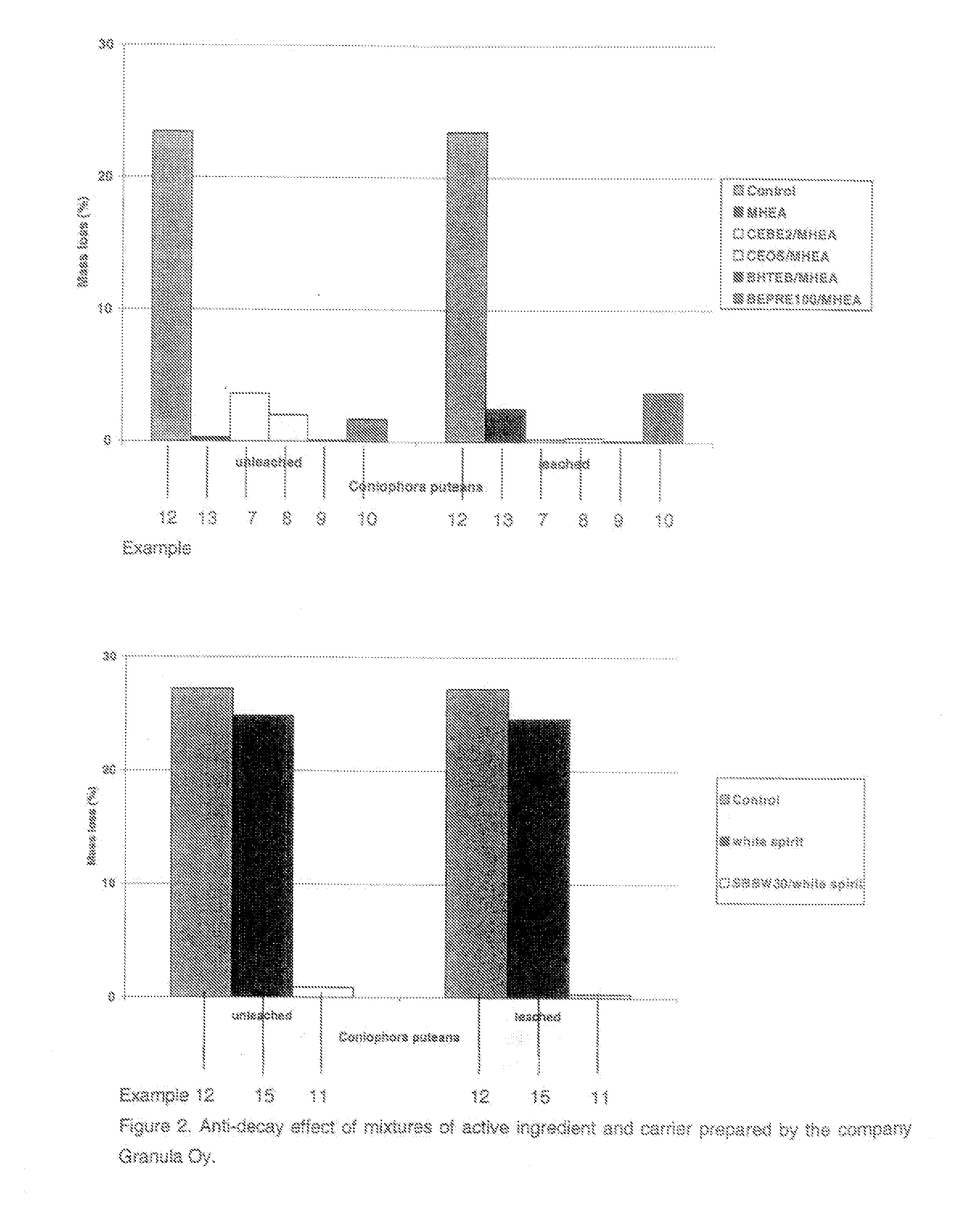

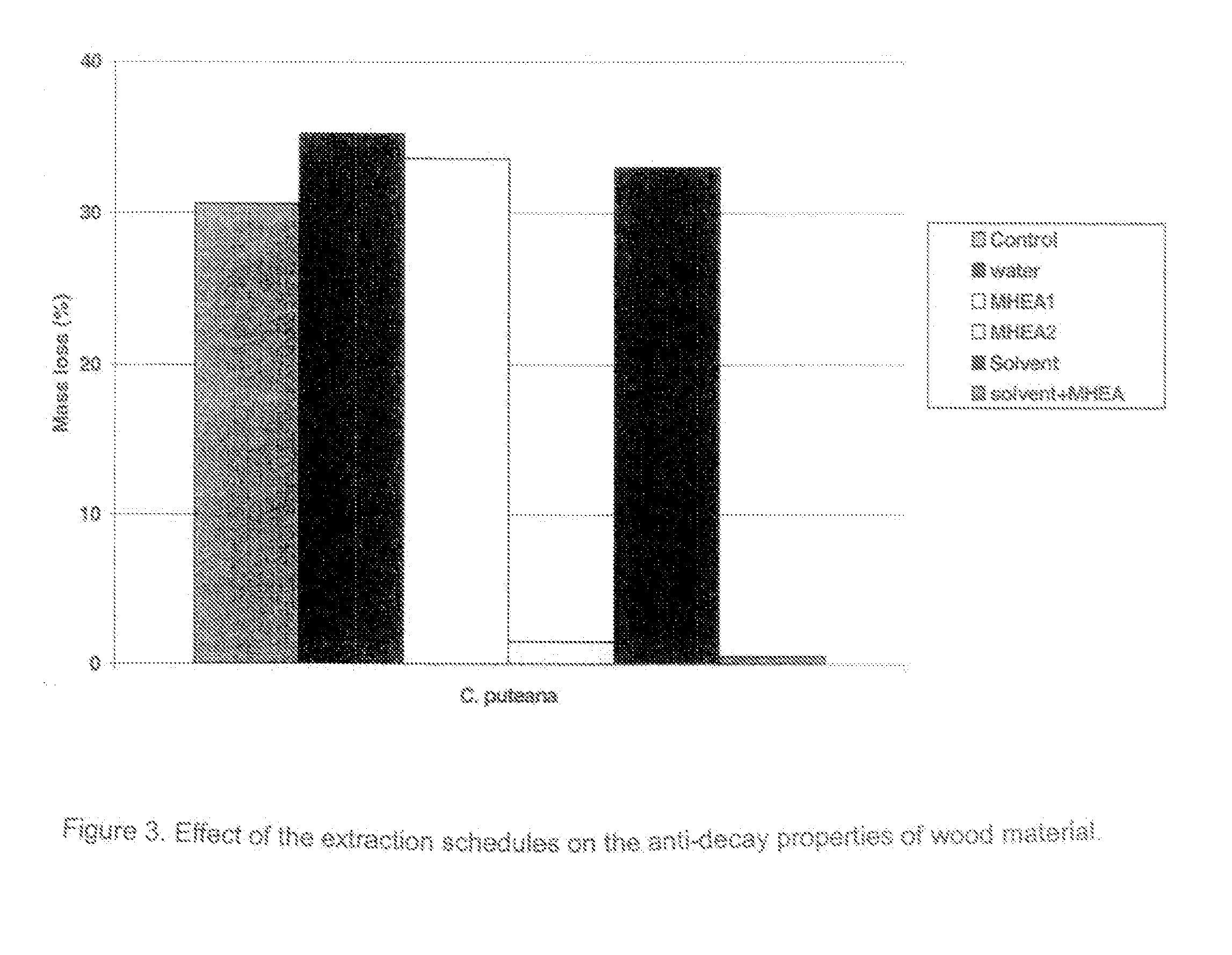

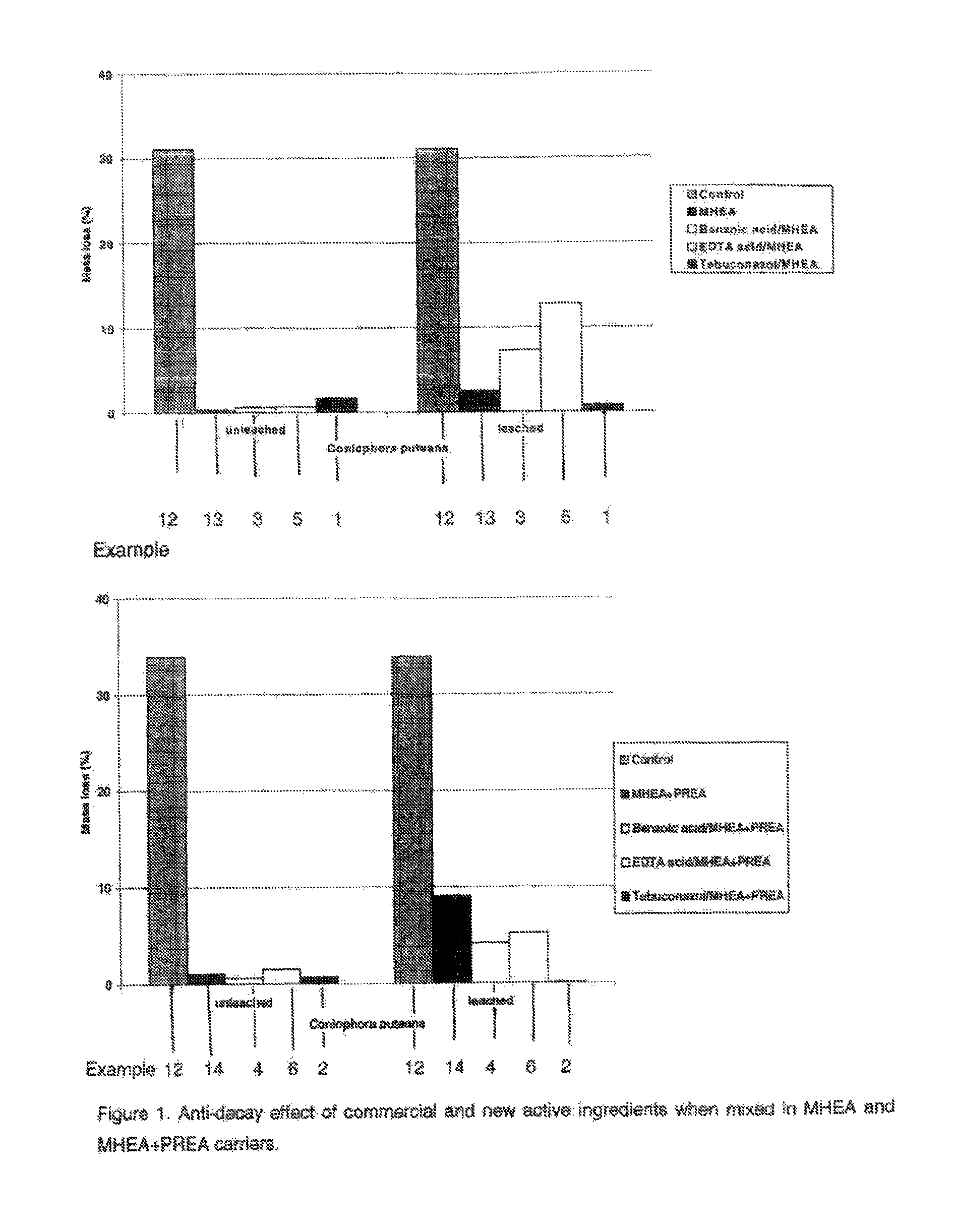

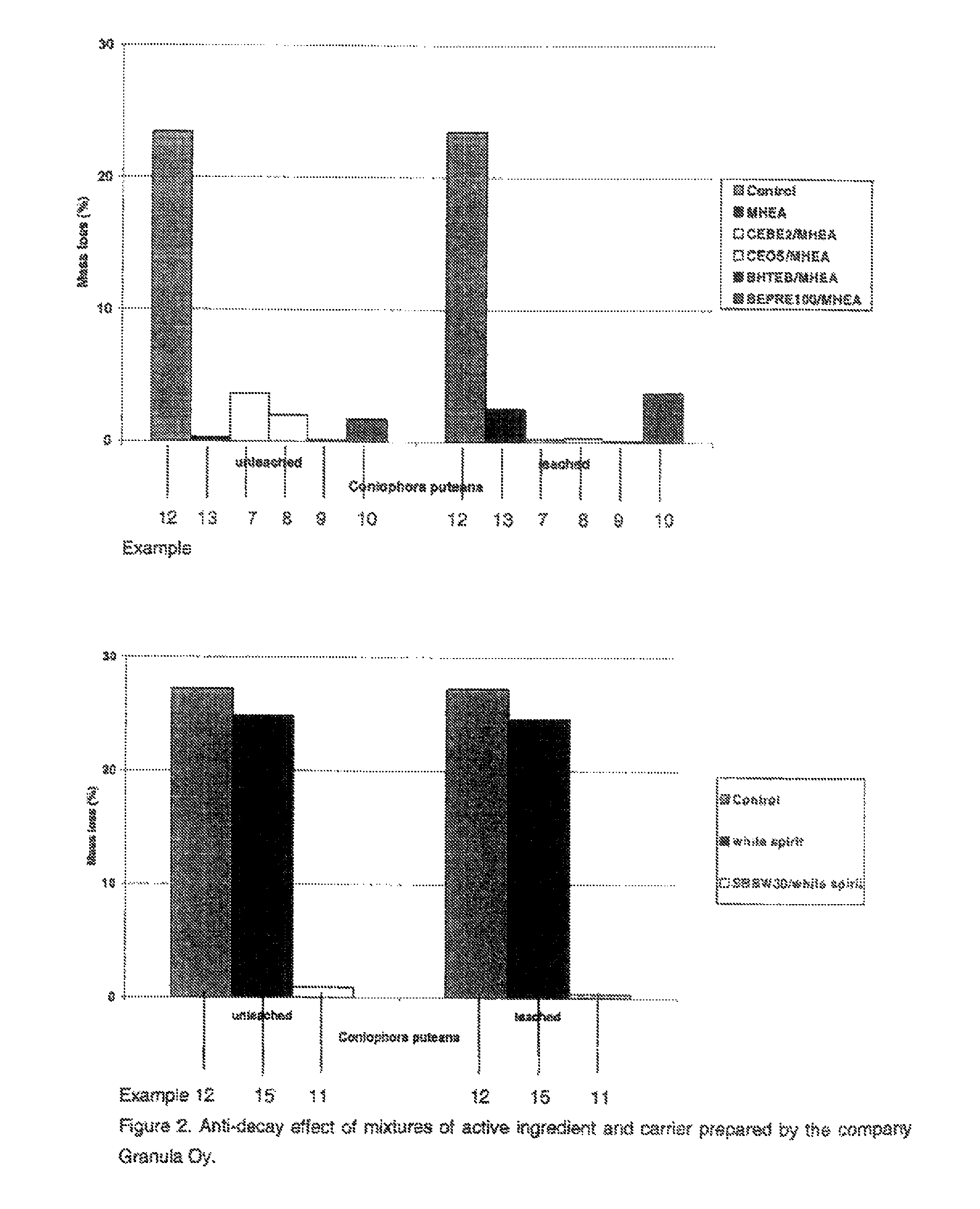

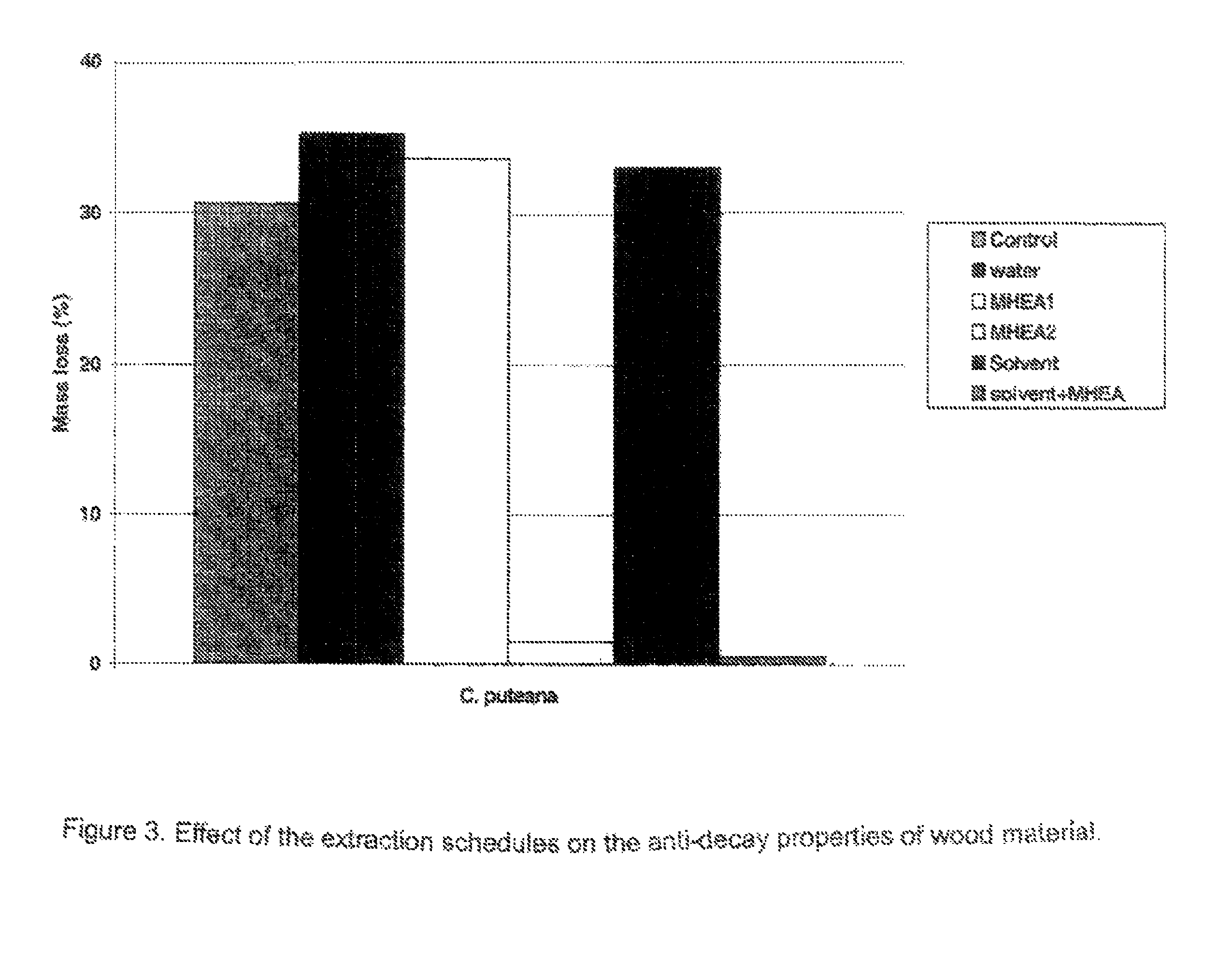

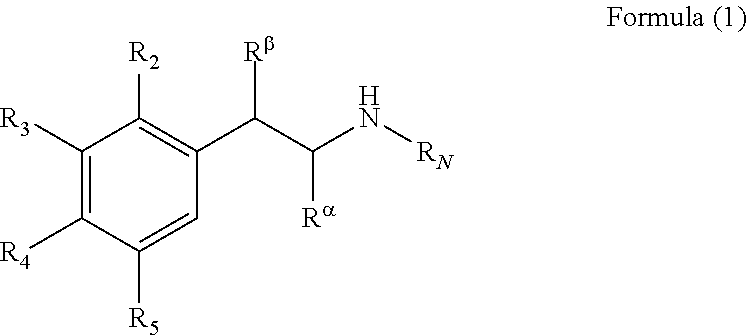

Method for treating wood

ActiveUS20110088590A1Promote absorptionEasy to keepFireproof paintsBiocideMethylating AgentCarboxylic salt

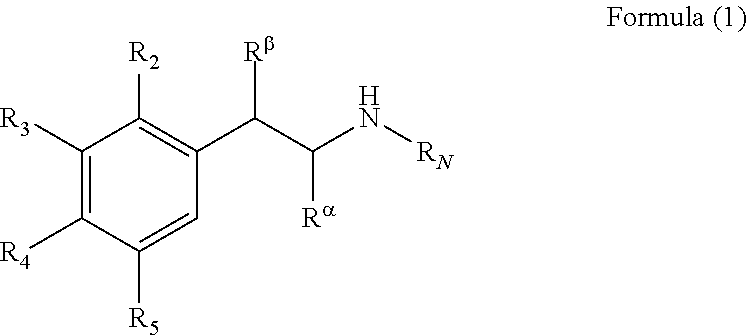

Described is a method for treating wood, in which the wood is brought into contact with a mixture of liquid or water-soluble organic ammonium carboxylate and an active ingredient which repels invertebrates, characterized in that the organic ammonium carboxylate has the formula (1):[NR1R2R3R4]+n[R5(COO)n]−n (1),in which R1, R2 and R3 are selected from hydrogen, substituted and unsubstituted alkyls containing 1-6 carbon atoms, R4 is a substituted or unsubstituted alkyl containing 1-6 carbon atoms, R5 is hydrogen, a substituted or unsubstituted hydrocarbon containing 1-6 carbon atoms and n is an integral 1-6 and whereby wood-preservative active ingredient contains a chelating agent which repels invertebrate, which chelating agent is selected from an aminopolycarboxylic acid or a salt thereof, a hydroxy acid or a salt thereof or a phosphonate or a salt thereof or a mixture of chelating agents which belong to two of more groups thereof.

