Method for purifying carbon nanotubes and method for preparing carbon nanotube slurry

A carbon nanotube and purification method technology, applied in the directions of carbon nanotubes, nanocarbons, structural parts, etc., can solve the problems of small removal effect of metal impurities, long reaction time, complicated process, etc. Low pollution and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

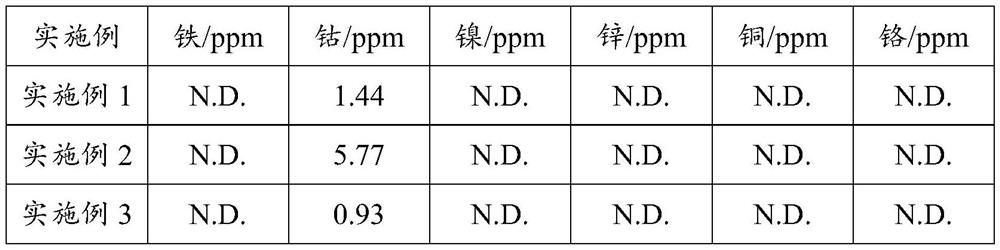

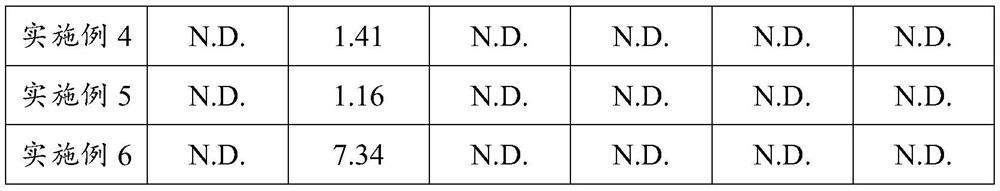

Embodiment 1

[0038] The present embodiment provides a method for purifying carbon nanotubes, comprising the following steps:

[0039] (1) Put the original carbon nanotube powder into a twin-screw extruder, compress and granulate, and the size of the compressed carbon nanotube particles is: length 5mm, diameter 5mm.

[0040] (2) Take 50g of compressed carbon nanotube particles and put them on the high-temperature non-metallic filter element of the high-temperature furnace in the vertical quartz reactor, connect the chlorine gas cylinder and the nitrogen gas cylinder, and feed 1000sccm from the bottom of the quartz reactor. N 2 , hold for 15min to exhaust the air in the device. Then the temperature of the high-temperature furnace was raised from room temperature to 1000°C, and 500sccm Cl was introduced at this time. 2 , hold for 120 min, then turn off Cl 2 , lower the temperature of the high temperature furnace to room temperature. Among them, in the whole process of purification, 1000 scc...

Embodiment 2

[0044] The present embodiment provides a method for purifying carbon nanotubes, comprising the following steps:

[0045] (1) Put the original carbon nanotube powder into a twin-screw extruder, compress and granulate, and the size of the compressed carbon nanotube particles is: length 5mm, diameter 5mm.

[0046] (2) Take 50g of compressed carbon nanotube particles and put them on the high-temperature non-metallic filter element of the high-temperature furnace in the vertical quartz reactor, connect the chlorine gas cylinder and the nitrogen gas cylinder, and feed 1000sccm from the bottom of the quartz reactor. N 2 , hold for 15min to exhaust the air in the device. Then the temperature of the high-temperature furnace was raised from room temperature to 1000°C, and 200sccm Cl was introduced at this time. 2 , hold for 120 min, then turn off Cl 2 , lower the temperature of the high temperature furnace to room temperature. Among them, in the whole process of purification, 1000 s...

Embodiment 3

[0050] The present embodiment provides a method for purifying carbon nanotubes, comprising the following steps:

[0051] (1) Put the original carbon nanotube powder into a twin-screw extruder, compress and granulate, and the size of the compressed carbon nanotube particles is: length 5mm, diameter 5mm.

[0052] (2) Take 50g of compressed carbon nanotube particles and put them on the high-temperature non-metallic filter element of the high-temperature furnace in the vertical quartz reactor, connect the chlorine gas cylinder and the nitrogen gas cylinder, and feed 1000sccm from the bottom of the quartz reactor. N 2 , hold for 15min to exhaust the air in the device. Then the temperature of the high-temperature furnace was raised from room temperature to 1000°C, and 800sccm Cl was introduced at this time. 2 , keep for 120min, then turn off Cl 2 , lower the temperature of the high temperature furnace to room temperature. Among them, in the whole process of purification, always ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com