Numerical control fuel oil combustion machine and self-inspection method thereof

A digital control, burner technology, applied in the combustion method, control combustion, burner and other directions, can solve the problems of few functions, poor safety, high failure rate, and achieve the effect of overcoming few functions, good safety, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

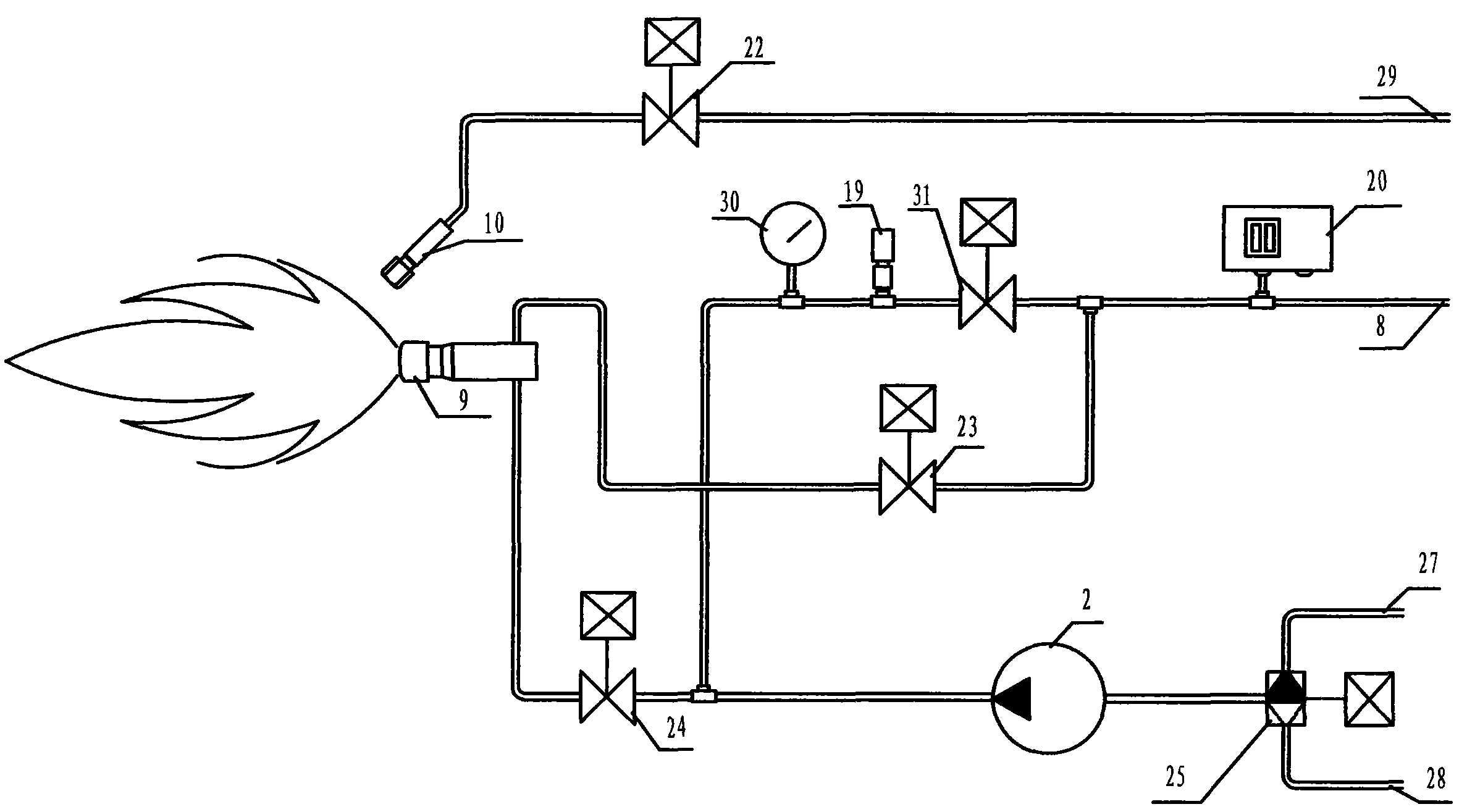

[0055] The digital control fuel burner of this embodiment includes a body, a fuel supply device, an air supply device, a fuel atomization device and an ignition device, and also includes a controller, a motor speed controller and a signal acquisition device; the fuel supply device and the air supply device They are respectively connected to the controller through their respective motor speed controllers, and the signal output terminal of the signal acquisition device is connected to the signal input terminal of the controller. The amount of fuel and the air volume sent by the air supply device.

