Separation and preparation method of ligustilide

A technology of ligustrazolide and chuanxiong, which is applied in the field of separation and preparation of ligustrazolide, and achieves the effects of simple operation, less solvent consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of Rhizoma Chuanxiong Extract:

[0029] Weigh Rhizoma Chuanxiong, then add 5 times the volume of ethanol, heat and reflux for extraction for 1 hour, let it stand, filter, extract the medicinal residue twice with the above method, combine the extracts, and then distill and recover the solvent under reduced pressure in a water bath to obtain Ligusticum Chuanxiong Extract The medicinal extract, the Chuanxiong extract extract is dispersed with 7 times the volume of water, and then extracted 5 times with ethyl acetate to obtain the ethyl acetate extract;

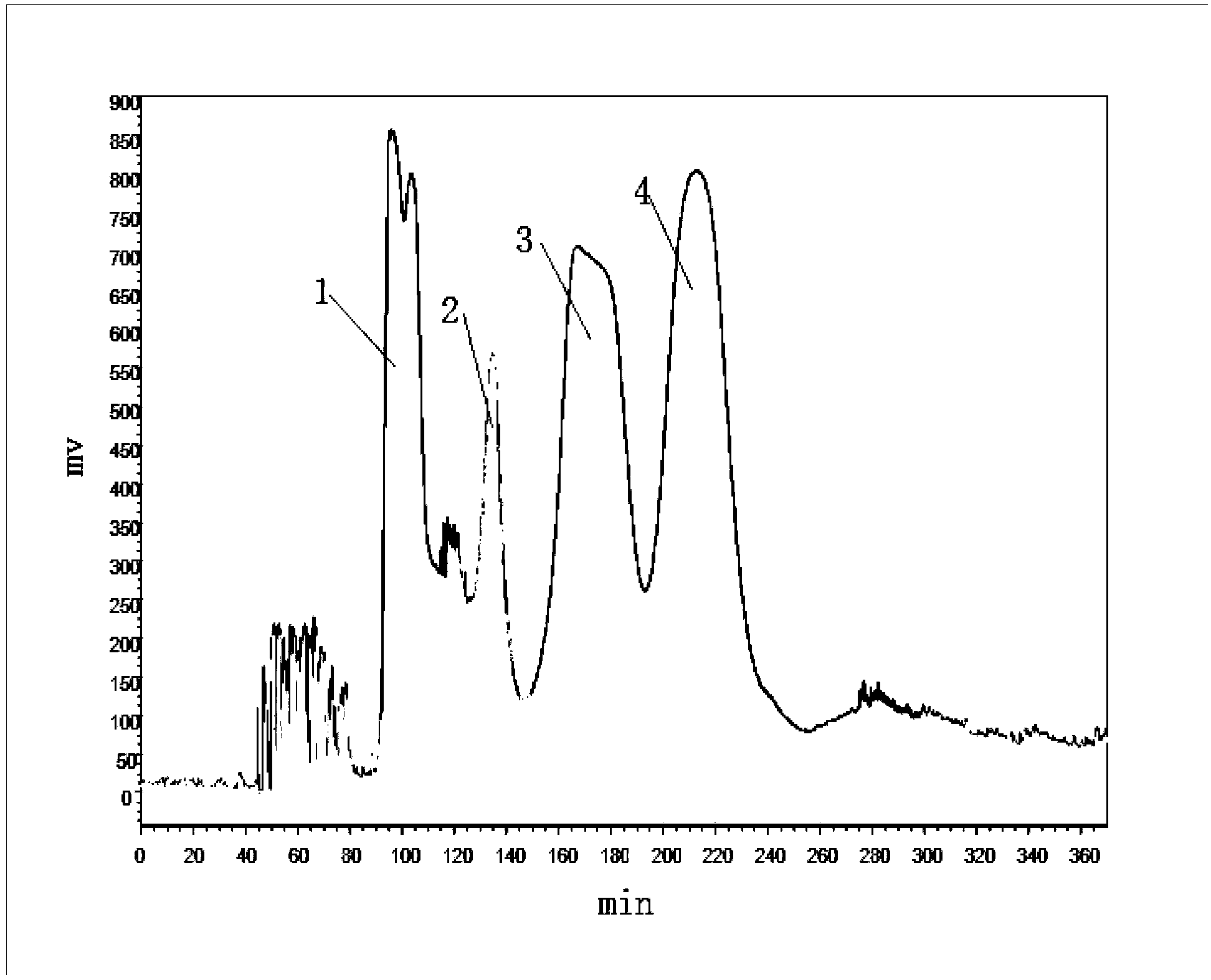

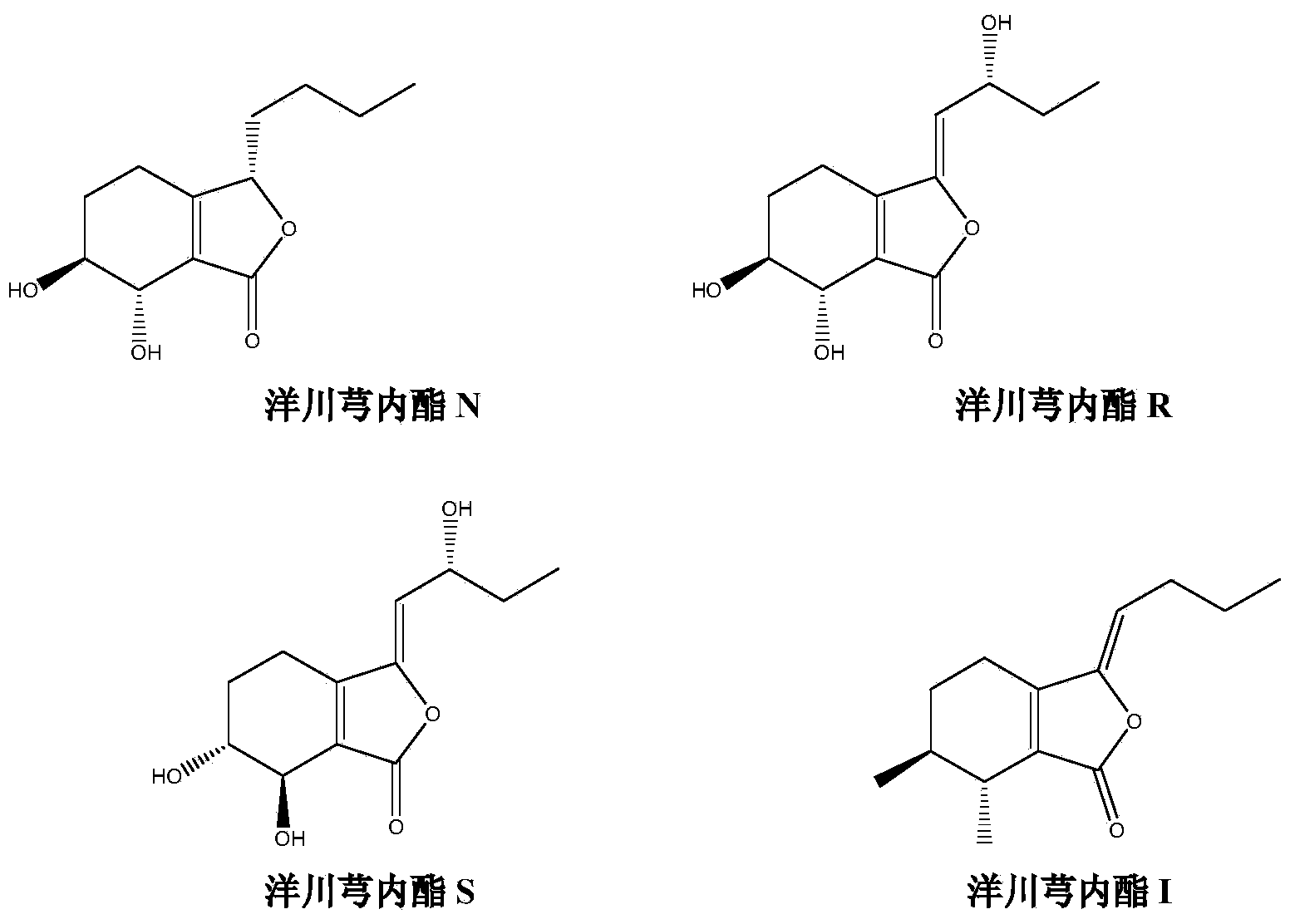

[0030] (2) separation and preparation of Ligusticolactone by high-speed countercurrent chromatography:

[0031] The two-phase solvent system uses n-hexane:ethyl acetate:ethanol:water volume ratio of 4:5:4:5. Before use, separate the upper and lower phases, and ultrasonically 20min. The upper phase of the solvent system is the stationary phase, and the lower phase is the mobile phase. Phase, pump the upper ph...

Embodiment 2

[0033] (1) Preparation of Rhizoma Chuanxiong Extract:

[0034] Weigh Rhizoma Chuanxiong, then add 12 times the volume of ethanol, heat and reflux for extraction for 3 hours, let it stand, filter, extract the medicinal residues twice again with the above method, combine the extracts, and then distill the solvent under reduced pressure in a water bath to obtain Ligusticum Chuanxiong Extract The medicinal extract, the Rhizoma Chuanxiong extract extract was dispersed with 13 times the volume of water, and then extracted 5 times with ethyl acetate to obtain the ethyl acetate extract;

