A flat roof modular structure

A modular and flat roof technology, which is applied to roofs, roof coverings, and roofs using flexible materials, etc., can solve problems such as being easily deformed by external influences, increasing construction costs and processes, and affecting waterproof effects, etc., to avoid roofing Leakage, improved construction quality, good exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

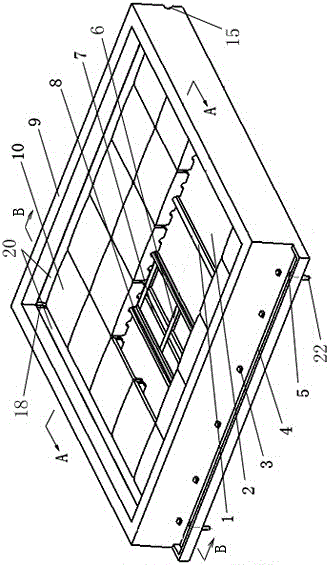

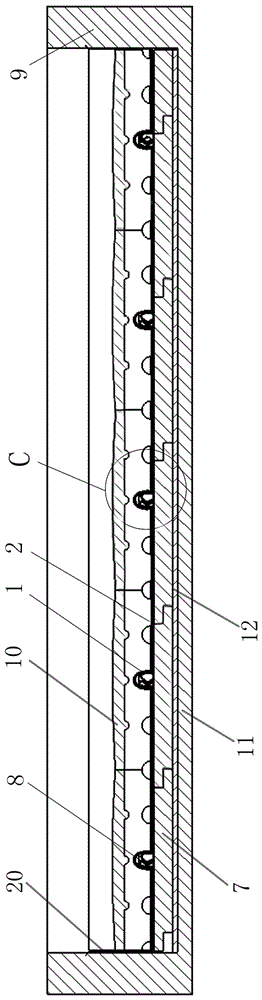

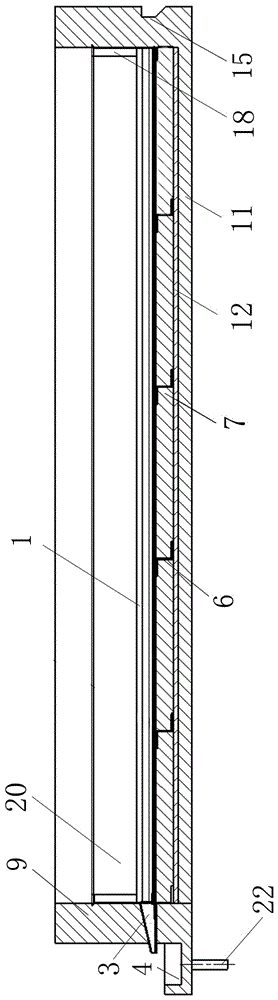

[0033] like figure 1 , 2 , 3, 4, 5, 6, 7 and 8 show a flat roof modular structure, including: a structural layer 11, a leveling layer 12 and a parapet 9 arranged around the structural layer 11, and the structural layer 11 is provided with There is a roof surface layer; the roof surface layer is provided with a waterproof system; the waterproof system is provided with several protective plates 10 that are compatible with it, and the roof surface layer is composed of a leveling layer 12, and the leveling layer 12 is perpendicular to the direction along the water There are several rows of steel seats 6 parallel to each other, and an insulation layer 7 arranged between two steel seats 6 and overlapping with the steel seats 6 is formed. The waterproof system is composed of several waterproof rolls arranged along the water direction. material clamp 8, planks 13 clamped between every two waterproof coiled material clamps 8, waterproof coiled material layer I2 above the wooden boards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com