Aerated chocolate

A chocolate and gas technology, applied in cocoa, food science, applications, etc., can solve problems such as difficult to ensure homogeneous gas mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

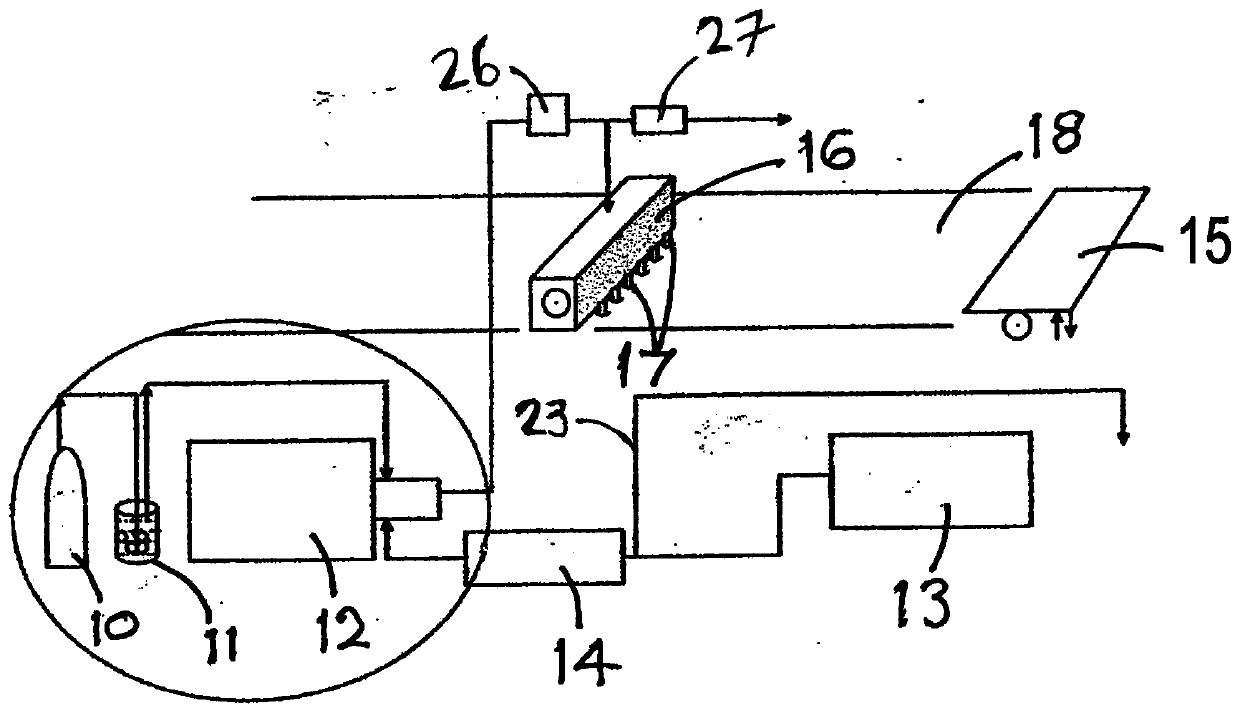

Image

Examples

Embodiment Construction

[0017] In the context of the present invention, the gas shall be food acceptable and may be air, nitrogen, nitrous oxide or carbon dioxide.

[0018] The solvent is a suitable food grade solvent. Exemplary solvents include water, glycerin, ethanol, propylene glycol, or triacetin. In certain embodiments, the solvent is selected from water, glycerol, or propylene glycol. Optionally, the solvent may contain food grade flavoring and / or coloring agents.

[0019] The solvent component may be, for example, water, glycerol or ethanol. The gas phase is bubbled through the solvent-containing device. It is possible to dissolve the dye or fragrance in a suitable solvent. The gas bubbled through the solvent system remains in gaseous form, but wetted, and if a flavored / colored solvent is used the gas is flavored / colored. A solvent content of the gas phase of about 0.2 g to about 0.8 g, preferably from about 0.3 g to 0.6 g per 100 g of the solvent component of the tempered chocolate has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com