Normal-pressure high-density microwave plasma shoe material surface treatment method

A technology of microwave plasma and microwave plasma, which is applied in the field of plasma shoe material surface treatment, can solve the problems of unfavorable large-scale production, low plasma density, no discovery and seeing, etc., and achieve the protection of human health, low operating cost and high effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Processing material: sole material EVA, injection molding process.

[0033] First, clean the surface of the shoe material with a cleaning agent to remove residual pollutants and other organic impurities on the surface of the shoe material (this cleaning treatment method is a conventional technology, and will not be described in detail here).

[0034] Then, the surface of the shoe material is treated with an atmospheric pressure high-density microwave plasma torch.

[0035] The processing method is as follows:

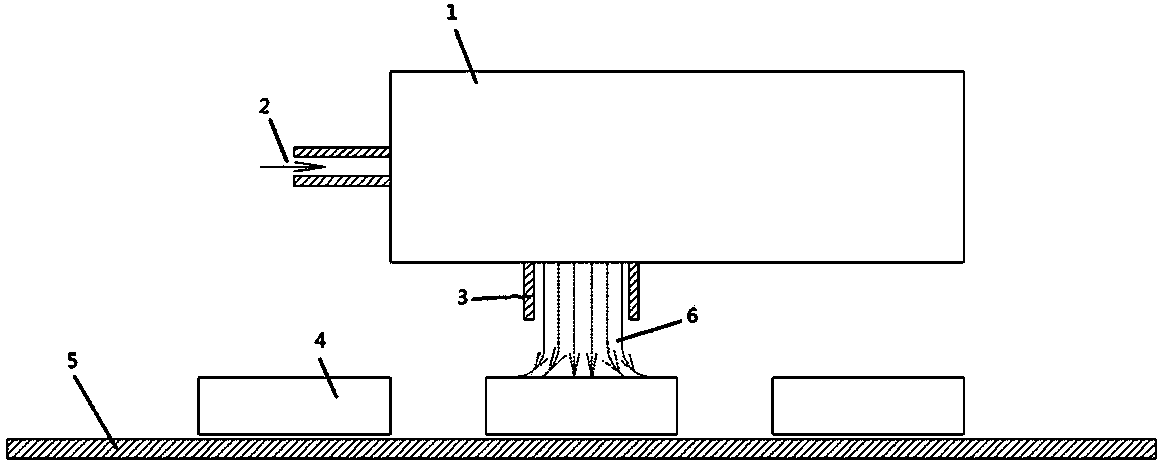

[0036] as attached figure 1 As shown, the air is sent into the high-density microwave plasma generator 1 by the air inlet 2, and is excited by microwaves to form high-density plasma, and the high-density plasma jet 6 is ejected from the plasma outlet 3, and the shoe material 4 is transported by the conveyor belt 5 Transported to the high-density plasma jet 6, the surface of the shoe material 4 is in full contact with the plasma jet 6, and a large number of acti...

Embodiment 2

[0041] Processing material: sole material EVA, molding process molding.

[0042] Treatment process: First, clean the surface of the shoe material with a cleaning agent to remove residual pollutants and other organic impurities on the surface of the shoe material (this cleaning treatment method is a conventional technology, and will not be described in detail here).

[0043] Then, the surface of the shoe material is treated with an atmospheric pressure high-density microwave plasma torch.

[0044] The processing method is as follows:

[0045] as attached figure 1 As shown, the air is sent into the high-density microwave plasma generator 1 by the air inlet 2, and is excited by microwaves to form high-density plasma, and the high-density plasma jet 6 is ejected from the plasma outlet 3, and the shoe material 4 is transported by the conveyor belt 5 Transported to the high-density plasma jet 6, the surface of the shoe material 4 is in full contact with the plasma jet 6, and a lar...

Embodiment 3

[0050] Handling Material: With sole material faux leather (gray).

[0051] First, clean the surface of the shoe material with a cleaning agent to remove residual pollutants and other organic impurities on the surface of the shoe material (this cleaning treatment method is a conventional technology, and will not be described in detail here).

[0052] Then, the surface of the shoe material is treated with an atmospheric pressure high-density microwave plasma torch.

[0053] The processing method is as follows:

[0054] as attached figure 1 As shown, the air is sent into the high-density microwave plasma generator 1 by the air inlet 2, and is excited by microwaves to form high-density plasma, and the high-density plasma jet 6 is ejected from the plasma outlet 3, and the shoe material 4 is transported by the conveyor belt 5 Transported to the high-density plasma jet 6, the surface of the shoe material 4 is in full contact with the plasma jet 6, and a large number of active groups ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com