Natural gas sulfur recovery and catalyst regeneration device and method

A sulfur recovery and catalyst technology, applied in chemical instruments and methods, chemical recovery, separation methods, etc., to achieve the effects of reducing decomposition, efficient removal, and reducing the scale of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

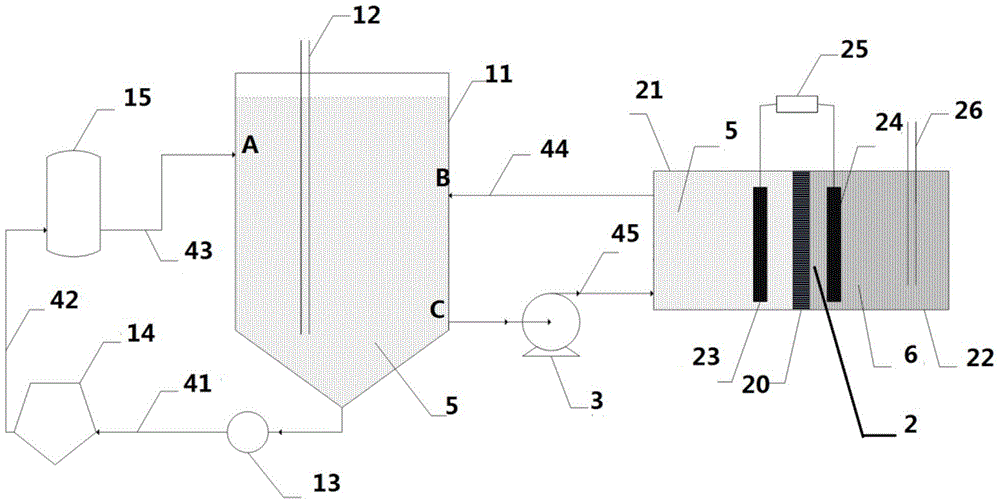

[0014] like figure 1 As shown, the natural gas sulfur recovery and catalyst regeneration device includes: sulfur recovery reactor 11 , separation pump 13 , sulfur separation device 14 , liquid storage tank 15 , fuel cell 2 and circulation pump 3 .

[0015] The sulfur recovery reactor 11 is a closed structure equipped with a complex iron catalyst 5; the upper part of the sulfur recovery reactor 11 is a cylinder and the lower part is a cone, the upper part is a cylinder to facilitate the increase of the container volume, and the lower part is a cone to facilitate sulfur deposition;

[0016] The top of the sulfur recovery reactor 11 is provided with a hydrogen sulfide inlet pipe 12, and the hydrogen sulfide gas enters the sulfur recovery reactor 11 through the hydrogen sulfide inlet pipe 12;

[0017] The bottom end of the cone (cone tip) of the sulfur recovery reactor 11 is provided with a deposited sulfur output port to facilitate the deposited sulfur output;

[0018] The cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com