[0035] (2) separation and preparation of Ligusticolactone by high-speed countercurrent chromatography:

[0036] The two-phase solvent system adopts cyclohexane:ethyl acetate:ethanol:water volume ratio of 5:6:5:6, separates the upper and lower phases before use, and ultrasonicates for 40min. The upper phase of the solvent system is used as the stationary phase, and the lower phase is For the mobile p...

Embodiment 3

[0038] (1) Preparation of Rhizoma Chuanxiong Extract

[0039] Take 1000g of Rhizoma Chuanxiong medicinal material, add 95% ethanol with 8 times the volume of medicinal material, heat and reflux for extraction for 2 hours, let it stand, and filter; use the same method to extract the medicinal residue twice, combine the extracts, and recover the solvent under reduced pressure in a water bath at 85°C. Chuanxiong extract extract was obtained; Chuanxiong extract extract was dispersed with 10 times the volume of water and extracted 5 times with ethyl acetate to obtain ethyl acetate extract as the test sample.

[0040] (2) Separation and preparation of chuanxiong lactone by high-speed countercurrent chromatography (HSCCC)

[0041] According to the results of partition coefficient determination, cyclohexane:petroleum ether:ethanol:water (4.5:5.5:4:6) was used in the two-phase solvent system, and the upper and lower phases were separated before use, and ultrasonicated for 30min. Use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com