Owner:GRANULA

Method of polishing nickel-phosphorous

ActiveUS20100009537A1Other chemical processesDecorative surface effectsCarboxylic acidSilicon dioxide

The invention is directed to a method of chemically-mechanically polishing a a surface of a substrate, comprising contacting a surface of a substrate comprising nickel-phosphorous with a chemical-mechanical polishing composition comprising wet-process silica, an agent that oxidizes nickel-phosphorous, and an aminopolycarboxylic acid, wherein the polishing composition has a pH of about 1 to about 5, and abrading at least a portion of the nickel-phosphorous to polish the substrate.

Owner:CMC MATERIALS INC

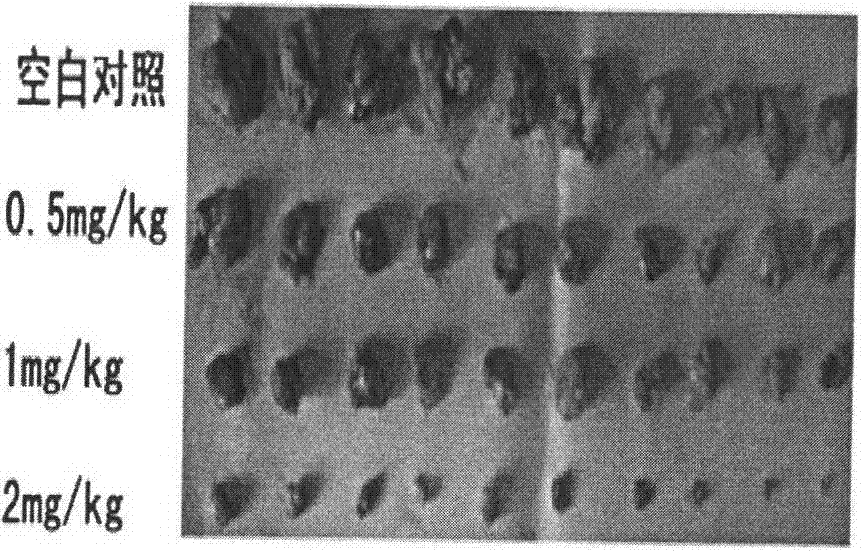

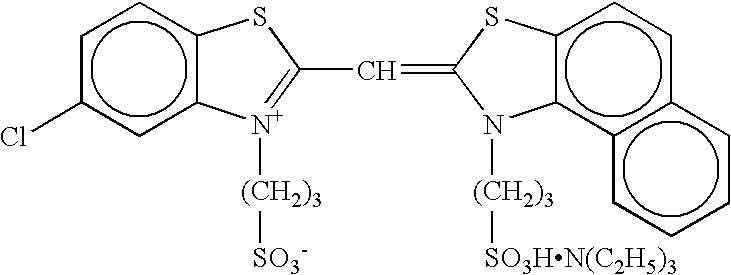

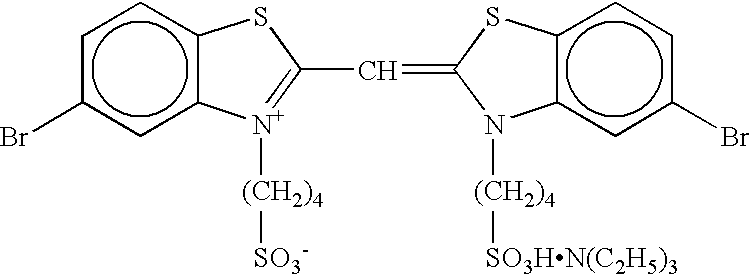

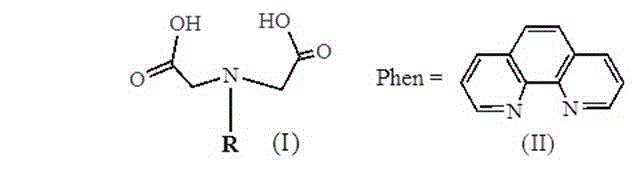

Preparation method and application of water-soluble aminopolycarboxylic acid modified phthalocyanine compound

ActiveCN103539799AHigh fluorescence quantum yieldImprove stabilityOrganic chemistryEnergy modified materialsSodium bicarbonateFluorescence

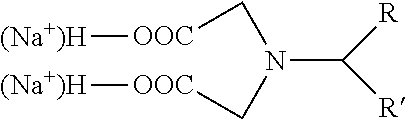

The invention discloses a water-soluble aminopolycarboxylic acid modified phthalocyanine compound as well as a preparation method and an application thereof. The water-soluble aminopolycarboxylic acid modified phthalocyanine compound is characterized in that the side chain or the center is connected to aminopolycarboxylic acid, the aminopolycarboxylic acid connected to the side chain is as shown in a structure (I) in the description, and the aminopolycarboxylic acid connected to the center is as shown in a structure (II) in the description. The preparation method of the water-soluble aminopolycarboxylic acid modified phthalocyanine compound is simple and easy to operate. After the phthalocyanines compound is modified by the method, the phthalocyanine compound has stable chemical property and can be completely dissolved in a sodium bicarbonate aqueous solution, the degree of self aggregation of phthalocyanine is reduced, and the phthalocyanine compound is absorbed in a 600-900 nm near-infrared zone and can be applied to the fields of near infrared fluorescence imaging or photodynamic tumor treatment.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

Composition for treating surface of metal, method for treating surface of metal using the composition, and coating film for treating surface of metal utilizing the composition and the method

InactiveUS20110311838A1Improve not only the catalysis ability for curing a resinElectrophoretic coatingsThin material handlingWater basedMetallic materials

A composition for metal surface treatment capable of forming films and imparting excellent corrosion resistance in relation to metallic materials, in particular, metal formations having complex shapes through a single dipping step. A composition for metal surface treatment contains 5 to 30% by weight of a nonionic and / or cationic water-based resin, 100 to 1,000 ppm of trivalent Bi ions and an aminopolycarboxylic acid at 0.5 to 10 times in molar concentration based on the Bi ions.

Owner:NIHON PARKERIZING

Preparation process for diethylene triaminepentaacetic acid dianhydride modified polyvinylidene fluoride separation membrane and resin

InactiveCN101961605AUniform removalImprove hydrophilicitySemi-permeable membranesIndustrial waste waterSolvent

The invention provides a preparation process for a diethylene triaminepentaacetic acid dianhydride modified polyvinylidene fluoride separation membrane and a resin with solvents of diethylene triaminepentaacetic acid dianhydride, sodium hydroxide, sodium borohydride, tetrabutyl ammonium bromide, p-toluenesulfonic acid, N,N-dimethylacetylamide, polyvinylpyrrolidone and the like as raw materials by utilizing a chemical blending / phase transfer process, which has the advantages of simple operation, uniform blending and the like. In the process, diethylene triaminepentaacetic acid multi-aminopolycarboxylic acid compounds are uniformly blended in the polyvinylidene fluoride separation membrane and the resin; the hydrophilic performance of the polyvinylidene fluoride separation membrane and the resin is improved; the elimination of complexing state heavy metal ions from waste water can be realized by utilizing the polyvinylidene fluoride separation membrane and the resin; the efficiency for purifying drinking water by utilizing the polyvinylidene fluoride separation membrane and the resin is enhanced; the elimination and the recycling utilization of the complexing state heavy metal ions in industrial waste water can be promoted; and the application of the polyvinylidene fluoride separation membrane and the resin in the field of water processing is expanded.

Owner:YANSHAN UNIV

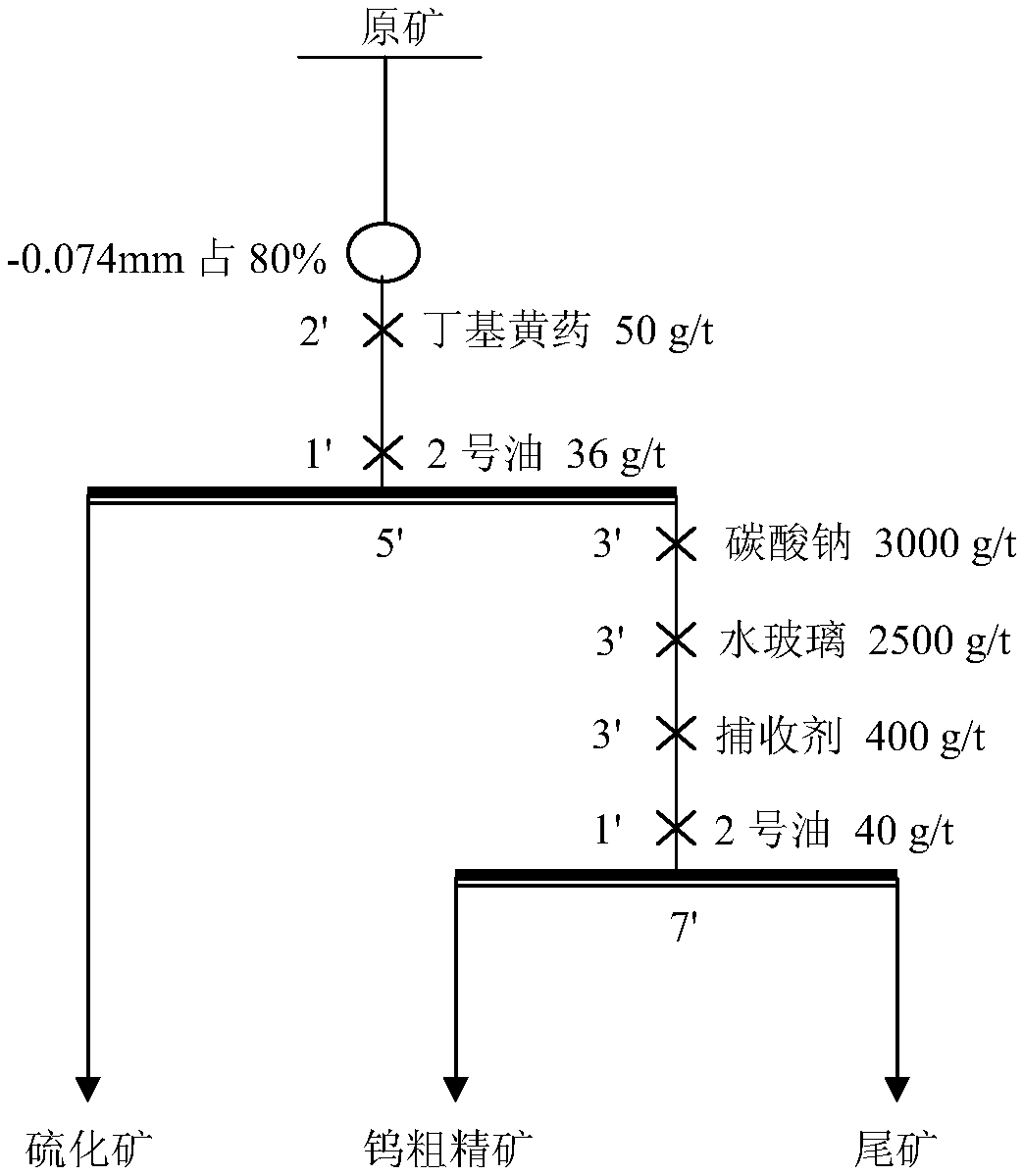

Application of acyl amino polycarboxylic acid/hydroximic acid like compound in mineral flotation

ActiveCN109499773AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

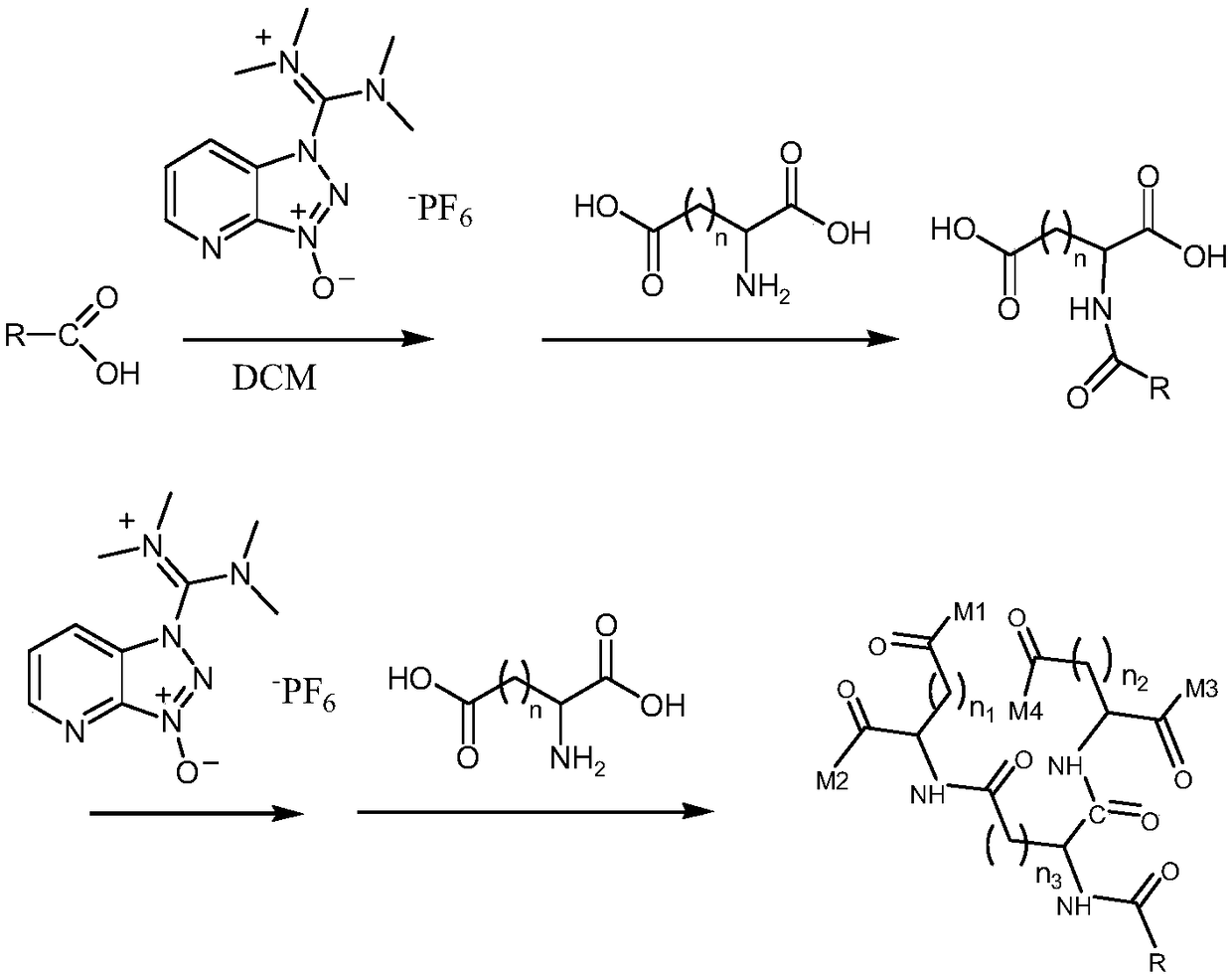

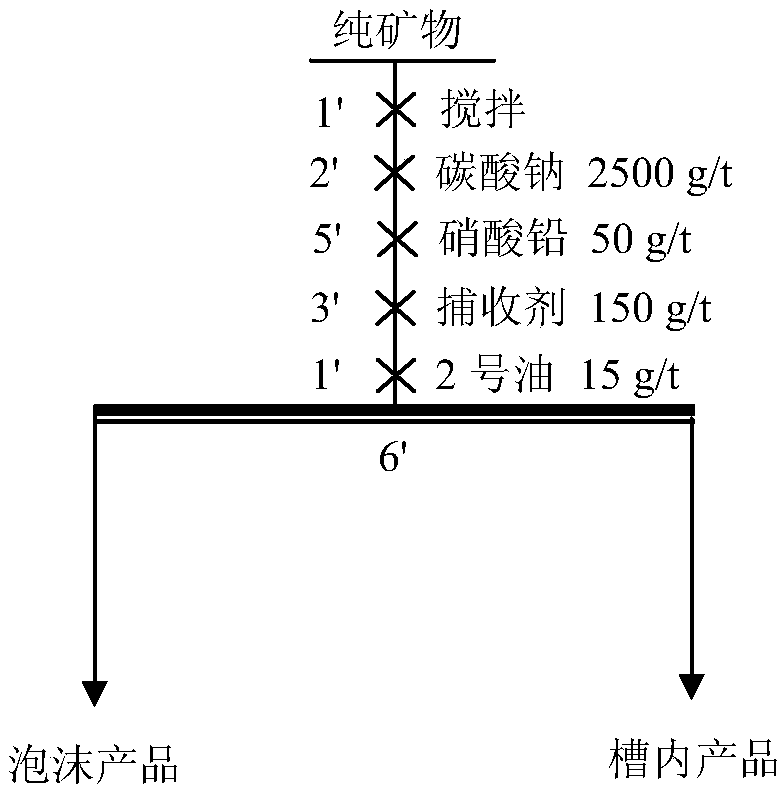

The invention provides application of acyl amino polycarboxylic acid / hydroximic acid like compound in mineral flotation. A structural formula of the acyl amino polycarboxylic acid / hydroximic acid likecompound is shown as a formula (I); (shown in the description) wherein R in the formula (I) represents aliphatic hydrocarbyl of C<6>-C<18>, n=1-3, and M1, M2, M3 and M4 are separately selected from one or several of -OH, -ON, -OK, -NHOH, -NHON or -NHOK. And n<1>=1-3, n<2>=1-3, and n<3>=1-3. The acyl amino polycarboxylic acid / hydroximic acid like compound is used as a collecting agent to enhance the chelation and recognition action on metal oxidized ores, facilitate ordered arrangement of the collecting agent on the mineral surface, effective flotation recovery is carried out on tungstenores, rare earth ores, tin ores, lithium ores, phosphorus ores, manganese oxide ores, cooper oxide ores, fluorites or titanium iron ores, the acyl amino polycarboxylic acid / hydroximic acid collectingagent has the advantages of high collecting capacity, high selectivity, low ton ore use amounts and the like, and is especially suitable for processing difficultly selected fine grain ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

