Purification method for graphite

A technology of graphite purification and powdered graphite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost and high energy consumption, and achieve the reduction of energy consumption and cost, rapid gasification removal, The effect of improving the efficiency of graphite purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

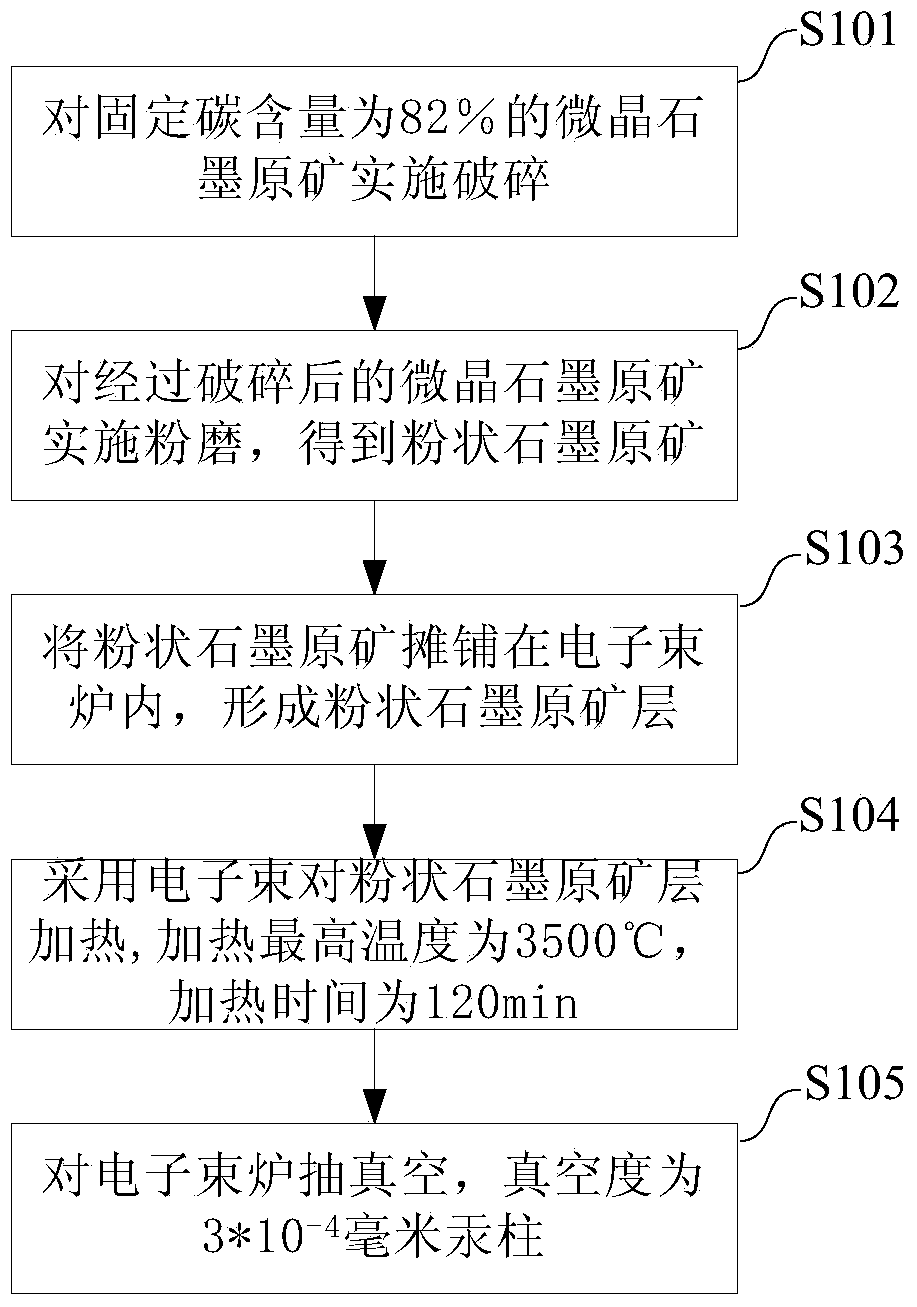

[0039] Please refer to the attached figure 1 , figure 1 The flow chart of the graphite purification method provided by Embodiment 1 of the present invention is shown.

[0040] figure 1 The process shown includes the following steps:

[0041] S101. Crushing the microcrystalline graphite raw ore with a fixed carbon content of 82%.

[0042] In the first embodiment, the raw material for graphite purification is microcrystalline graphite raw ore. Due to the large particle size of the microcrystalline graphite raw ore, in order to make the impurities in the microcrystalline graphite raw ore gasify more easily during the subsequent heating process, thereby improving the graphite purification effect, step S101 crushes the microcrystalline graphite raw ore. Crushing can reduce the particle size of microcrystalline graphite raw ore, and at the same time increase the specific surface area of microcrystalline graphite raw ore, which is conducive to the precipitation of impurity gases ...

