An improved limestone/lime-gypsum wet flue gas desulfurization process

A wet flue gas desulfurization and limestone technology is applied in the field of preventing the poisoning of wet desulfurization slurry and improving the limestone/lime-gypsum wet flue gas desulfurization process, which can solve the problems of easy poisoning, impure gypsum products, and low desulfurization efficiency. , to achieve the effect of reducing emission reduction capacity, eliminating poisoning accidents and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

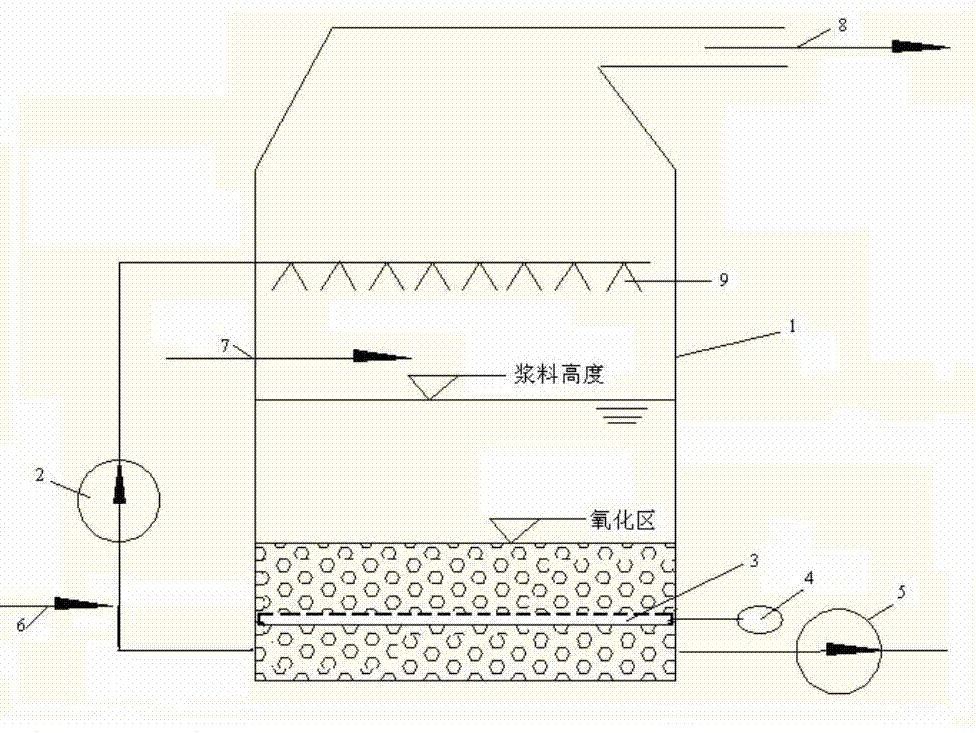

[0033] Attached figure 1 The oxidation desulfurization device shown is used for industrial production, and more than two devices can be connected in series. The main body of the oxidation desulfurization device includes an absorption tower, a circulating slurry pump and an oxidation air system. The interior of the absorption tower is mainly divided into an absorption zone and a slurry zone. During normal operation, the height of the slurry zone is 7.5m from the bottom, and the area above the height of 7.5m is the absorption zone. There is a gypsum outlet at the bottom of the slurry area, which is connected to the slurry discharge pump. The slurry area is equipped with a network-type oxidation air duct at the lower part. The oxidation air duct is preferably set within the range of 2.7 from the bottom of the slurry area. There are a large number of micropores on the surface of the oxidation air duct. The oxidation air duct is mainly used to uniformly distribute the oxidation air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com