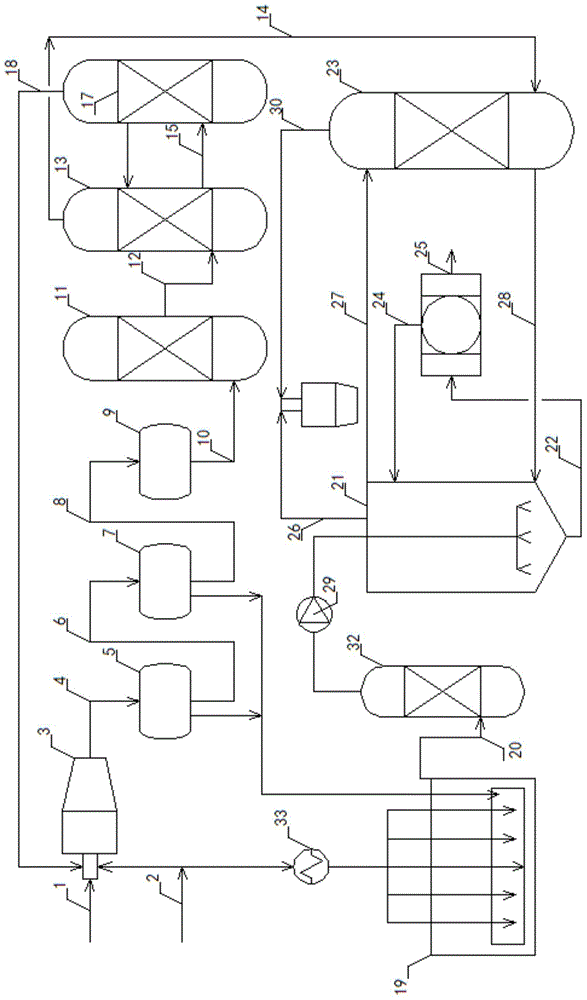

System and method for reducing sulfur dioxide emission concentration of sulfur recovery device and desulfurization agent

InactiveCN104787730ALow concentration of sulfur dioxideLess investmentDispersed particle separationSulfur preparation/purificationFlue gasSulfur

The invention belongs to the technical field of sulfur recovery and particularly relates to a system and a method for reducing sulfur dioxide emission concentration of a sulfur recovery device and a desulfurization agent. The desulfurization agent comprises aminopolycarboxylic acid chelate iron, an aminopolycarboxylic acid chelating agent, acrylamide and fatty alcohol polyoxyethylene ether-9 and water. The system comprises a complex iron desulfurization device, the sulfur recovery device and a liquid sulfur tank gas stripping device; tail gas generated by degassing of a liquid sulfur tank and the sulfur recovery device is purified in a complex iron desulfurization system, so that various factors causing sulfur dioxide emission of the sulfur recovery device are radically eliminated from the source; the sulfur dioxide concentration of flue gas after incineration is guaranteed to be lower than 50 mg / Nm<3>; thermal reaction and conversion parts of an existing sulfur recovery device are not changed, so that the investment is low and the running cost is low; air is utilized for degassing of the liquid sulfur tank and serves as regeneration air of the complex iron desulfurization system, so that the running cost of liquid sulfur degassing purification is reduced; a comprehensive and complete solution is provided for reducing the sulfur dioxide emission concentration of the sulfur recovery device.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Foamed chelating agent treatment fluids for use in subterranean matrix stimulations and subterranean and surface cleanout operations

ActiveUS10005955B2Less corrosivePrevent redepositionFluid removalDrilling compositionFoaming agentEarth surface

Treatment fluids and methods include a method that includes the steps of providing or preparing a foamed chelating agent treatment fluid that includes: an aminopolycarboxylic acid chelating agent, an aqueous base fluid, a gas, and a foaming agent, and lacing the foamed chelating agent treatment fluid in a subterranean formation penetrated by a well bore. The aminopolycarboxylic acid chelating agent foamed fluids may also be used in equipment clean-out operations.

Owner:HALLIBURTON ENERGY SERVICES INC

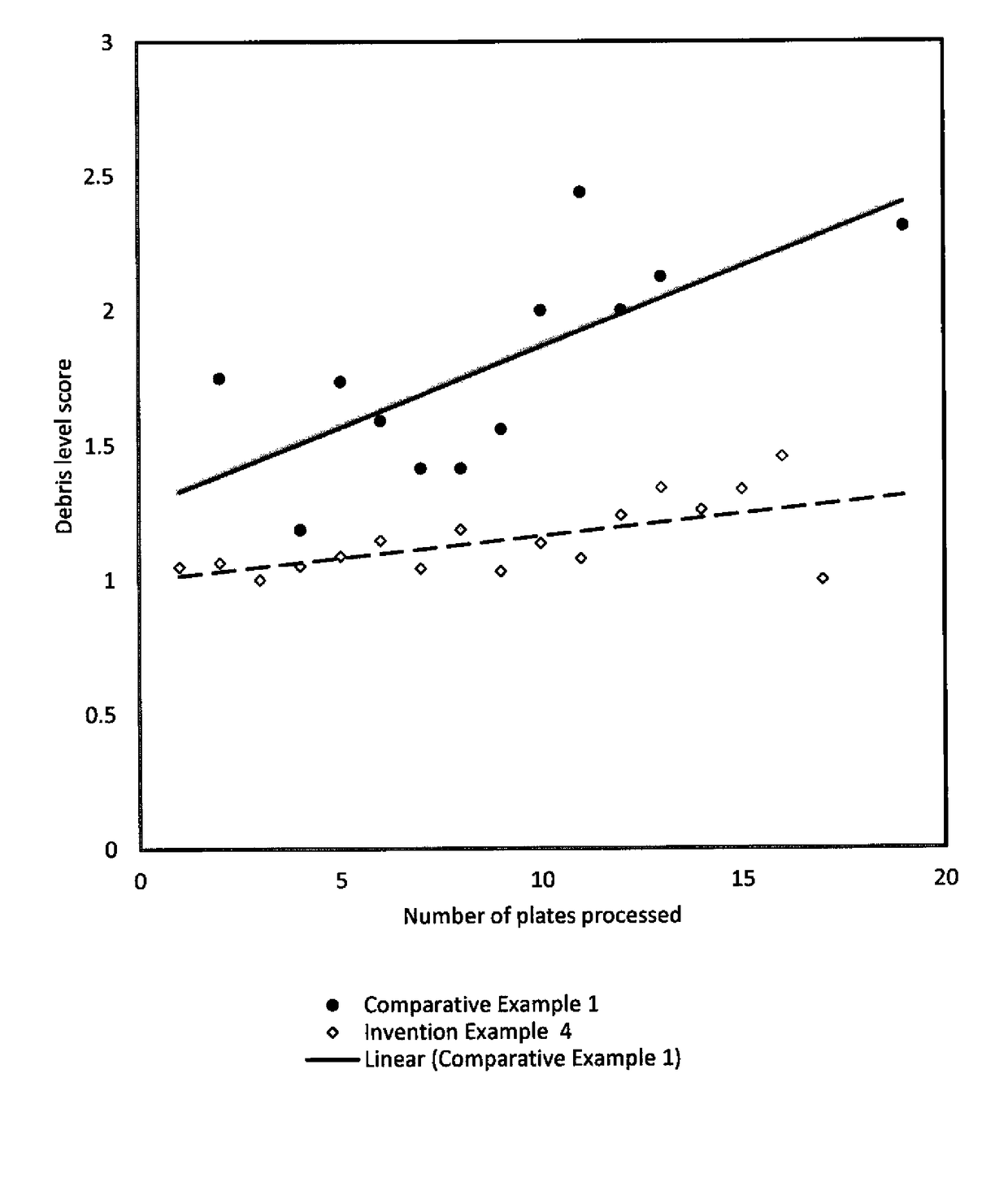

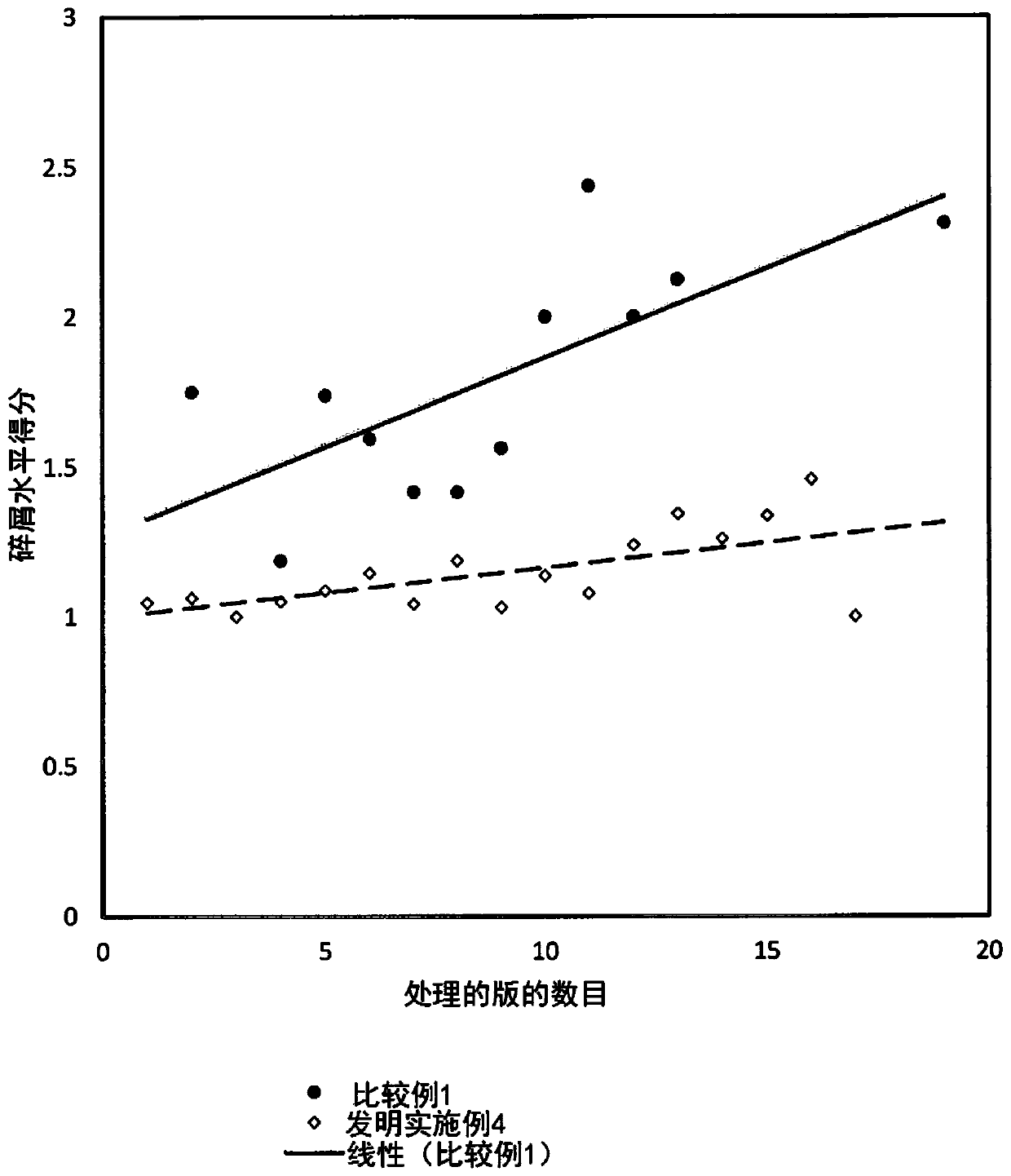

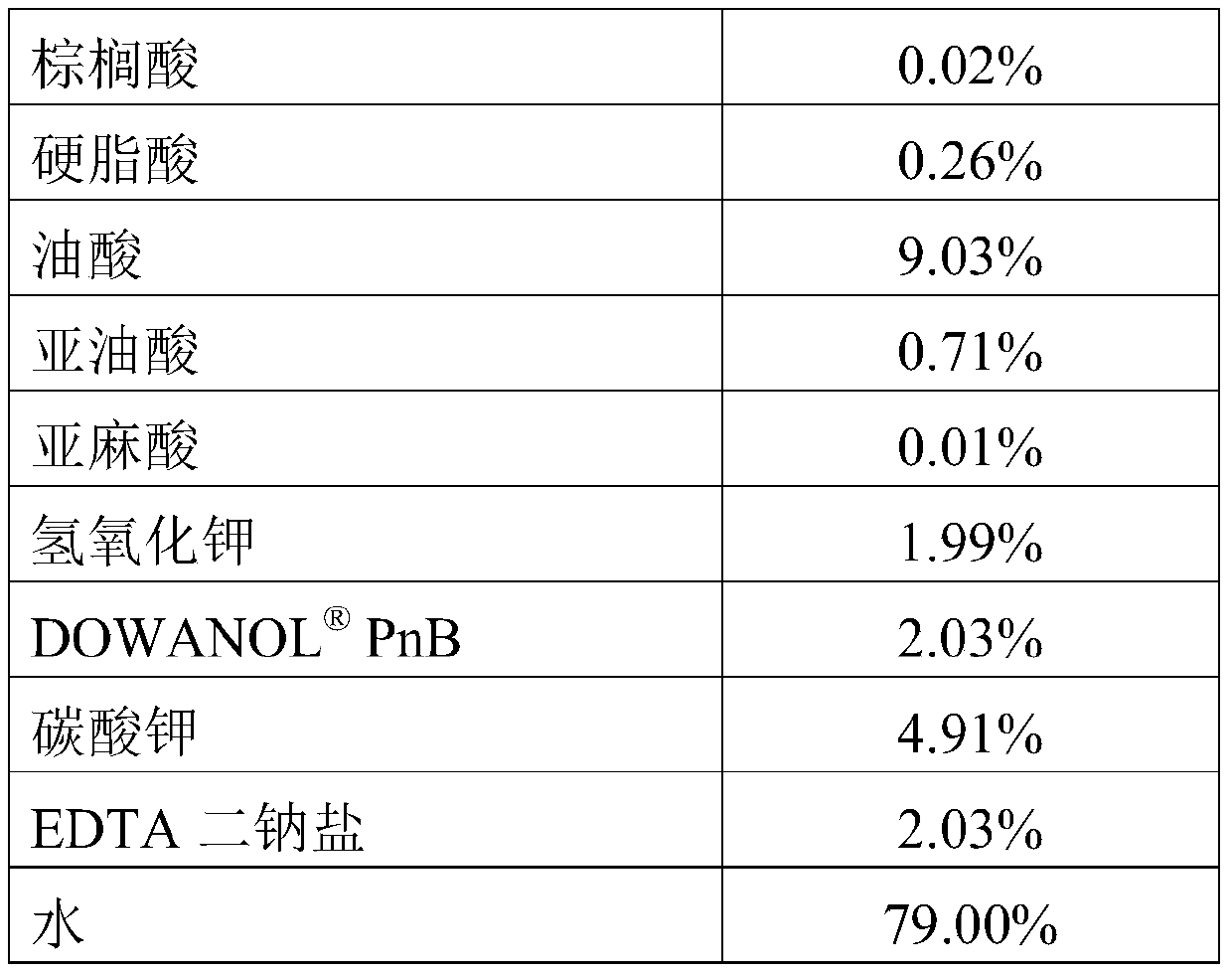

Concentrated and working strength aqueous flexographic developers

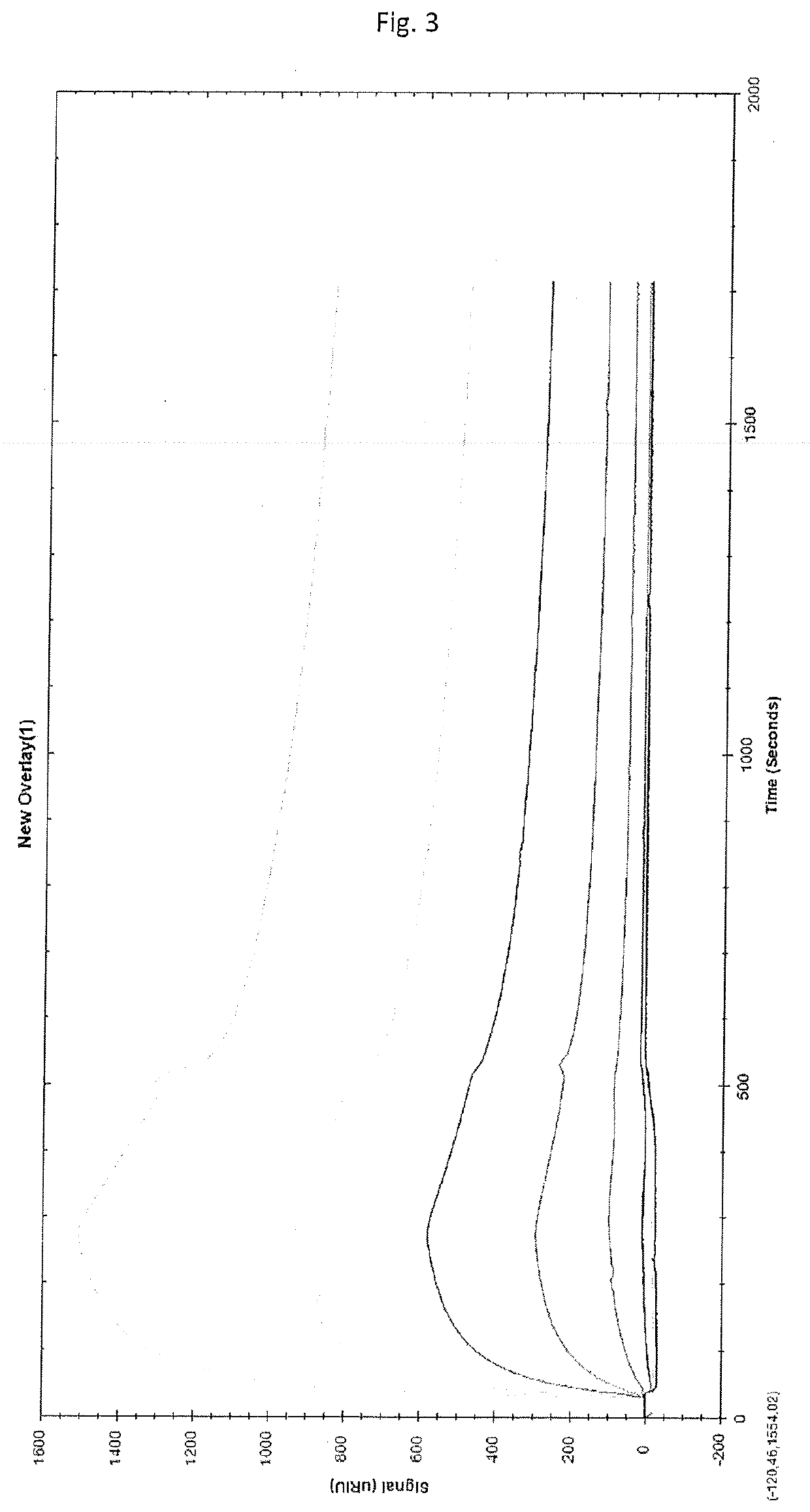

ActiveUS20180136561A1Composition is stableReduce the amount requiredPhotomechanical exposure apparatusPhotosensitive material processingUltimate tensile strengthNuclear chemistry

Flexographic printing members are prepared by developing an exposed flexographic printing member precursor with an aqueous flexographic developer. The aqueous flexographic developer comprises: a) a fatty acid composition consisting of one or more saturated or unsaturated fatty acids or alkali metal salts thereof, each saturated or unsaturated fatty acid or alkali metal salt thereof independently having 12 to 20 carbon atoms, the fatty acid composition being present in an amount of 0.25-2.0 weight %, and at least 85 weight % of the fatty acid composition is composed of one or more C18 mono- or poly-unsaturated fatty acids or alkali metal salts thereof; b) an aminopolycarboxylic acid or alkali metal salt thereof in an amount of 0.05-0.30 weight %; c) a buffer compound in an amount of 05-0.60 weight %; and d) water. Such aqueous flexographic developers can also be provided in concentrated form and appropriately diluted before or during use.