Embodiment 2

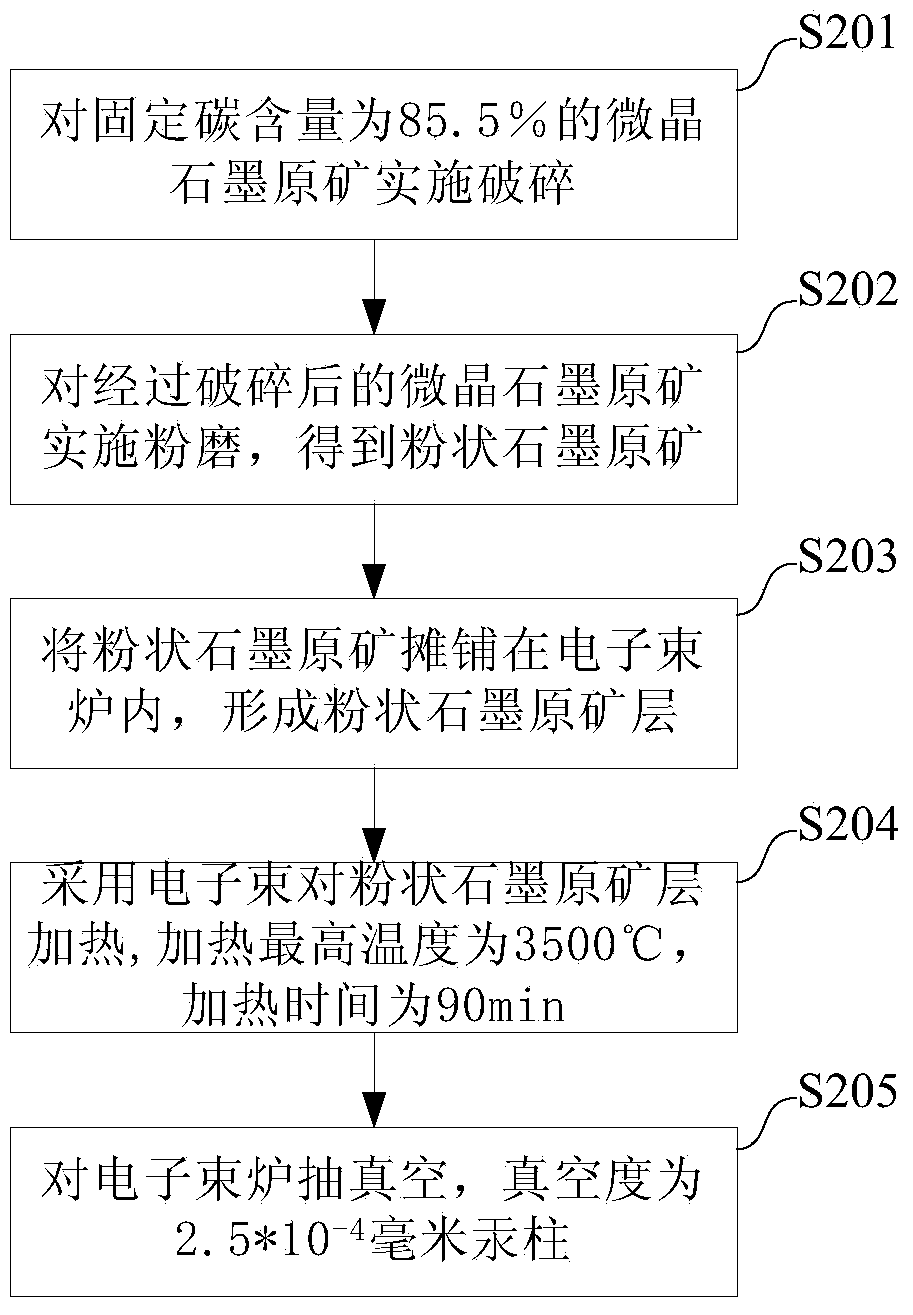

[0071] Please refer to the attached figure 2 , figure 2 The flow chart of the graphite purification method provided by Embodiment 2 of the present invention is shown.

[0072] figure 2 The process shown includes the following steps:

[0073] S201. Crushing the microcrystalline graphite raw ore with a fixed carbon content of 85.5%.

[0074] In the second embodiment, the raw material for graphite purification is microcrystalline graphite raw ore. Due to the large particle size of the microcrystalline graphite raw ore, in order to make the impurities in the microcrystalline graphite raw ore gasify more easily during the subsequent heating process, thereby improving the graphite purification effect, step S201 crushes the microcrystalline graphite raw ore. Crushing can reduce the particle size of microcrystalline graphite raw ore, and at the same time increase the specific surface area of microcrystalline graphite raw ore, which is conducive to the precipitation of impurit...

