Method for preparing cinnamtannin B1

A technology of methanol and lychee leaves, applied in the field of natural products, can solve problems such as limited and active substance composition to be studied, and achieve the effect of increasing added value and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

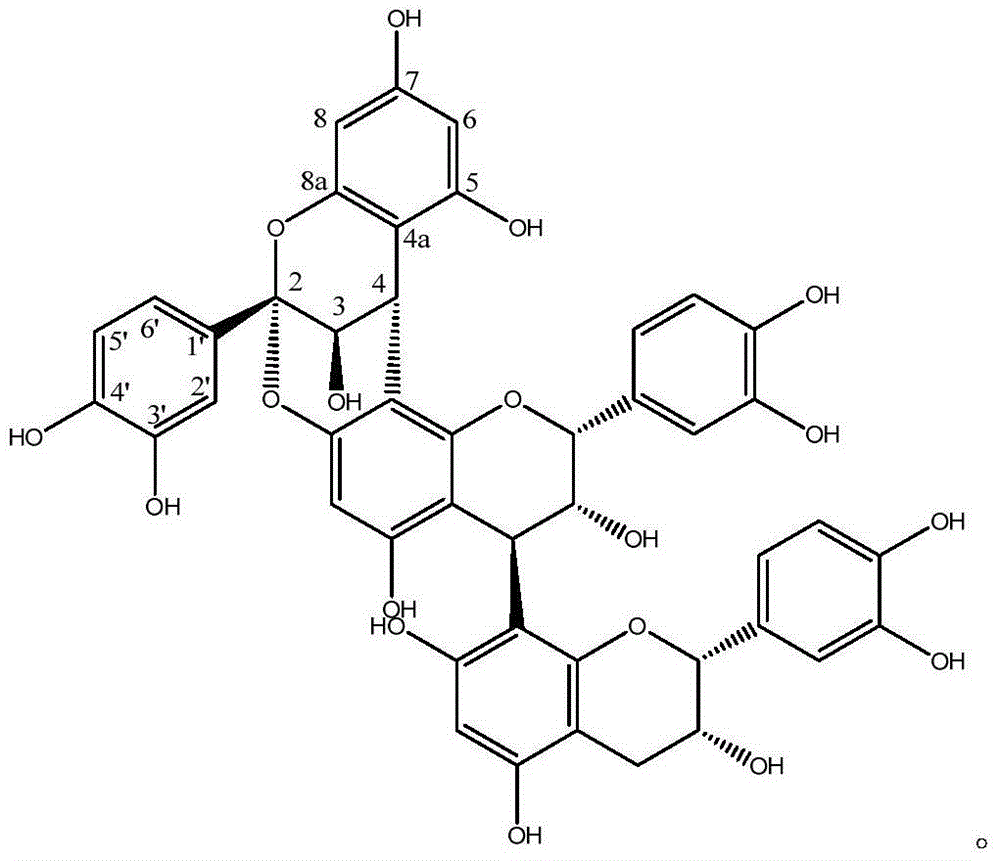

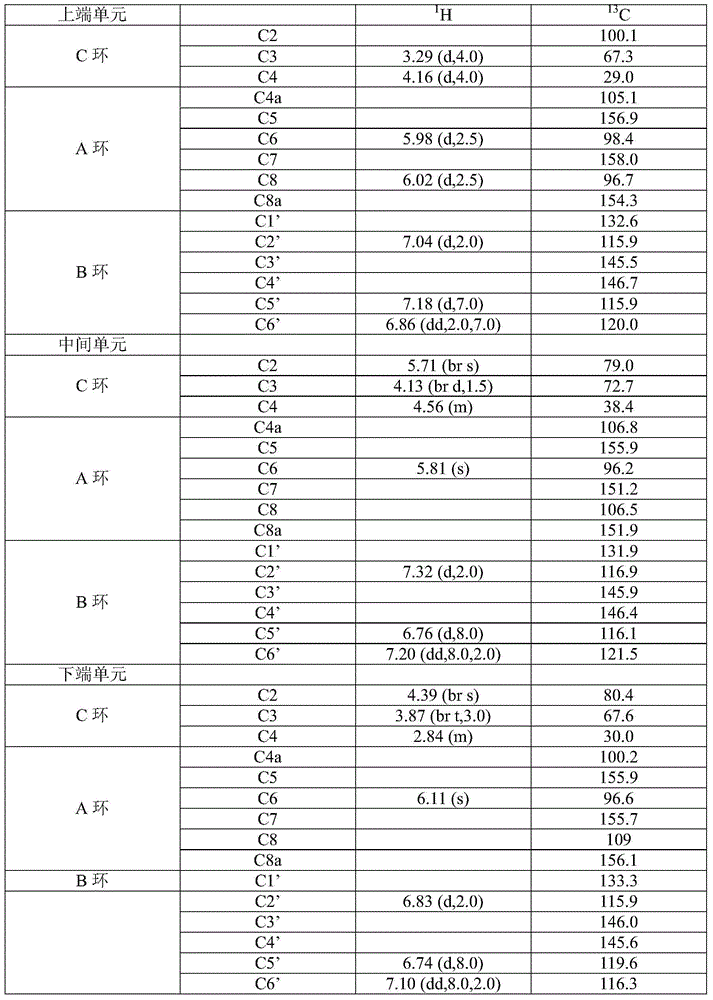

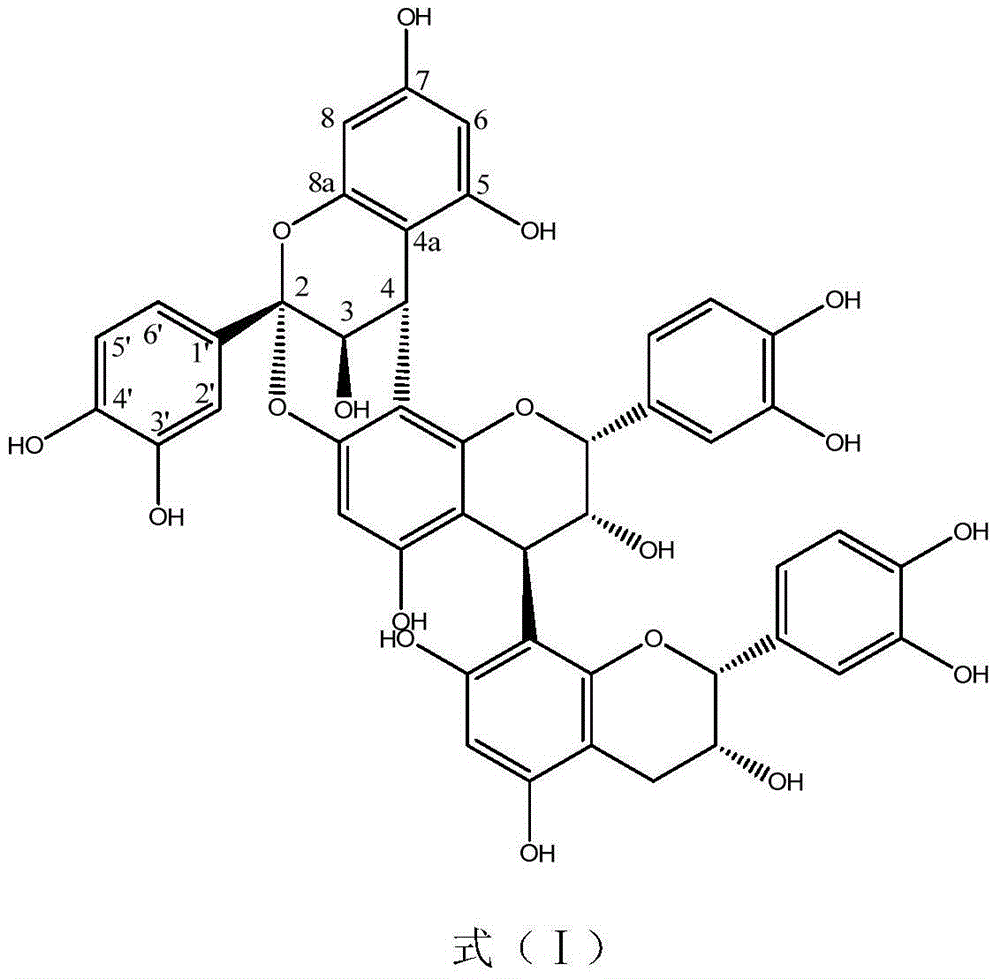

[0014] Example 1: Preparation, isolation and structural identification of cinnamtannin B1.

[0015] 1. Preparation and separation of cinnamtannin B1

[0016] 1) Material selection: choose fresh lychee leaves, wash with water;

[0017] 2) drying and pulverizing: drying or drying the lychee leaves, using a pulverizer to pulverize them into powder, and passing through a 20-mesh sieve to obtain the lychee leaf powder;

[0018] 3) Leaching: Add 5 times the volume of litchi leaf powder (ie 5 mL / g litchi leaf powder) to methanol aqueous solution with a volume fraction of 40%, extract at 80° C. for 4 hours, filter, and collect the filtrate;

[0019] 4) Organic solvent classification: Concentrate the above filtrate at 40°C to remove methanol, add 1 times its volume of water, and extract 3 times with equal volumes of petroleum ether and ethyl acetate respectively; select the ethyl acetate phase extract The concentrated extract was used for subsequent purification.

[0020] 5) Take th...

Embodiment 2

[0029] 1) Material selection: choose fresh lychee leaves, wash with water;

[0030] 2) Drying and pulverizing: drying or drying the lychee leaves, using a pulverizer to pulverize them into powder, and passing through a 120-mesh sieve to obtain the lychee leaf powder;