Owner:MIRACLON CORP

Method for treating wood

ActiveUS8361210B2Promote absorptionEasy to keepFireproof paintsBiocideMethylating AgentCarboxylic salt

Described is a method for treating wood, in which the wood is brought into contact with a mixture of liquid or water-soluble organic ammonium carboxylate and an active ingredient which repels invertebrates, characterized in that the organic ammonium carboxylate has the formula (1):[NR1R2R3R4]+n[R5(COO)n]−n (1),in which R1, R2 and R3 are selected from hydrogen, substituted and unsubstituted alkyls containing 1-6 carbon atoms, R4 is a substituted or unsubstituted alkyl containing 1-6 carbon atoms, R5 is hydrogen, a substituted or unsubstituted hydrocarbon containing 1-6 carbon atoms and n is an integral 1-6 and whereby wood-preservative active ingredient contains a chelating agent which repels invertebrate, which chelating agent is selected from an aminopolycarboxylic acid or a salt thereof, a hydroxy acid or a salt thereof or a phosphonate or a salt thereof or a mixture of chelating agents which belong to two of more groups thereof.

Owner:GRANULA

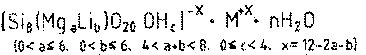

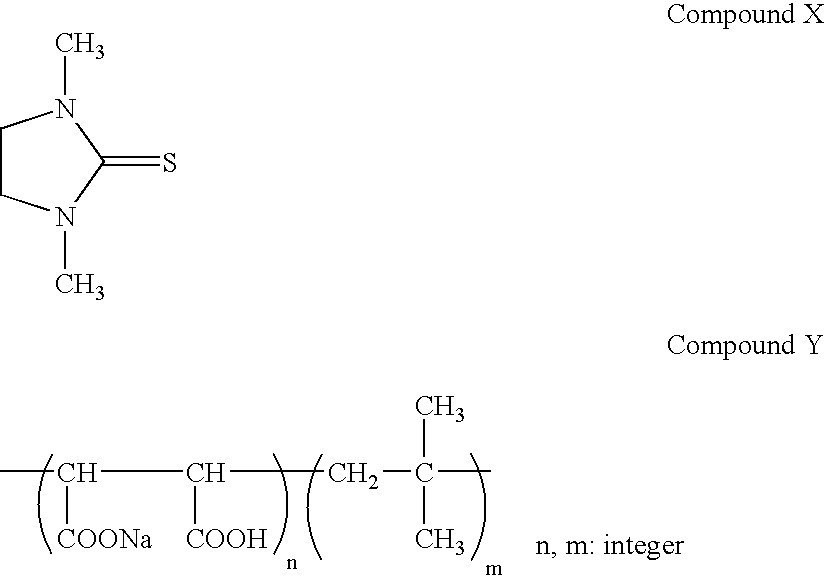

Thixotropic agent and method for producing same

InactiveCN103547650AImprove thixotropyReduce contentCosmetic preparationsMake-upClay mineralsAlkaline earth metal

[Problem] To provide a thixotropic agent having excellent thixotropic properties. [Solution] A thixotropic agent contains a clay mineral compound formed from a phyllosilicate mineral having between layers at least one of an alkali metal ion and alkaline earth metal ion as the interlayer metal ion. A metal complex compound obtaining by bonding an aminopolycarboxylate or a derivative of the aminopolycarboxylate to the interlayer metal ion is, as the active species, introduced between the layers of the phyllosilicate mineral to produce the clay mineral compound.

Owner:YAMAGUCHI MICA

Concentrated composition of blix solution for silver halide color photographic photosensitive material

InactiveUS20040023167A1Reduce the amount requiredShorten the timeMulticolor photographic processingOriginals for photomechanical treatmentBleachCarboxylic acid

A concentrated blix solution composition, which can remarkably reduce the replenishing amount of the blix solution and / or remarkably reduce the blix time, comprises: 1) a concentrated composition part containing a bleaching agent; and 2) a concentrated composition part containing a fixing agent, wherein the part concentrated composition 1) satisfies all the following conditions: (1) pH is from 2.0 to 3.5, (2) a specific gravity is 1.130 or more, (3) the bleaching agent comprises an iron(III) complex salt of an aminopolycarboxylic acid, (4) a concentration of the bleaching agent is from 0.5 to 1.0 mole / L, and (5) a content of an aminopolycarboxylic acid having not been complexed is from 0.1 to 3% by mole based on the bleaching agent, and a processing process using the same.

Owner:FUJIFILM CORP

Method of polishing nickel-phosphorous

The invention is directed to a method of chemically-mechanically polishing a surface of a substrate, comprising contacting a surface of a substrate comprising nickel-phosphorous with a chemical-mechanical polishing composition comprising wet-process silica, an agent that oxidizes nickel-phosphorous, and an aminopolycarboxylic acid, wherein the polishing composition has a pH of about 1 to about 5, and abrading at least a portion of the nickel-phosphorous to polish the substrate.

Owner:CMC MATERIALS LLC

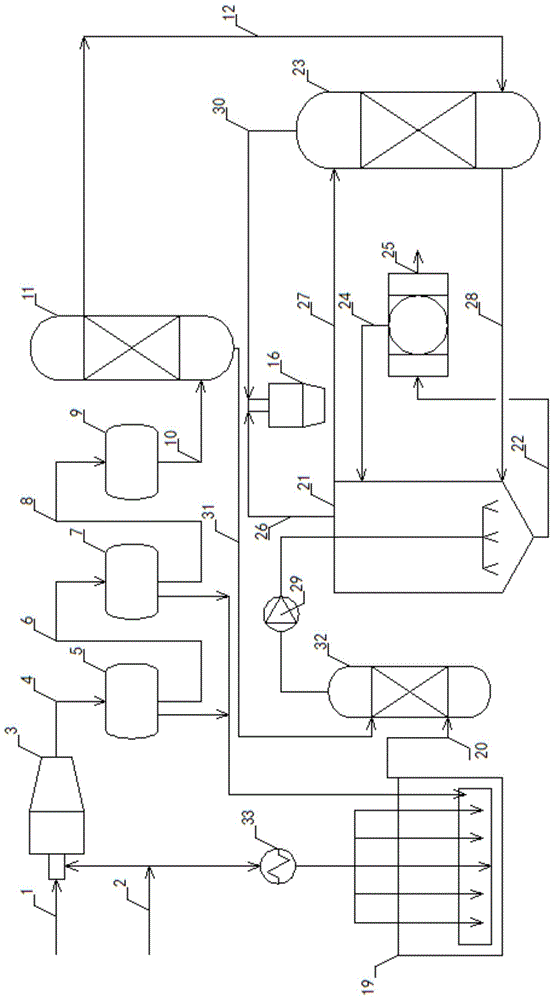

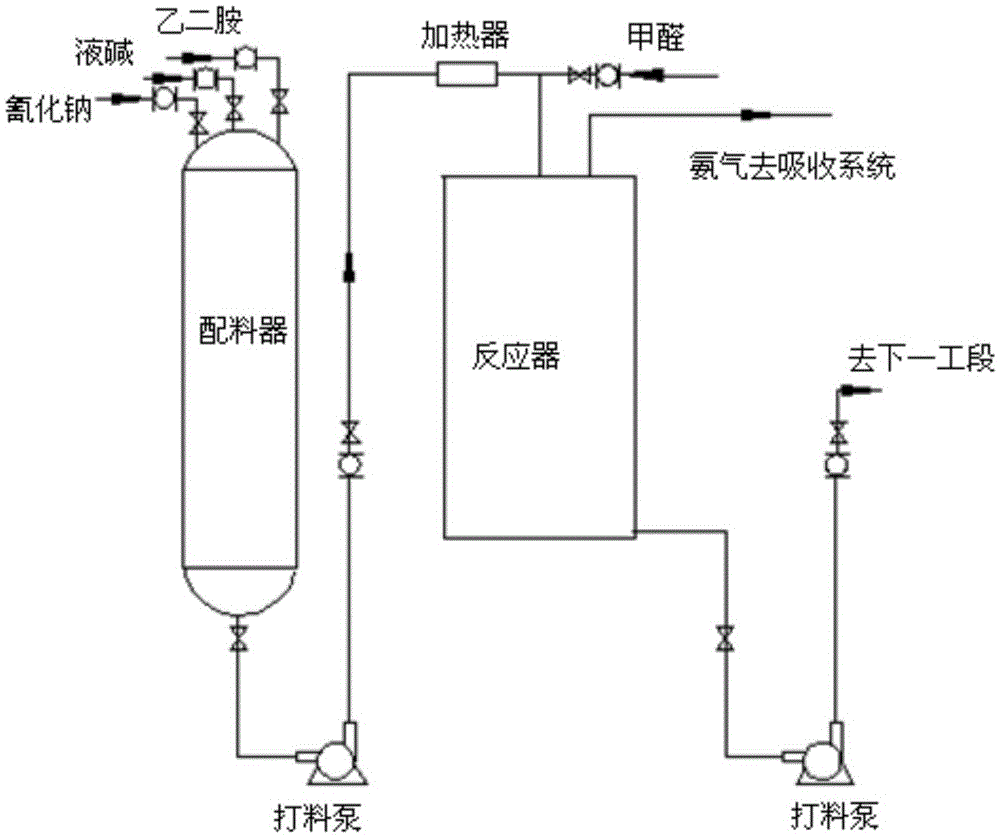

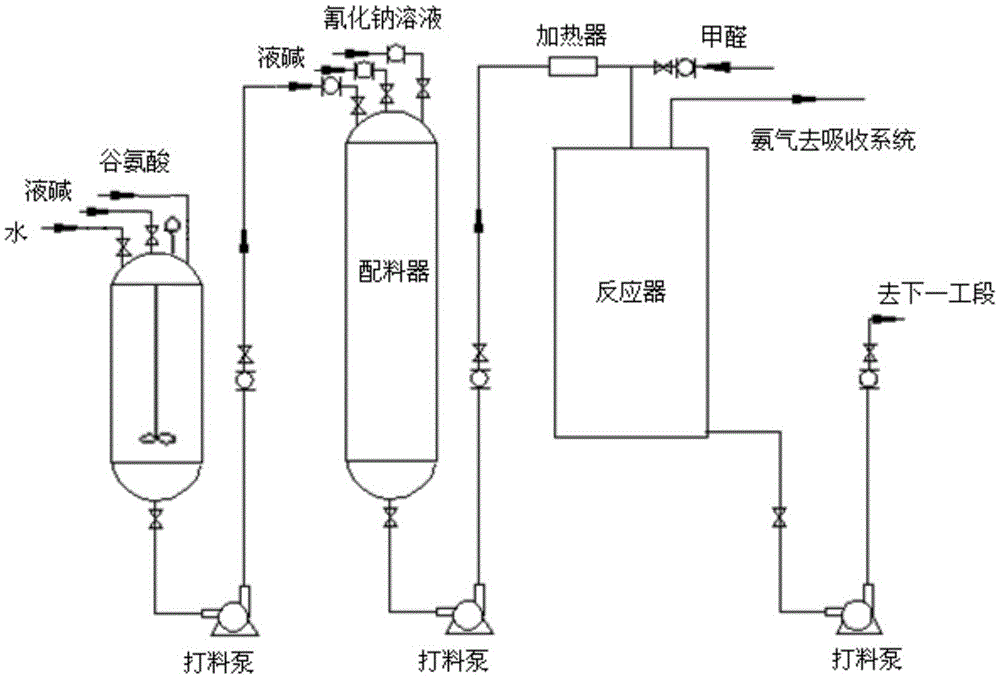

Novel continuous automated reaction process for preparing aminopolycarboxylic acids chelating agent

ActiveCN105646254AImprove qualityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationContinuous reactorAfter treatment

The invention discloses a novel continuous automated reaction process for preparing an aminopolycarboxylic acids chelating agent and belongs to the technical field of aminopolycarboxylic acids chelating agents. Production is conducted through a flow reactor, a whole reaction system is under DCS automation control, and the process comprises the following steps: 1, material blending and mixing, wherein raw materials are continuously and stably pumped into a batcher for mixing, so that a liquid mixture is obtained; 2, preheating treatment, wherein the liquid mixture is pumped out of the batcher through a material delivering pump, and the liquid mixture which is pump out is subjected to heating treatment through a heater; 3, reaction and generation, wherein heated liquid materials and formaldehyde or heated liquid materials and a glycolonitrile solution are added into the reactor for a reaction, ammonia gas generated through the reaction is discharged through the top of the reactor and collected, and a reaction solution is drained through the bottom of the reactor and delivered to the acidification procedure for after-treatment through the material delivering pump, so that the aminopolycarboxylic acids chelating agent is obtained. By means of the process, the aminopolycarboxylic acids chelating agent can be produced in a continuous and automated mode, and stability of the reaction process is improved.

