Method for treating organic waste salt through low-temperature catalytic pyrolysis and application

A low-temperature catalysis and pyrolysis technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of inability to fix transition metal impurities, affect the quality of inorganic salts, and have no resource utilization, etc. The effect of low temperature and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 50g of H acid-sodium sulfate waste salt (taken from the sodium sulfate waste salt produced in the H acid process) in a beaker, add 0.5g of cetyltrimethylammonium bromide, 100mL of water, 50°C Heat and stir well.

[0043] (2) Put the uniformly stirred mixture into an oven for drying at 80° C., grind and sieve (100 mesh).

[0044] (3) Put the ground and sieved mixed solid into a tube furnace, raise the temperature to 500° C. at 5° C. / min under a nitrogen atmosphere, and keep it warm for 2 hours.

[0045] (4) Dissolve the pyrolyzed solid matter in 150 mL of water, stir with a magnetic stirrer until all the inorganic salts are dissolved, then filter, and collect the filtrate and filter residue respectively.

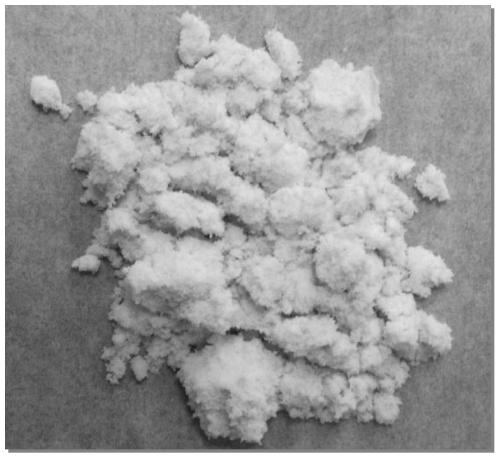

[0046] (5) The filtrate was evaporated and recrystallized in an oven at 80° C. to obtain sodium sulfate.

[0047] (6) Washing the filter residue with water and pickling multiple times to thoroughly remove impurities, freeze-drying, and graphitizing at 1000°...

Embodiment 2

[0050] (1) Weigh 50g of H acid-sodium sulfate waste salt into a beaker, add 0.5g of dodecyltrimethylammonium bromide, 100mL of water, heat and stir at 50°C until uniform.

[0051] (2) Move the refluxed solution to a beaker, put it into an oven for drying at 80° C., grind and sieve (100 mesh).

[0052] (3) Put the ground and sieved mixed solid into a tube furnace, raise the temperature to 500° C. at 5° C. / min under a nitrogen atmosphere, and keep it warm for 2 hours.

[0053] (4) Dissolve the pyrolyzed solid matter in 150 mL of water, stir with a magnetic stirrer until all the inorganic salts are dissolved, then filter, and collect the filtrate and filter residue respectively.

[0054] (5) The filtrate was evaporated and recrystallized in an oven at 80° C. to obtain sodium sulfate.

[0055] (6) After the filter residue is washed with water and pickled multiple times to thoroughly remove impurities, it is freeze-dried and graphitized at 1000° C. to obtain carbon nanomaterials. ...

Embodiment 3

[0058] (1) Weigh 50g of H acid-sodium sulfate waste salt beaker, add 0.5g of ammonium bromide, 100mL of water, heat and stir at 50°C until uniform.

[0059] (2) Move the refluxed solution to a beaker, put it into an oven for drying at 80° C., grind and sieve (100 mesh).

[0060] (3) Put the ground and sieved mixed solid into a tube furnace, raise the temperature to 500° C. at 5° C. / min under a nitrogen atmosphere, and keep it warm for 2 hours.

[0061] (4) Dissolve the pyrolyzed solid matter in 150 mL of water, stir with a magnetic stirrer until all the inorganic salts are dissolved, then filter, and collect the filtrate and filter residue respectively.

[0062] (5) The filtrate was evaporated and recrystallized in an oven at 80° C. to obtain sodium sulfate.

[0063] (6) After the filter residue is washed with water and pickled multiple times to thoroughly remove impurities, it is freeze-dried and graphitized at 1000° C. to obtain carbon nanomaterials.

[0064] This embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com