[0031] 3) Extraction: add lychee leaf powder to 20 times the volume (20mL / g lychee leaf powder) in an aqueous methanol solution with a volume fraction of 90%, extract at room temperature for 35 hours, filter, and collect the filtrate;

[0032] 4) Organic solvent classification: Concentrate the above-mentioned filtrate at 60°C to remove methanol, add 3 times the volume of water, and extract 12 times with equal volumes of petroleum ether and ethyl acetate respectively; select the ethyl acetate phase extract After concentration, the extract was used for subsequent purification.

[0033] Subsequent purification steps were the same as in Example 1, whereby the compound was obtained and identified as cinnamtannin B1....

Embodiment 3

[0036] 1) Material selection: choose fresh lychee leaves, wash with water;

[0037] 2) drying and crushing: dry or dry the lychee leaves, use a pulverizer to pulverize them into powder, and pass through a 60-mesh sieve to obtain the lychee leaf powder;

[0038] 3) Leaching: adding 10 times the volume (10mL / g litchi leaf powder) of litchi leaf powder to a 40% ethanol aqueous solution, extracting at 50°C for 20 hours, filtering, and collecting the filtrate;

[0039] 4) Organic solvent classification: Concentrate the above-mentioned filtrate at 60°C to remove ethanol, add 2 times the volume of water, and extract 6 times with equal volumes of petroleum ether and ethyl acetate respectively; select the ethyl acetate phase extract After concentration, the extract was used for subsequent purification.

[0040] Subsequent purification steps were the same as in Example 1, and the compound was obtained and identified as cinnamtannin B1.

[0041] The yield of cinnamtannin B1 obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com