Owner:石家庄杰克化工有限公司

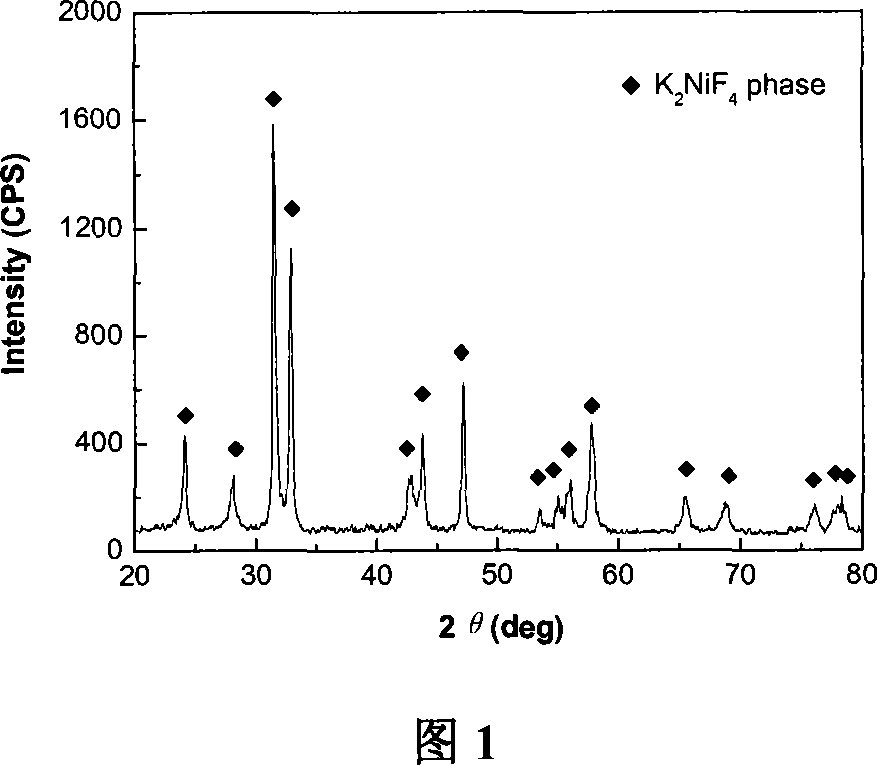

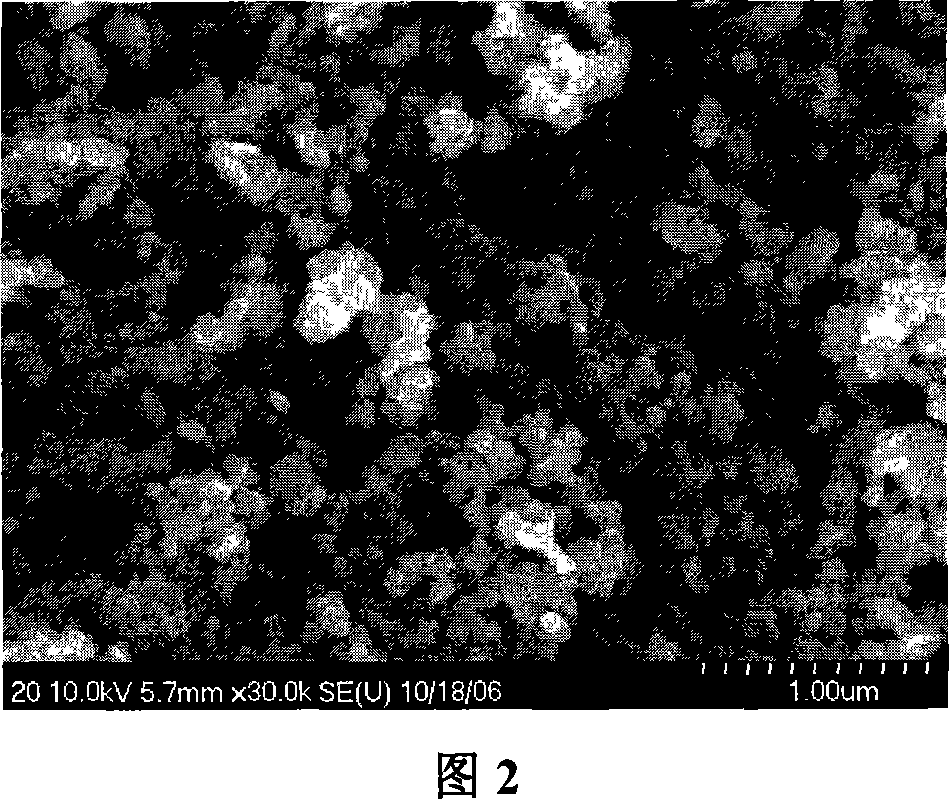

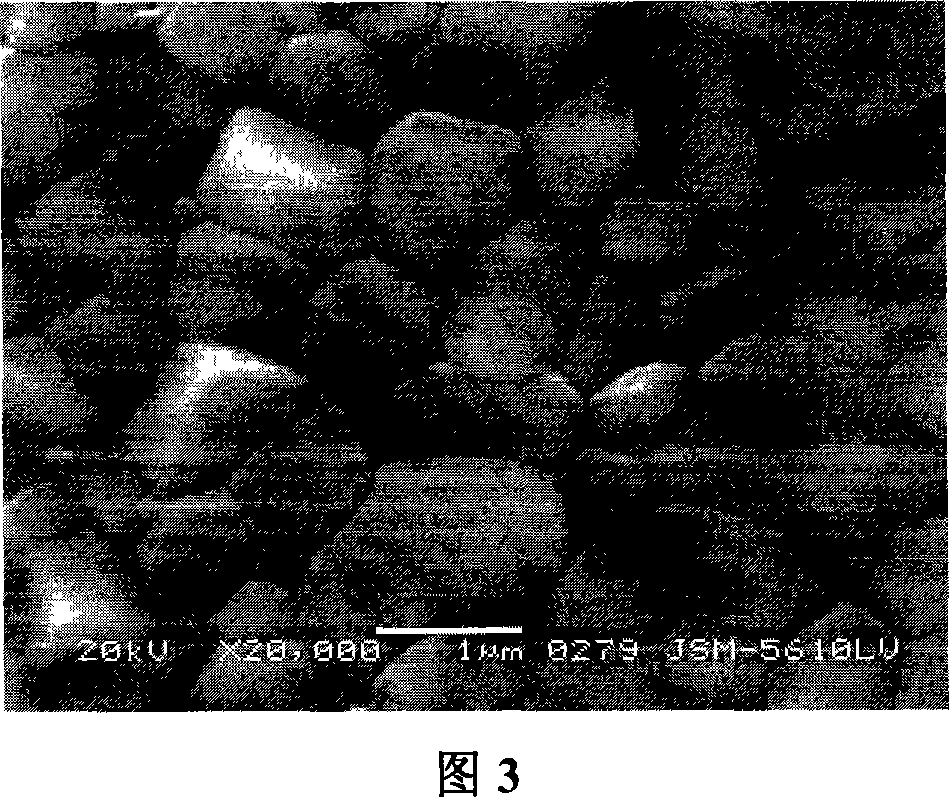

Method for synthesizing electron-ion mixed conductor material

InactiveCN101054196AHigh phase puritySmall particlesCobalt oxides/hydroxidesElectrical conductorDiethylenetriamine

The present invention relates to a method for synthesizing a electron-ion mixed conducting material with a K2NiF4 structure of the La2-xSrxNi1-yMeyo4+delta system. The carbonate or hydroxide of various component elements is mixed with diethylenetriamine pentaacetic acid in deionized water according to the stoichiometric ratio of synthetic product, the mixture is heated and agitated so that the carbonate or hydroxide is dissolved completely to form clarifying and transparent solution of precursor, and then the transparent glass state aminopolycarboxylic acid complexes precursor is obtained by means of heating and drying; finally, the complexes precursor is heated to create the ultramicro composite powder with single K2NiF4 structure. The present invention has a simple synthesizing technology, a low synthesizing temperature, a short synthesizing time, a controllable synthesizing process, and an excellent repeatability. The synthetic product has a high phase purity, fine and uniform particles, and can be widely used as the cathode of moderate temperature solid oxide fuel battery, and used for the electrochemical sensor and the oxygen separation membrane, and has a broad application prospect.

Owner:WUHAN UNIV OF TECH

Cleaning composition and cleaning method using the same

ActiveUS20140107008A1Improve wetting abilityGood cleaning efficiencyNon-surface-active detergent compositionsDetergent mixture composition preparationEnvironmental engineeringCarboxylic acid

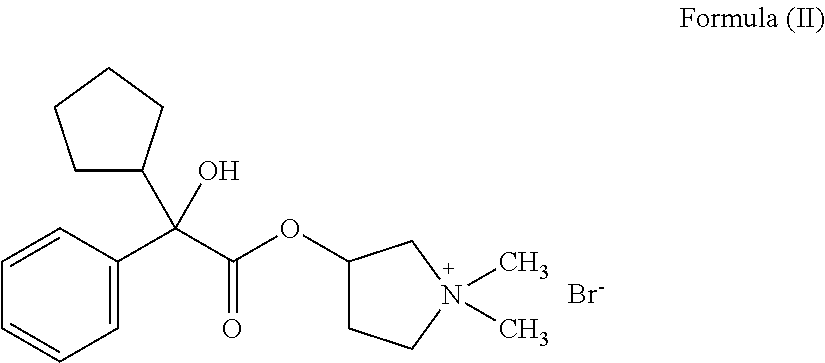

A cleaning composition is provided. The cleaning composition includes at least one polyamino-polycarboxylic acid or at least one salt thereof, at least one solvent, at least one substituted or non-substituted phenethylamine and water. The solvent is selected from a group consisting of glycols.

Owner:FERRO CORP

Method for treating organic wastewater containing aminopolycarboxylic acid

ActiveUS20050098498A1Reduce CODLow cost of treatmentShaking/oscillating/vibrating mixersElectrolysis componentsElectrolysisWastewater

The present invention provides a method for treating a wastewater which enables one to treat a difficultly biodegradable wastewater, particularly an organic wastewater containing aminopolycarboxylic acids to substantially decrease COD at a low cost, in which the method for treating an organic wastewater containing aminopolycarboxylic acids, comprising subjecting the organic wastewater containing aminopolycarboxylic acids to a high-speed electrolytic oxidation treatment, particularly, a method for treating an organic wastewater which comprises conducting treatment with microorganism subsequent to the high-speed electrolytic oxidation treatment.

Owner:FUJIFILM CORP

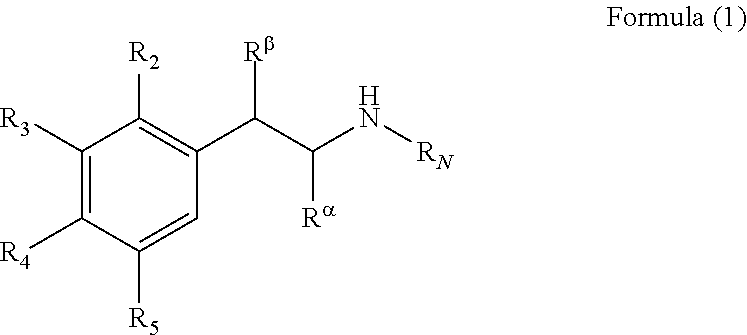

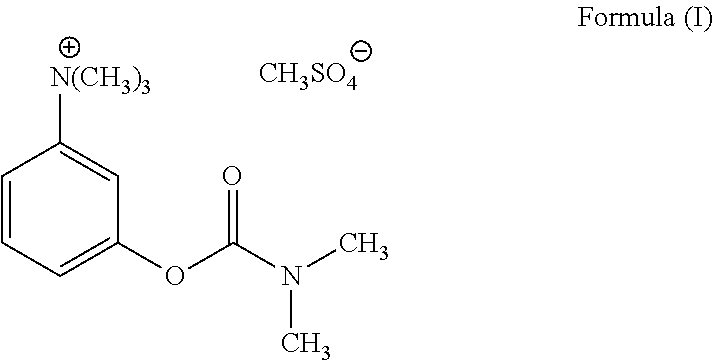

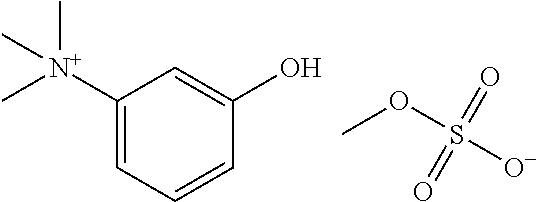

Ready-to-use injectable pharmaceutical compositions comprising neostigmine and glycopyrrolate

ActiveUS20190374462A1Pharmaceutical delivery mechanismPharmaceutical non-active ingredientsReady to useGlycopyrrolate

The present invention provides stable, ready-to-use injectable pharmaceutical compositions, comprising the combination of neostigmine, glycopyrrolate, a stabilizing amount of one or more aminopolycarboxylic acids, and a pharmaceutically acceptable liquid vehicle. Other aspects of the invention relate to methods for making such compositions and methods of using such compositions for reversing the effects of non-depolarizing neuromuscular blocking agents. Preferably, the composition comprises neostigmine methylsulfate, glycopyrronium bromide, ethylenediaminetetraacetic acid (EDTA) and a pharmaceutically acceptable liquid vehicle, and is provided in a pre-filled, ready-to-use sealed container, such as a pre-filled syringe, suitable for intravenous administration.

Owner:SLAYBACK PHARMA LLC

Indium oxalate dissolving agent composition

InactiveCN101876076AEffective dissolutionIncrease the maximum dissolvedNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingOxalateIndium

The invention provides an indium oxalate dissolving agent composition, which solves the prior problems. The indium oxalate dissolving agent chemically dissolves and removes the indium oxalate deposited on a wet etching device of a transparent conductive film formed by a tin indium oxide (ITO) film or an indium zinc oxide (IZO) film. The invention relates to a dissolving agent composition for dissolving and removing the indium oxalate deposited in the etching device system, characterized in that: the dissolving agent composition is an aqueous solution containing an alkali component and one or more two kinds of compounds selected from aminopolycarboxylic acid and its salt. The invention also relates to a cleaning method in the etching device system using the dissolving agent composition.

Owner:KANTO CHEM CO INC

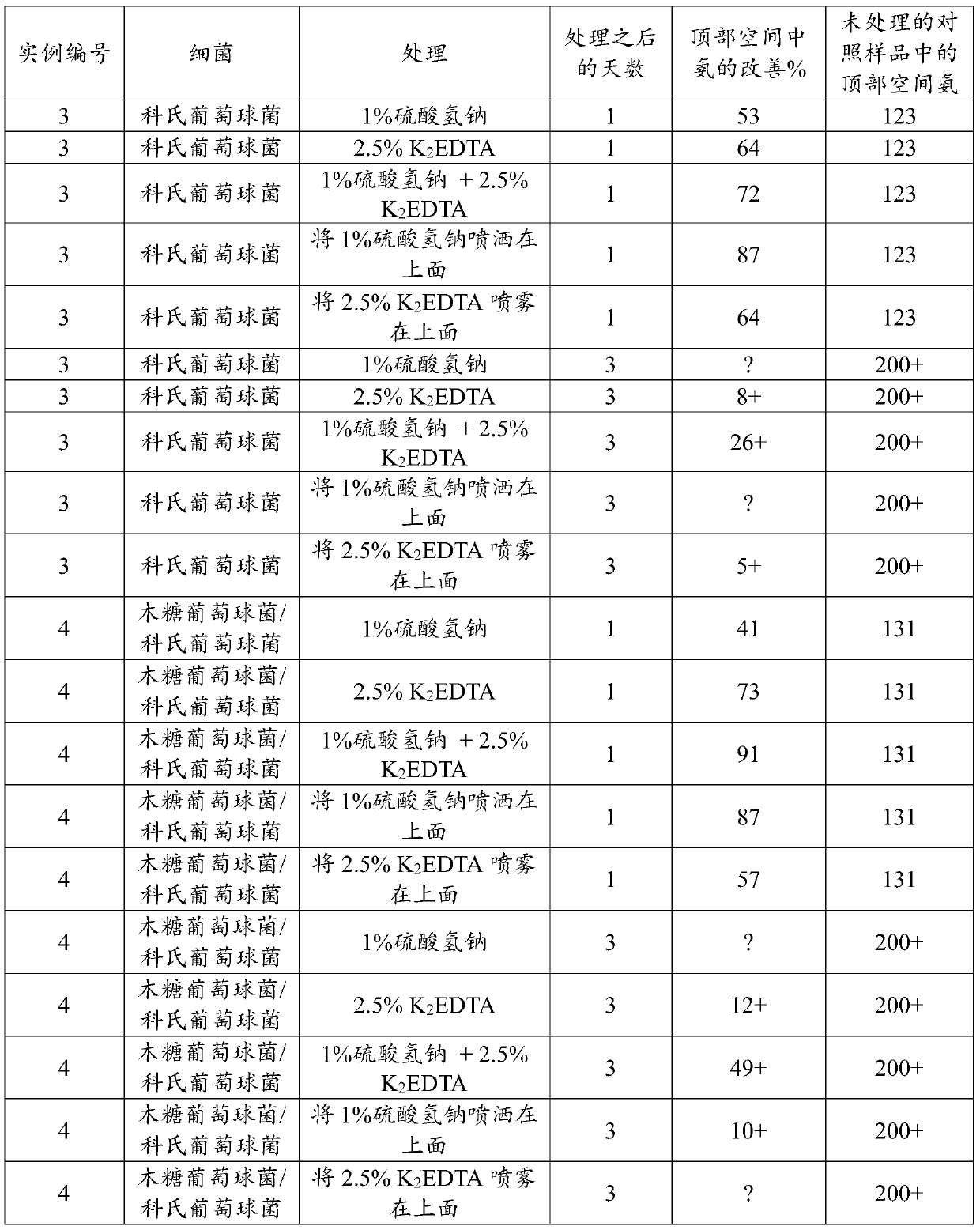

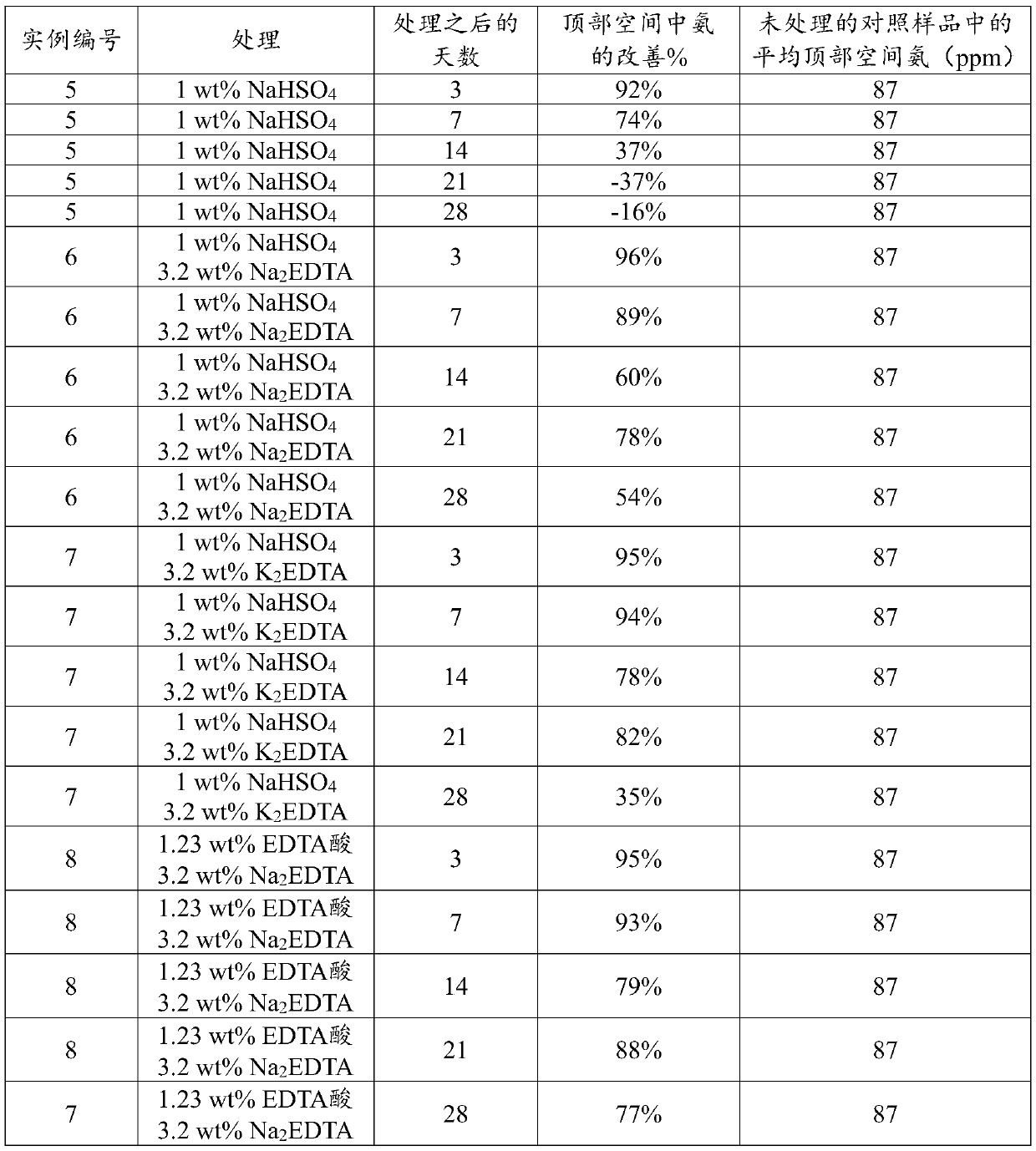

Methods for suppression of ammonia formation from staphylococcus-xylosus and staphylococcus-cohnii

InactiveCN109714956AAmmonia content improvementAnimal housingDeodrantsBiotechnologyStaphylococcus cohnii

A method for suppressing the formation of ammonia comprising providing a carrier material to a container having a headspace; providing a bacteria, an acidifier and an odor inhibitor to the carrier material, the bacteria comprising Staphylococcus-xylosus or Staphylococcus-cohnii bacteria, and the odor inhibitor comprising a salt of an aminopolycarboxylic acid compound; and applying animal waste tothe carrier material; wherein there is a 5 to 98 percent improvement of ammonia content in the headspace as compared to an untreated control comprising a container containing the carrier material andthe bacteria and not contain the odor inhibitor.

