Flexible rotary anode wet electrostatic precipitator

A technology of wet electrostatic precipitator and anode, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc. It can solve the problems that affect the self-cleaning ability of flexible electrodes, the difficulty of large-scale dust collector, and the poor uniform distribution of water film. , to achieve the effect of high dust and fog removal efficiency, no dry spots, and no channel flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

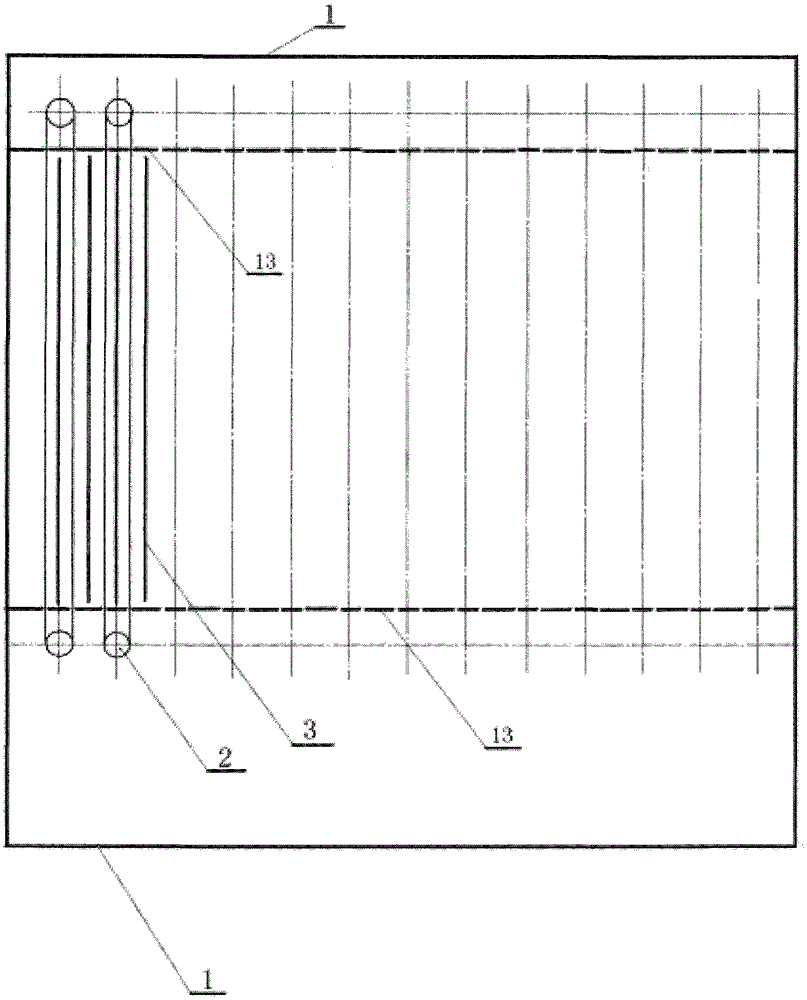

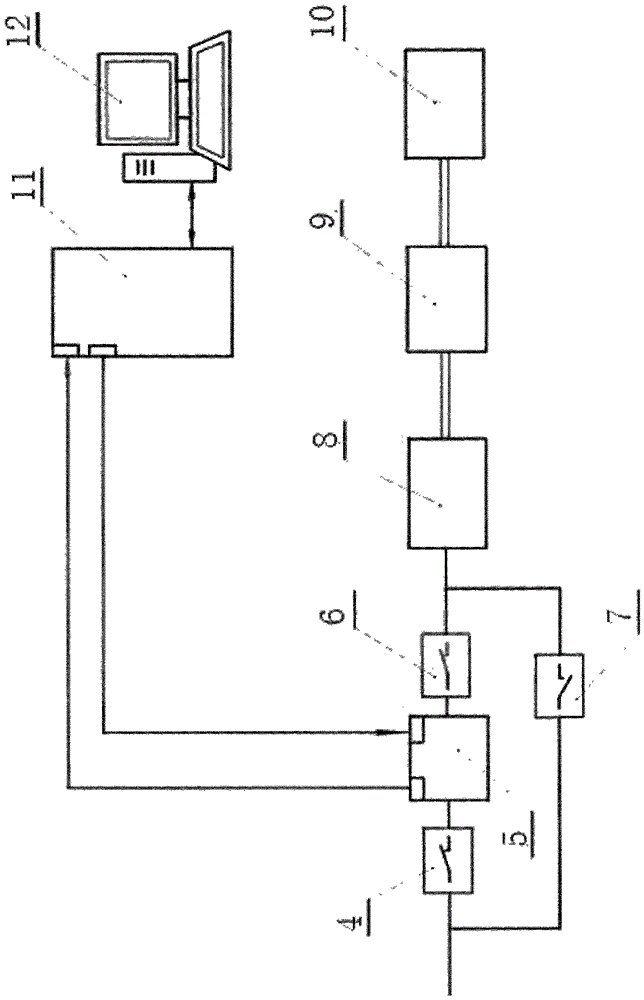

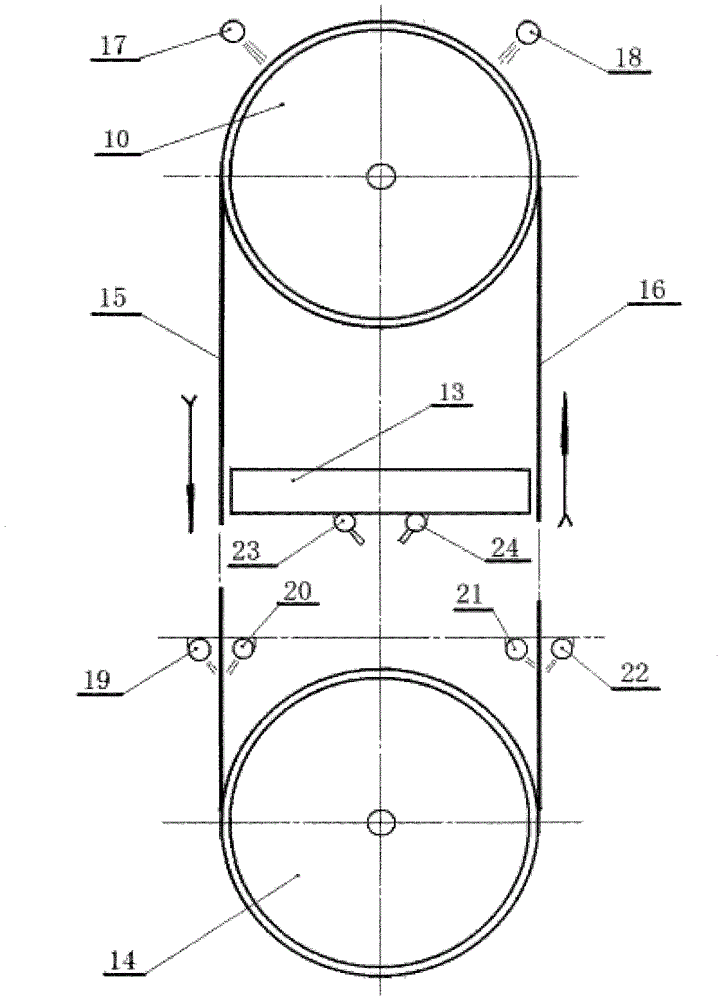

[0047] The flexible rotary anode wet electrostatic precipitator of the present invention includes a shell, an inner shell, an inlet smoke box, an air flow distribution plate, an outlet smoke box, a liquid collection tank, a flexible rotary anode system, a cathode system, a high-frequency power supply, a spray system, Cleaning system, DCS; the flexible rotary anode is made of carbon fiber and polyester filament blended fabric, ring-shaped, driven by the driving drum arranged on the upper part for low-speed rotary motion, the bearing seat of the driving drum is rooted on the upper top plate of the shell, and the driving drum is driven by a variable speed Driven by the system; the tension roller arranged at the lower part can move up and down along the guide rail to keep the flexible rotary anode with proper tension; the entire flexible rotary anode system is equipotential with the earth; the cathode wire is burr type, duplex stainless steel, Laid on the cathode frame, the cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com