Embodiment 3

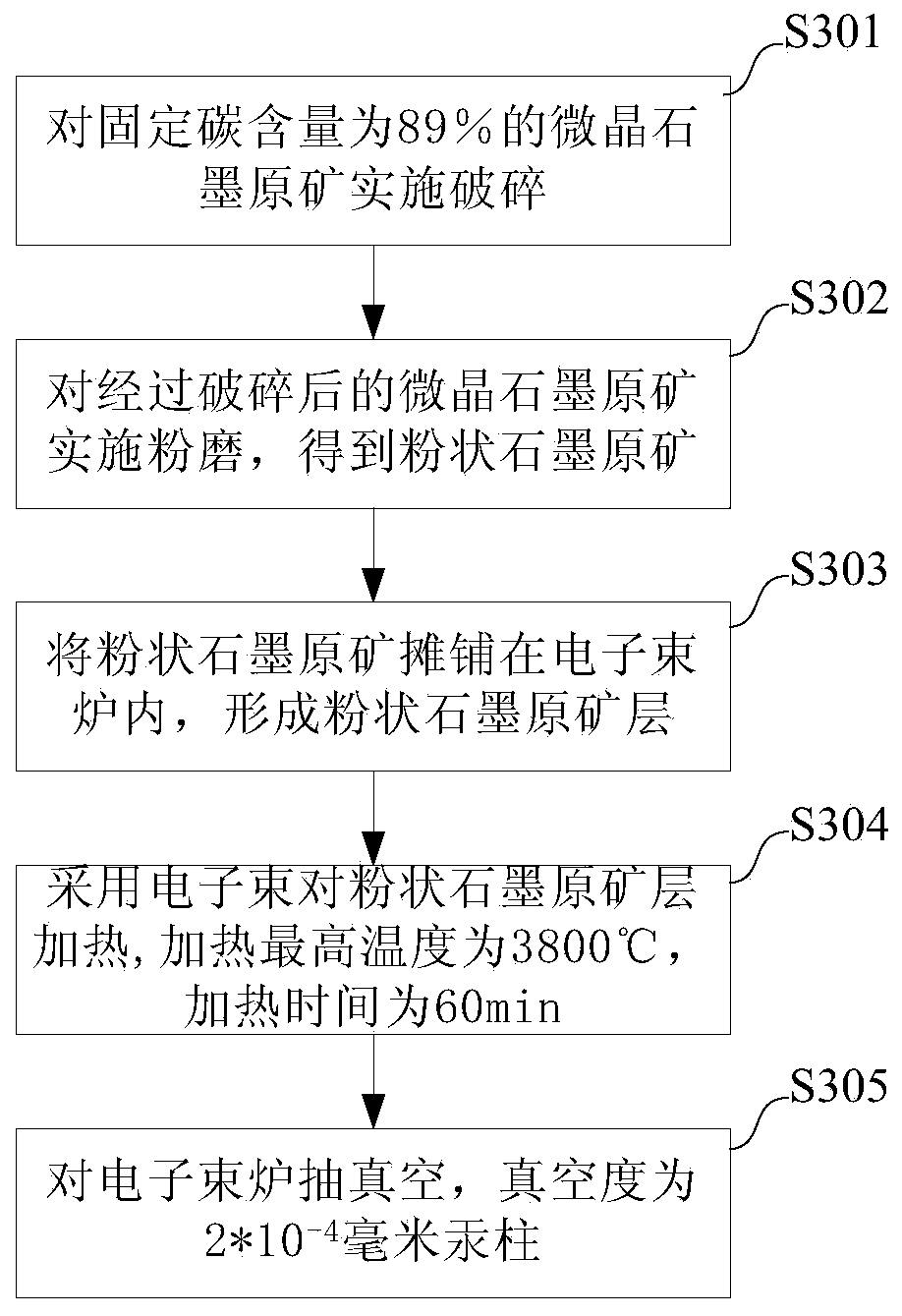

[0104] Please refer to the attached image 3 , image 3 The flow chart of the graphite purification method provided by Embodiment 3 of the present invention is shown.

[0105] image 3 The process shown includes the following steps:

[0106] S301. Crushing the microcrystalline graphite raw ore with a fixed carbon content of 89%.

[0107] In the third embodiment, the raw material for graphite purification is microcrystalline graphite raw ore. Due to the large particle size of the microcrystalline graphite raw ore, in order to make the impurities in the microcrystalline graphite raw ore gasify more easily in the subsequent heating process, thereby improving the graphite purification effect, step S301 crushes the microcrystalline graphite raw ore. Crushing can reduce the particle size of microcrystalline graphite raw ore, and at the same time increase the specific surface area of microcrystalline graphite raw ore, which is conducive to the precipitation of impurity gases du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com