Owner:DOW GLOBAL TECH LLC +1

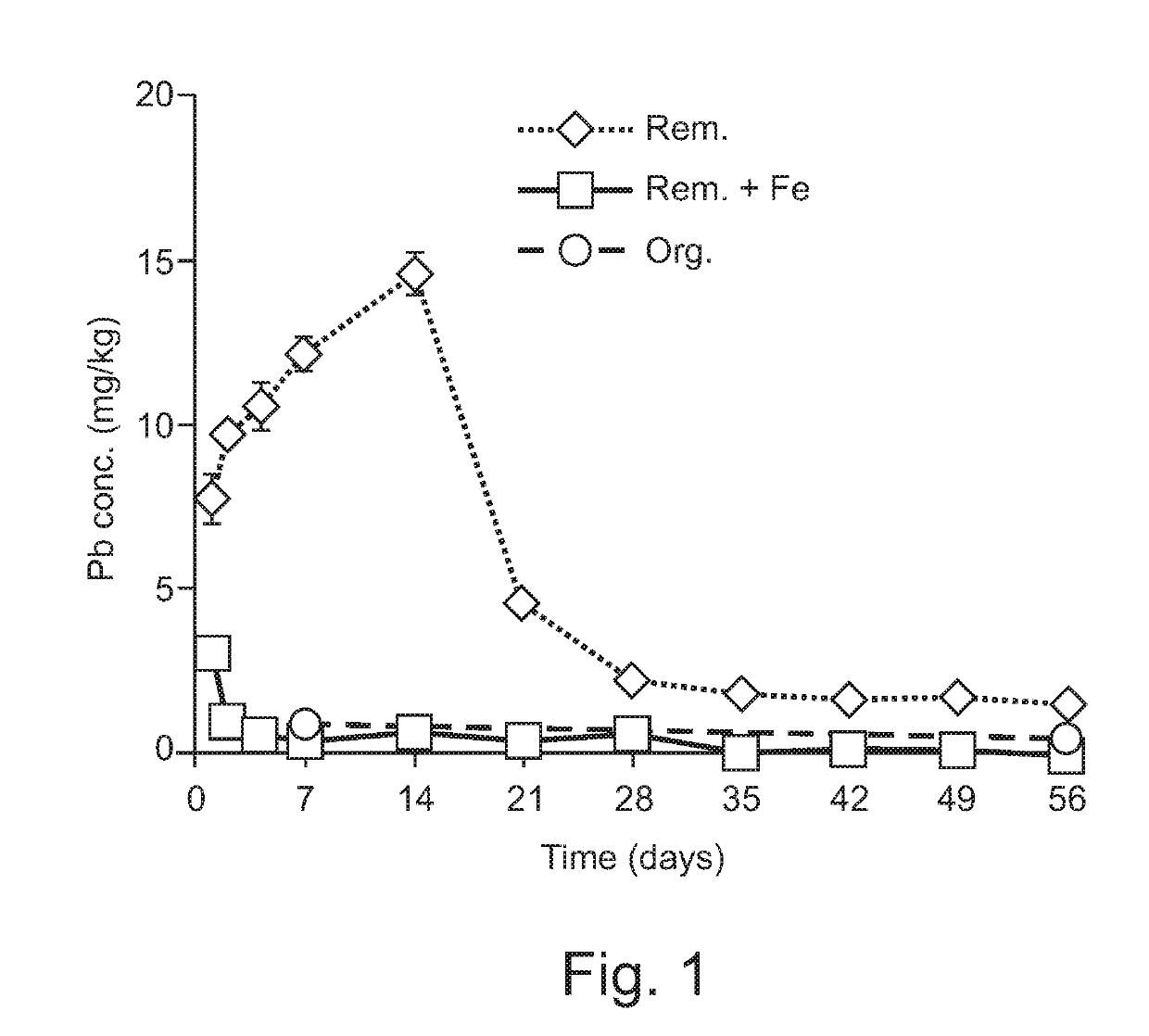

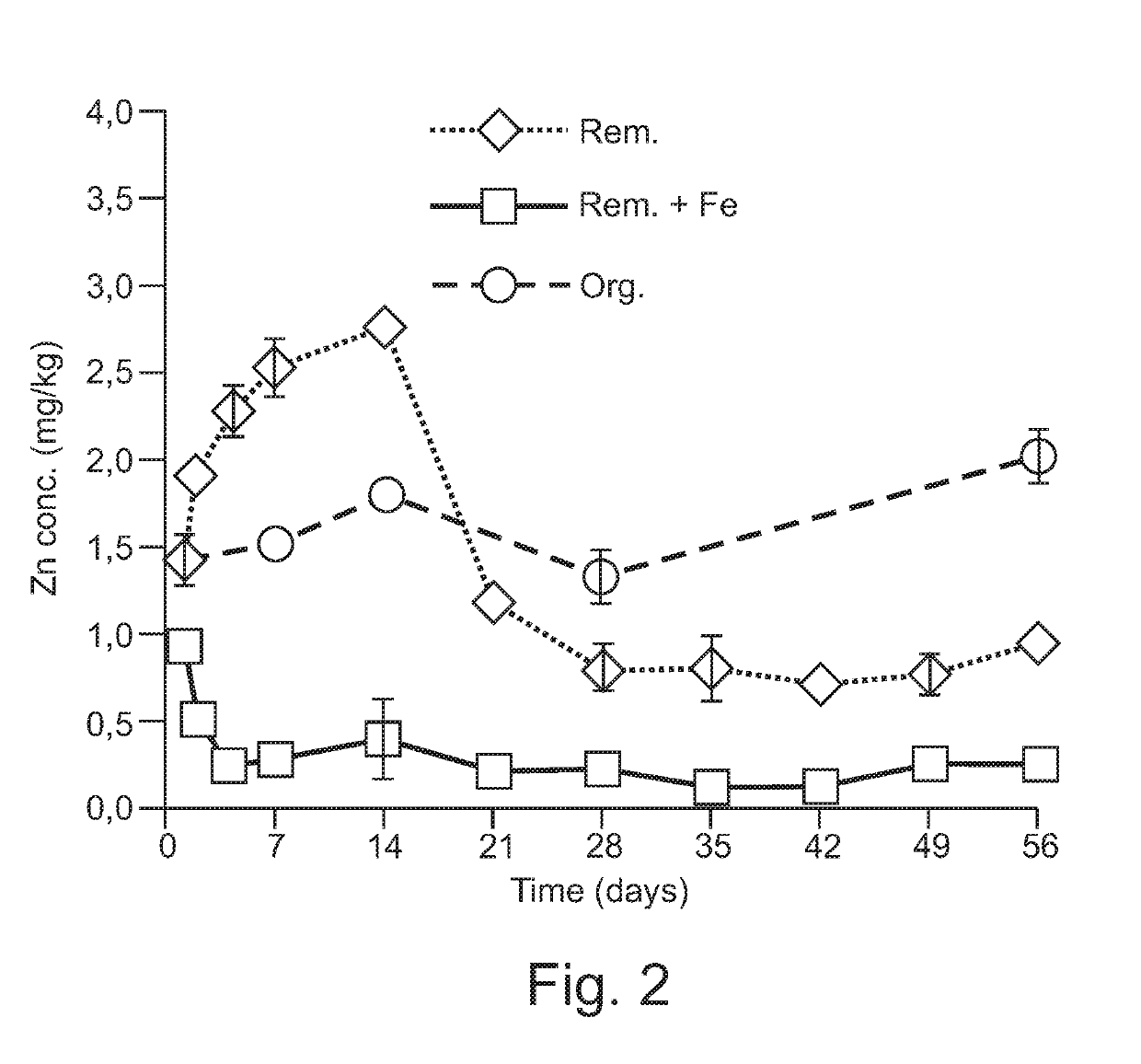

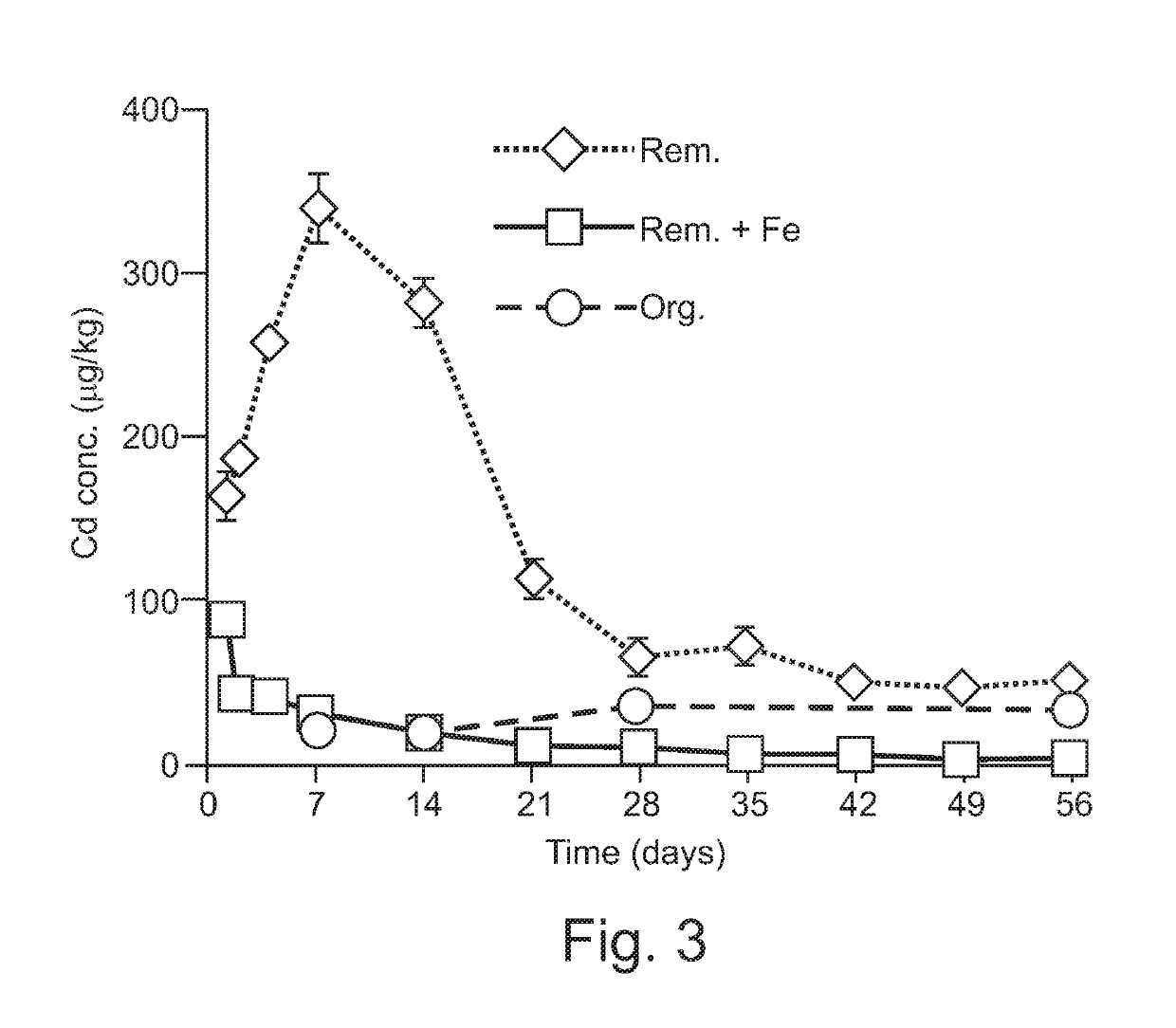

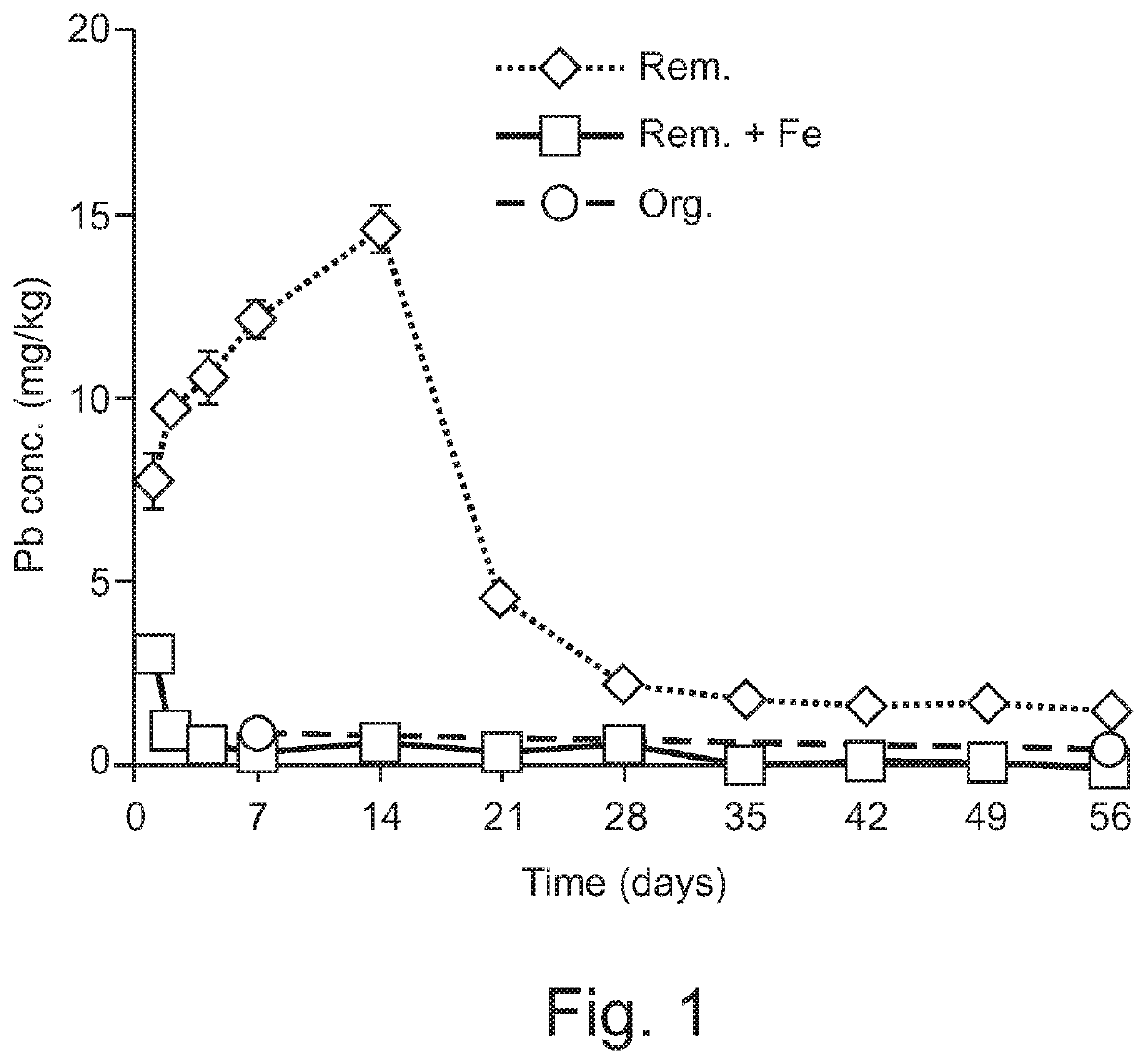

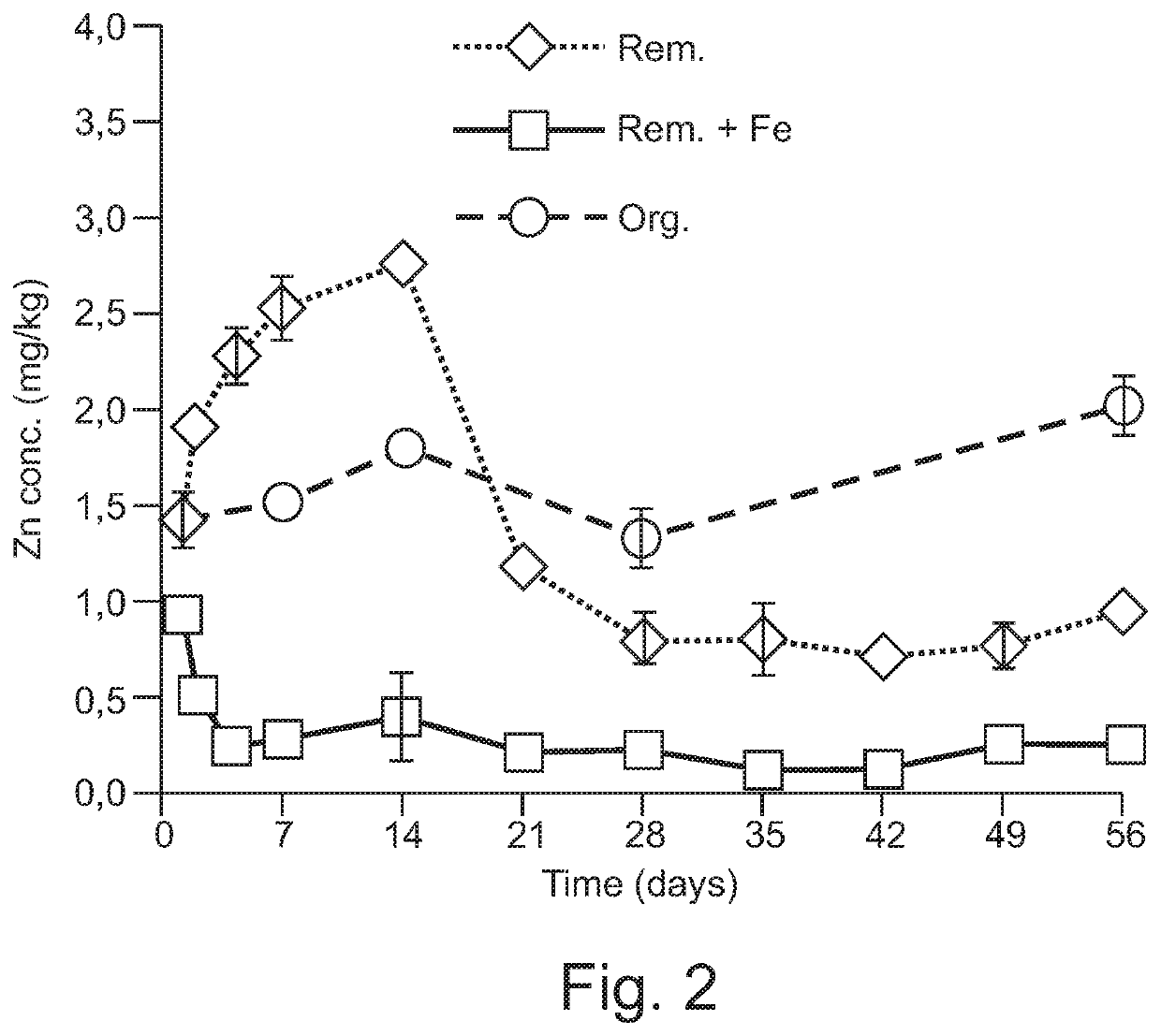

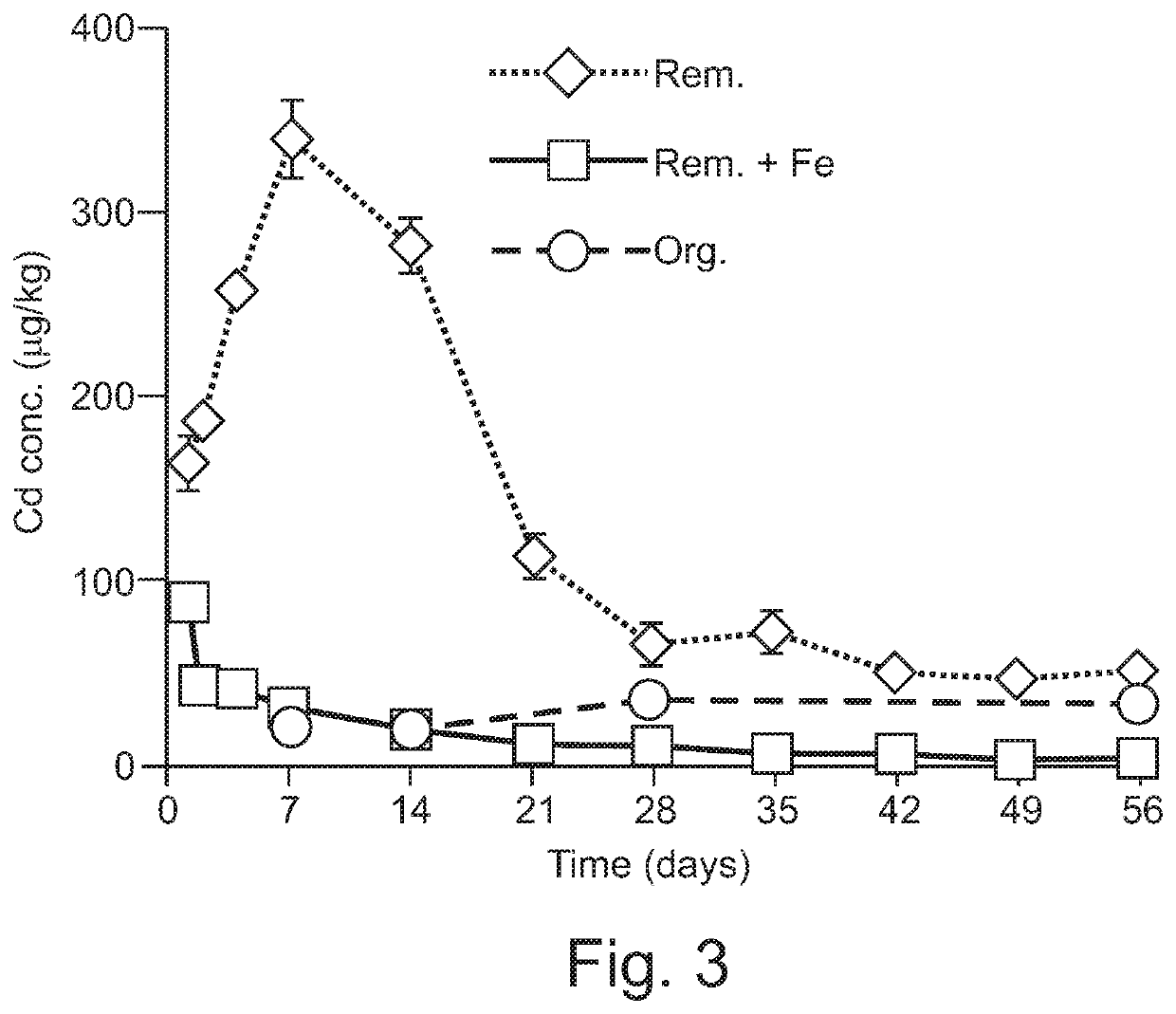

Curbing toxic emissions from remediated substrate

A process for curbing of emissions of toxic metals and chelating agent from remediated soils, sediments and other substrates contaminated with toxic metals, said process comprising: (a) remediation of contaminated soil, sediment and other substrate with washing solution, said washing solution comprising EDTA or other chelating agent from the group of aminopolycarboxylic acids and their salts and mixtures thereof; (b) addition of 0.05-5% (w / w, dry weight) of zero-valent Fe or Fe compounds from the group of Fe-oxides and Fe-oxide-hydroxides into the slurry phase of soil, sediment and other substrate; (c) mixing of Fe-amended slurry; (d) separation of solid phase of remediated and Fe-amended soil, sediment and other substrate; (e) ageing of remediated and Fe-amended soil, sediment and other substrate for 0.5-45 days.

Owner:ENVIT

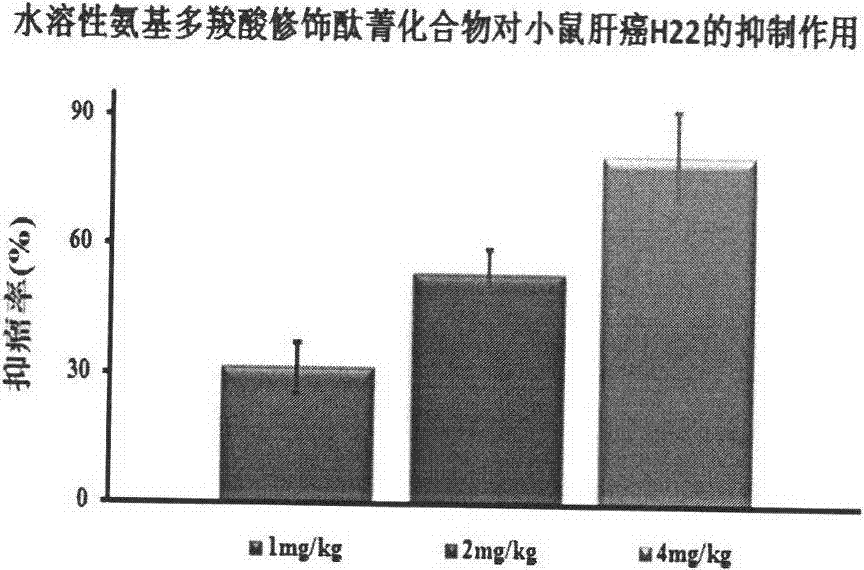

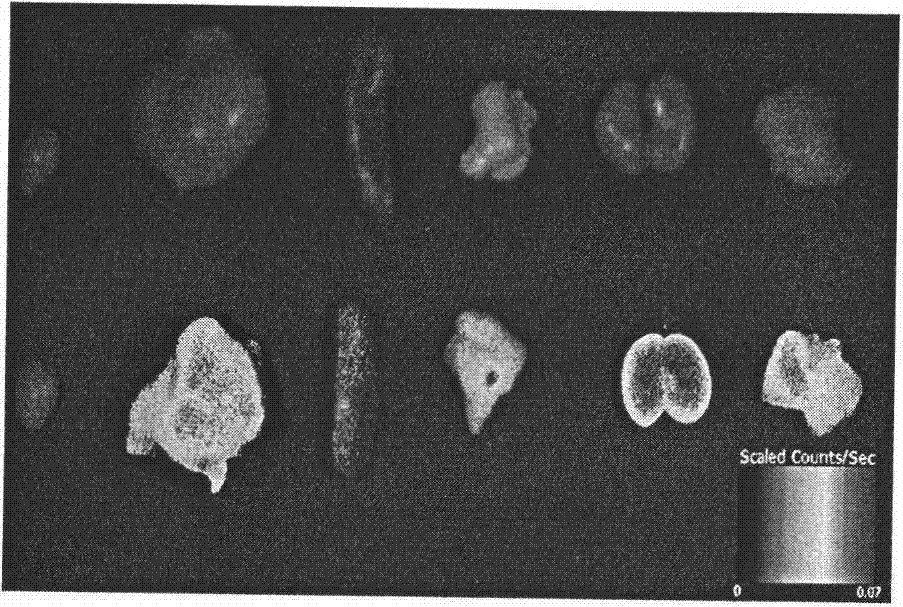

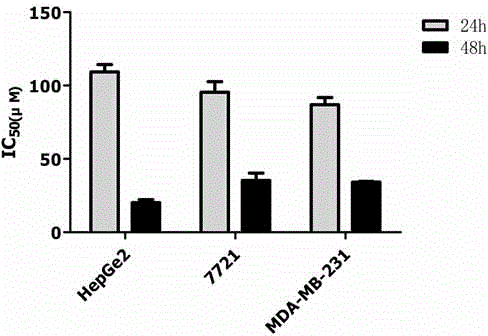

Synthesis of zinc phenanthroline aminopolycarboxylate complex and application of complex in anti-tumor drugs

InactiveCN104557990AHigh anticancer activitySmall side effectsOrganic active ingredientsAntineoplastic agentsPhenanthrolineCarboxylic acid

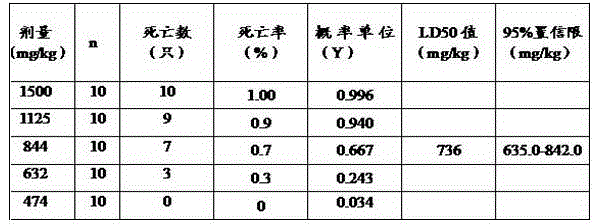

The invention discloses a zinc phenanthroline aminopolycarboxylate complex as well as a preparation method and an application thereof in anti-tumor drugs, and belongs to the field of an anti-tumor technology. The zinc phenanthroline aminopolycarboxylate complex disclosed by the invention is prepared by mixing, heating and reacting zinc salt, aminopolycarboxylic acid and phenanthroline in an aqueous phase. The complex is relatively strong in anti-tumor activity, and can be used as a raw material for preparing liver cancer and breast cancer treating drugs; compared with platinum-based anti-tumor drugs which are commonly used at present, the complex disclosed by the invention has the characteristics of high anti-tumor activity, low toxic and side effects, short crystallization and separation time, good water solubility, high purity, low raw material cost, simple preparation method and the like.