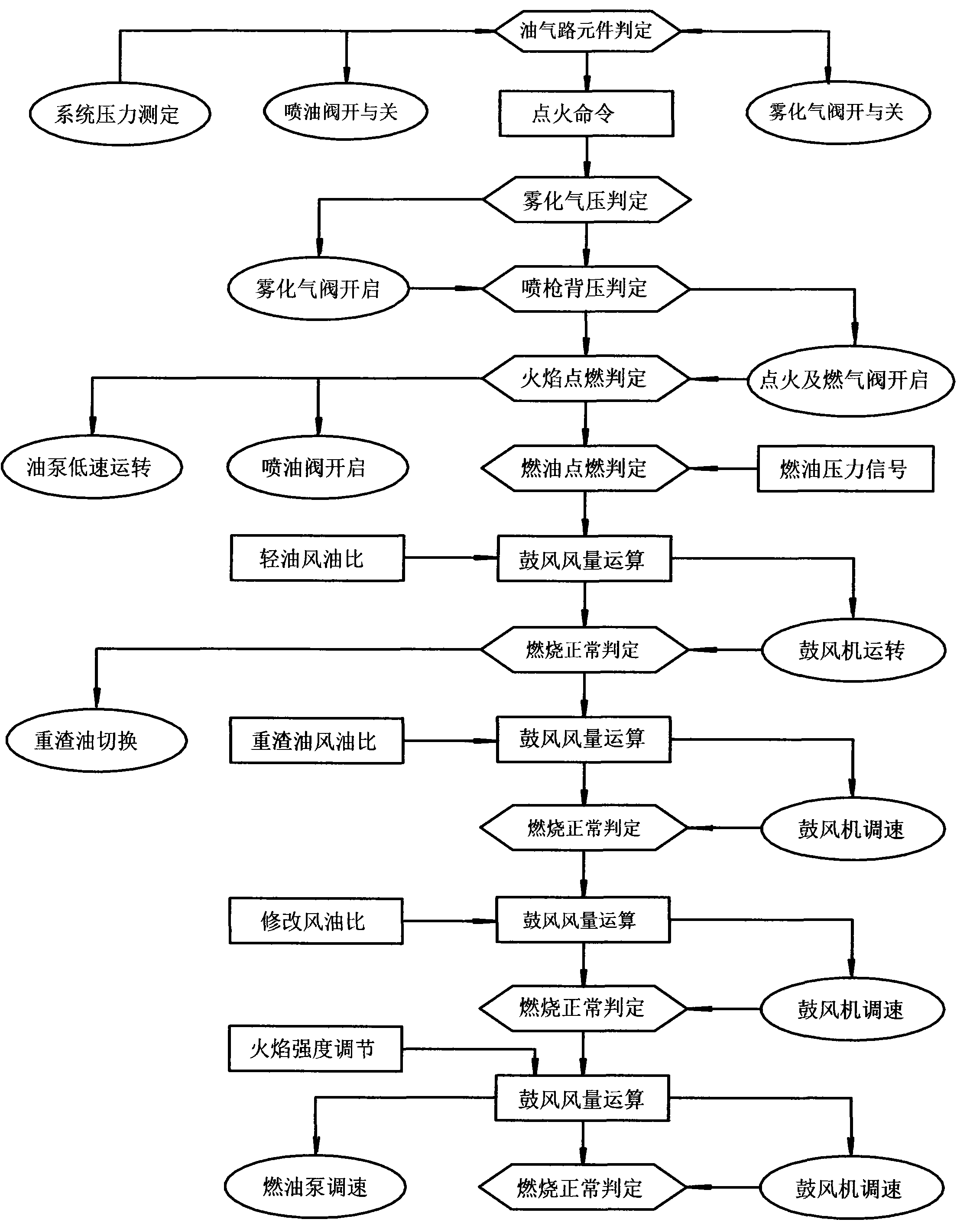

[0056] The above-mentioned controller includes a complete set of fault self-diagnosis program, which further includes:

[0057] a. The function detection program of system components before ignition is used to judge whether the functions of each valve and oil pump are normal before ignition;

[0058] b. The atomization pressure judging procedure before ignition is used to judge wheth...

Embodiment 2

[0069] The self-inspection method of the digital control fuel burner in this embodiment mainly includes the following steps:

[0070] Step 1: Before ignition, judge whether the function of each valve and oil pump is normal according to the opening of the atomizing gas valve and the fuel injection valve and the system pressure in different states;

[0071] The above-mentioned operation of judging whether the functions of each valve and oil pump are normal includes: outputting a certain amount of fuel oil from the fuel supply device to the fuel atomizing device, spraying fuel atomized steam from the fuel atomizing device, and atomizing the fuel oil by the ignition device The steam is ignited, and the air is supplied by the air supply device to assist the combustion;

[0072] If the functions of each valve and oil pump are normal, the output fuel volume and air volume are automatically and synchronously adjusted in proportion by controlling the respective motor speeds of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com