Owner:YANGZHOU UNIV

Aqueous hydrogen peroxide solution comprising a specific stabilizer

ActiveUS10729799B2Lower levelImprove propertiesBiocidePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCarboxylic acidAqueous solution

Owner:ARKEMA FRANCE SA

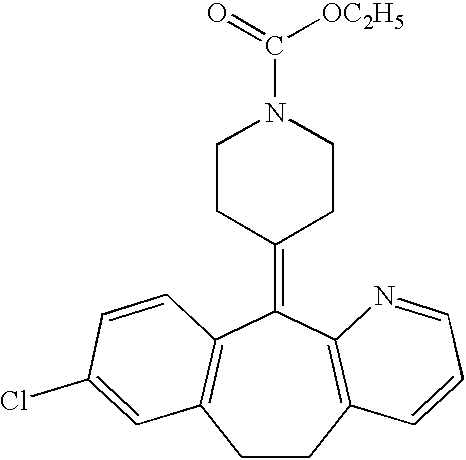

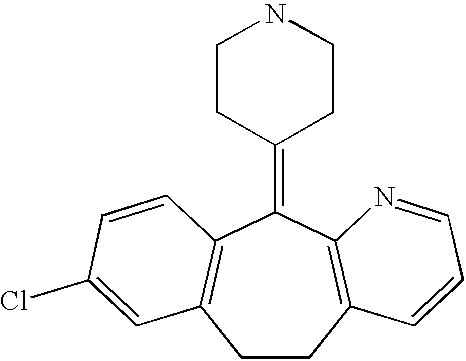

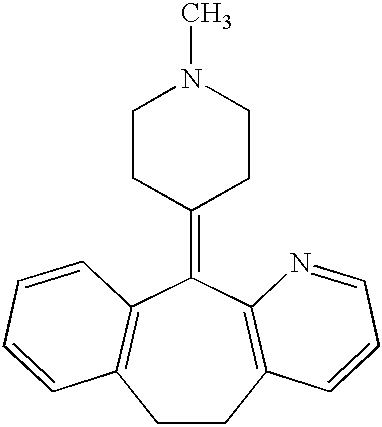

Stabilized antihistamine syrup

Owner:MERCK SHARP & DOHME CORP

Curbing toxic emissions from remediated substrate

A process for curbing of emissions of toxic metals and chelating agent from remediated soils, sediments and other substrates contaminated with toxic metals, said process comprising: (a) remediation of contaminated soil, sediment and other substrate with washing solution, said washing solution comprising EDTA or other chelating agent from the group of aminopolycarboxylic acids and their salts and mixtures thereof; (b) addition of 0.05-5% (w / w, dry weight) of zero-valent Fe or Fe compounds from the group of Fe-oxides and Fe-oxide-hydroxides into the slurry phase of soil, sediment and other substrate; (c) mixing of Fe-amended slurry; (d) separation of solid phase of remediated and Fe-amended soil, sediment and other substrate; (e) ageing of remediated and Fe-amended soil, sediment and other substrate for 0.5-45 days.

Owner:ENVIT

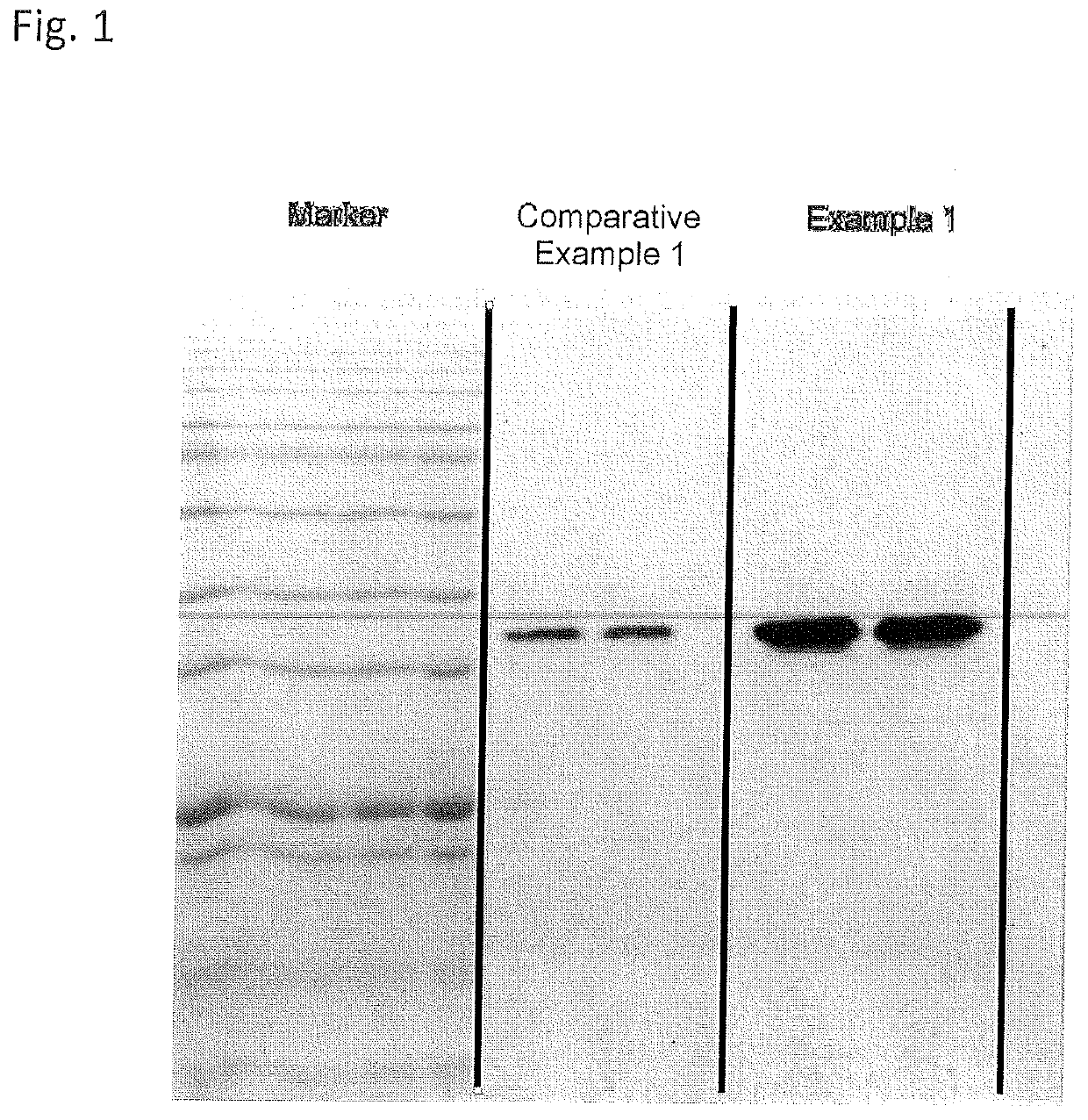

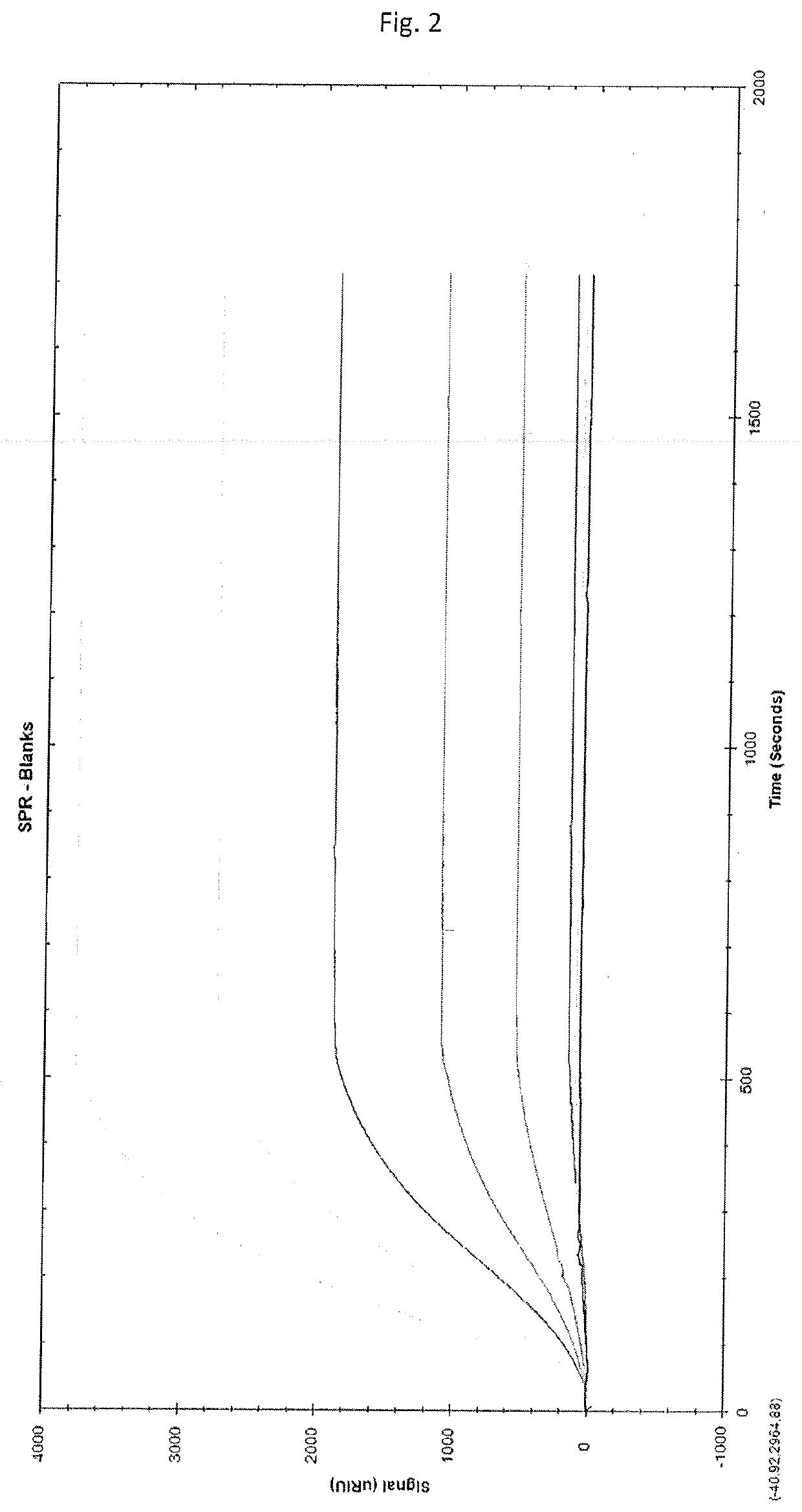

Solid-phase chelator material, method for producing thereof and use thereof for the purification of proteins

InactiveUS20220023851A1Other chemical processesSolid sorbent liquid separationBiochemical engineeringCarboxylic acid

A solid-phase chelator material usable for the purification of proteins. The solid-phase chelator material comprises a solid phase, polyamine groups bound to the solid phase and chelating groups bound to the polyamine groups. At least a part of the polyamine groups is connected with at least two chelating groups per polyamine group. Each chelating group comprises one or several aminopolycarboxylic acid groups (APA groups), with the proviso that the number of APA groups per polyamine group connected with at least two cheating groups is at least three.

Owner:CUBE BIOTECH GMBH

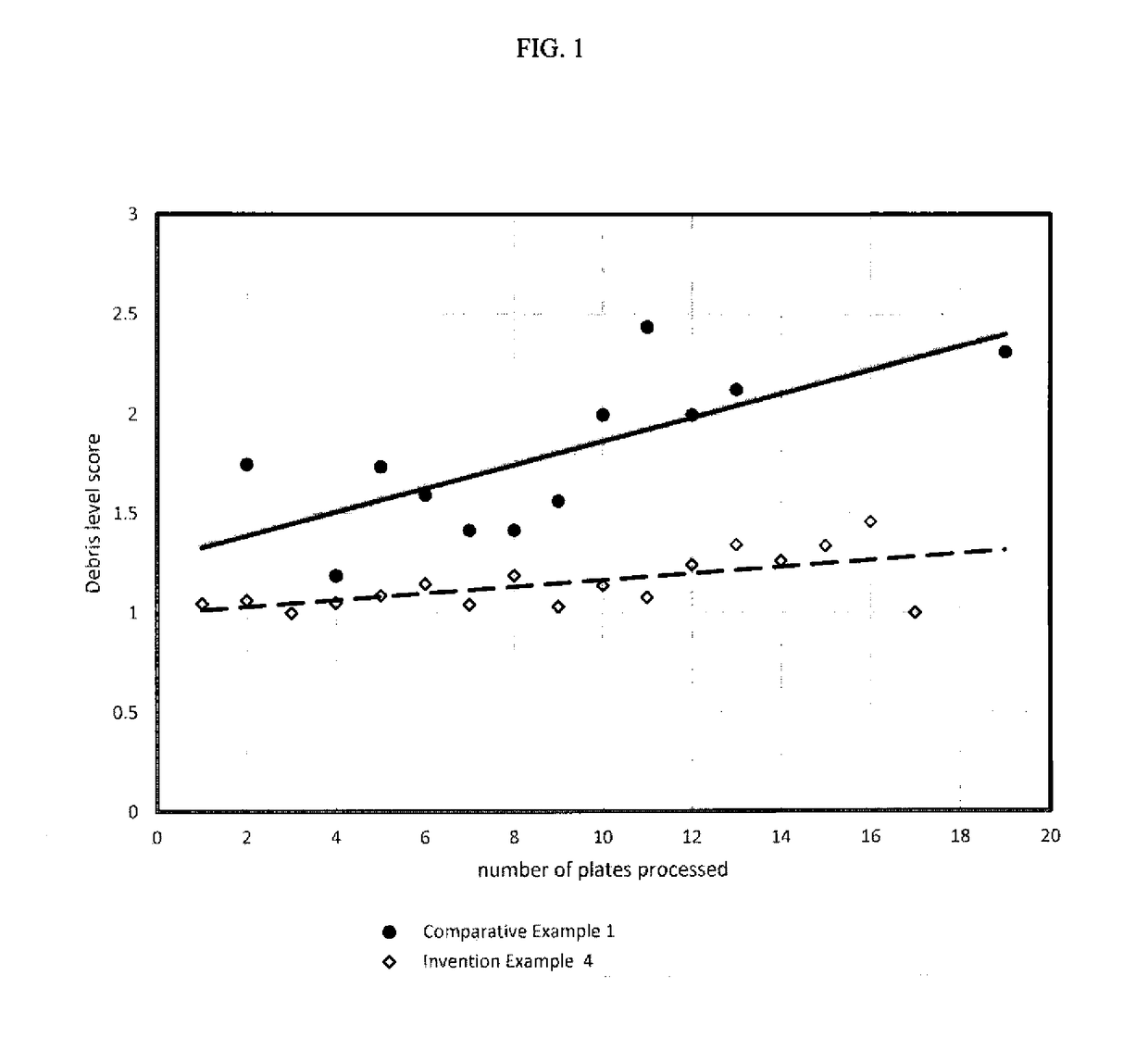

Method for preparing flexographic printing plates

ActiveUS10207491B2Efficiently providedPhotomechanical exposure apparatusPhotosensitive material processingControlled releaseWater dispersible

Flexographic printing members are prepared from a flexographic printing plate precursor consisting essentially of: backing film, water- or water-dispersible photosensitive layer, and cover sheet in contact with the photosensitive layer. The cover sheet is removed and a mask element is laminated directly in contact with the photosensitive layer. Exposure through the mask element provides exposed regions and non-exposed regions. The non-exposed regions are removed with an aqueous developer having: a) a C12-20 saturated or unsaturated fatty acid (or alkali metal salt) at 0.25-2.0 weight %, and at least 85 weight % of a C18 mono- or poly-unsaturated fatty acid (or alkali metal salt); b) an aminopolycarboxylic acid (or alkali metal salt) at 0.05-0.30 weight %; c) a buffer at 05-0.60 weight %; and d) water. The photosensitive layer has a controlled release of 5-500 g / cm using ASTM D-3330 Method D, between its front imaging surface and the mask element.

Owner:MIRACLON CORP

Flexographic developers and methods of use

PendingCN110199226AStable pHReduce debrisPhotosensitive material processingCompound (substance)Carboxylic acid

Flexographic printing members are prepared by developing an exposed flexographic printing member precursor with an aqueous flexographic developer. The aqueous flexographic developer comprises: a) a fatty acid composition consisting of one or more saturated or unsaturated fatty acids or alkali metal salts thereof, each saturated or unsaturated fatty acid or alkali metal salt thereof independently having 12 to 20 carbon atoms, the fatty acid composition being present in an amount of 0.25-2.0 weight %, and at least 85 weight % of the fatty acid composition is composed of one or more C18 mono- orpoly-unsaturated fatty acids or alkali metal salts thereof; b) an aminopolycarboxylic acid or alkali metal salt thereof in an amount of 0.05-0.30 weight %; c) a buffer compound in an amount of 05-0.60weight %; and d) water. Such aqueous flexographic developers can also be provided in concentrated form and appropriately diluted before or during use.

Owner:MIRACLON CORP

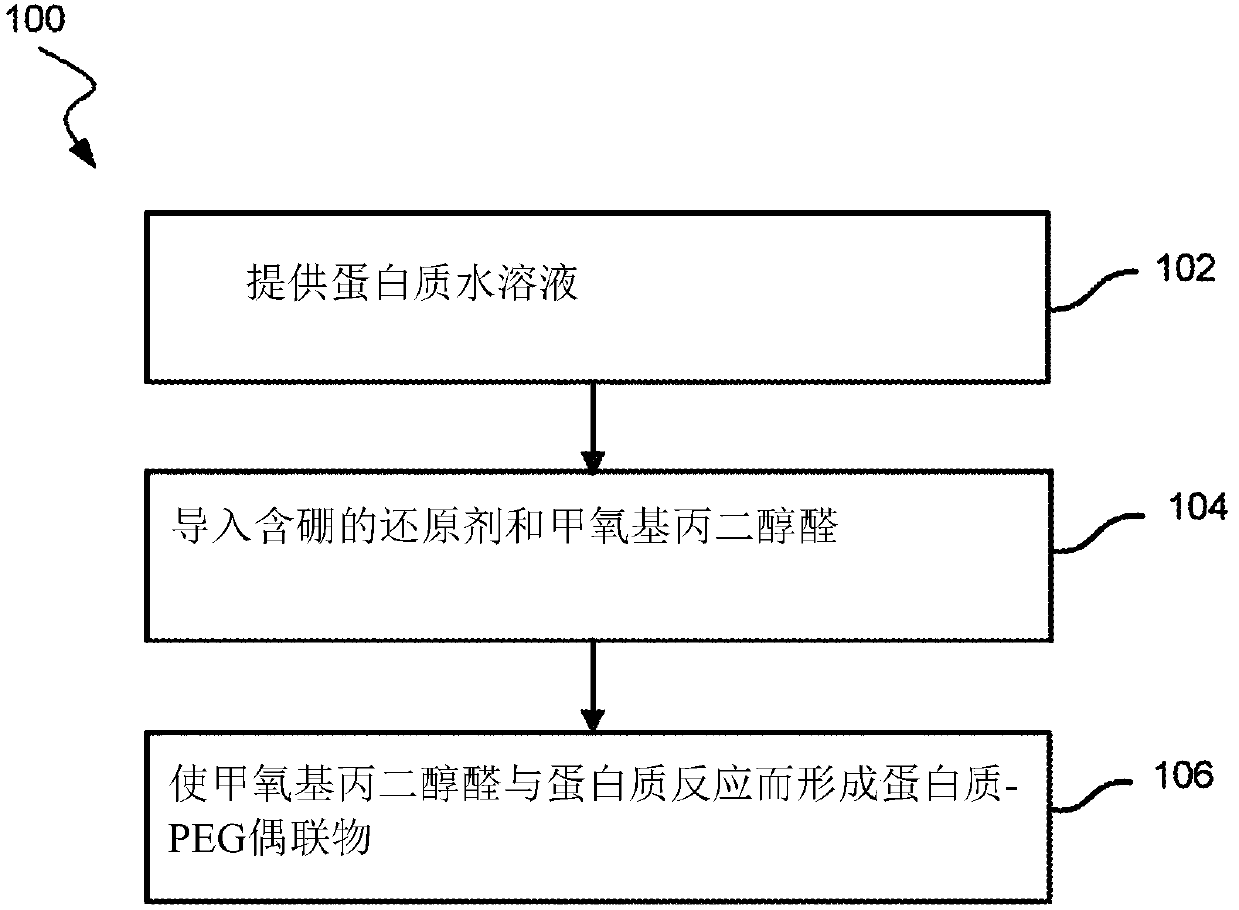

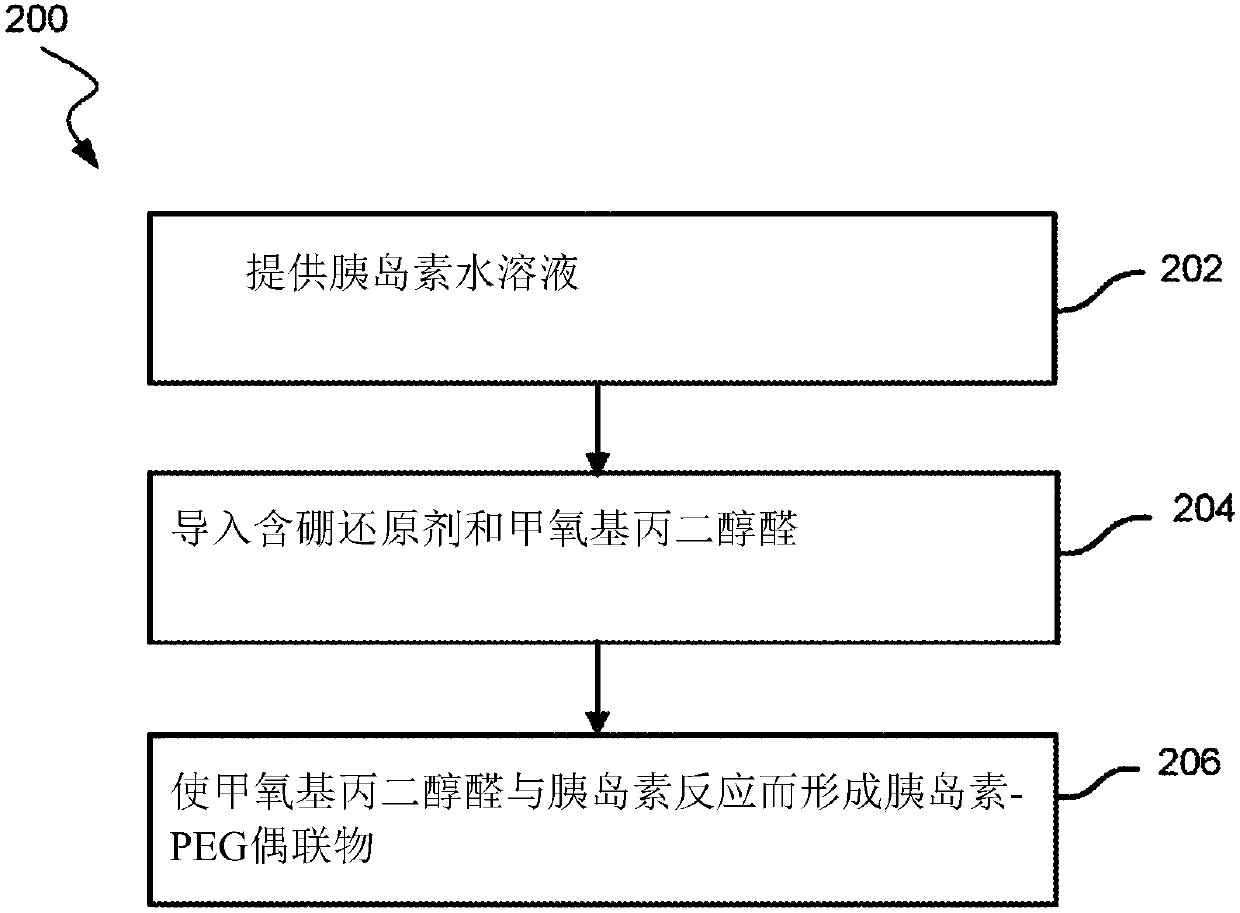

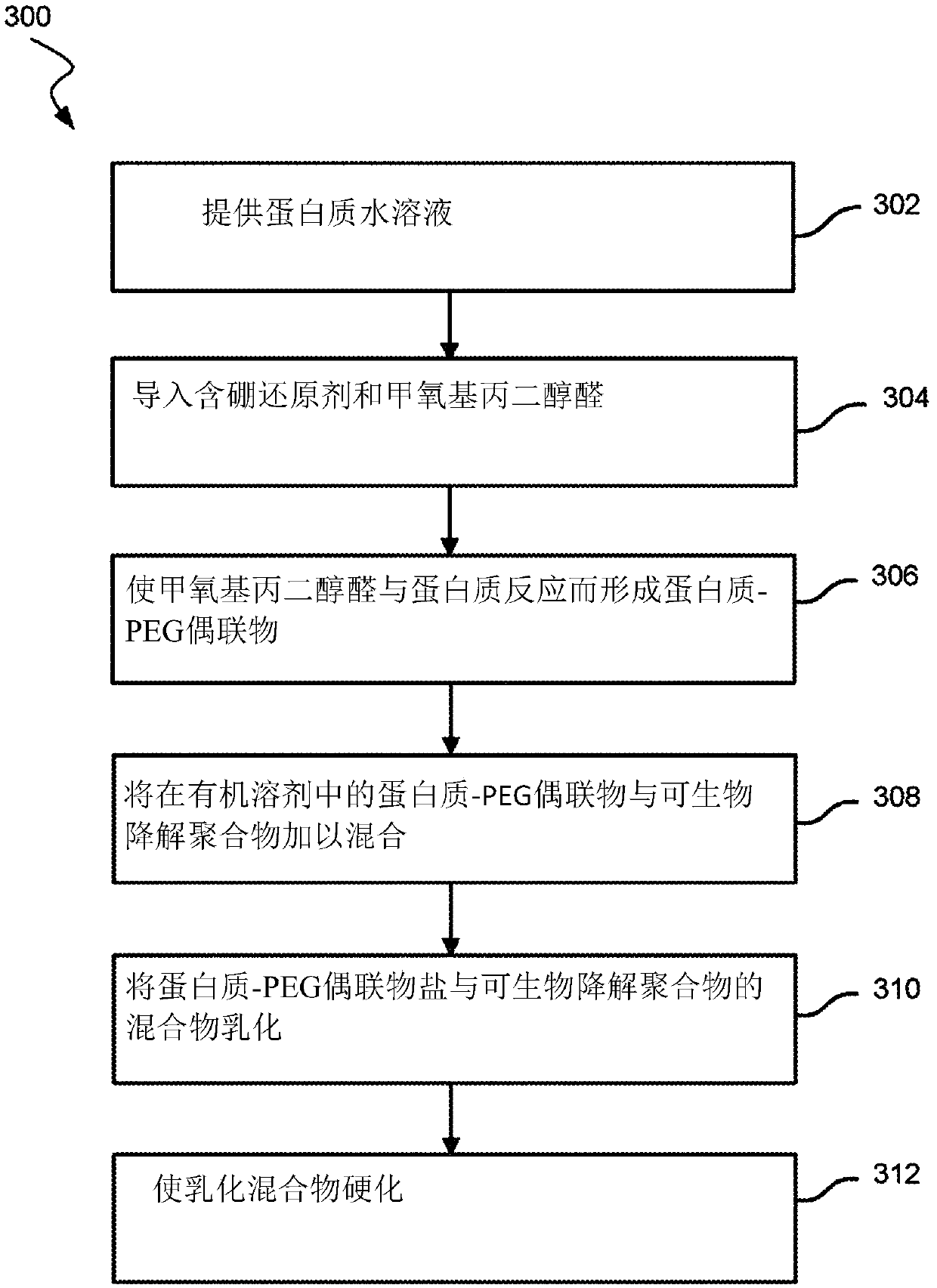

Amine pegylation methods for the preparation of site-specific protein conjugates

InactiveCN107708679ALow immunogenicityProlonged Circulatory Half-LifeOrganic active ingredientsPeptide/protein ingredientsProtein solutionFER protein

Examples include a method of making a protein-PEG conjugate. The method may include providing an aqueous protein solution. The aqueous protein solution may include a protein, a pH buffer, and a chelating agent. The chelating agent may be chosen from the group consisting of an aminopolycarboxylic acid, a hydroxyaminocarboxylic acid, an N-substituted glycine, 2-(2-amino-2-oxocthyl) aminoethane sulfonic acid (BES), and deferoxamine (DEF). The method may also include introducing sodium cyanoborohydride and a methoxy polyethylene glycol aldehyde to the aqueous protein solution. The sodium cyanoborohydride in the methoxy polyethylene glycol aldehyde may have a molar ratio ranging from about 5:1 to about 1.5:1. The method may further include reacting the methoxy polyethylene glycol aldehyde withthe protein to form the protein-PEG conjugate. The pH buffer may maintain a pH of the aqueous protein solution ranging from 4.0 to 4.4 during the reaction.

Owner:REZOLUTE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com