Spherical nano strontium carbonate and preparation method thereof

A nano-carbonic acid, spherical technology, applied in calcium carbonate/strontium/barium, nanotechnology, nanotechnology and other directions, can solve problems such as environmental pollution, inability to produce high-quality strontium carbonate, etc., to reduce production costs, good dispersibility, preparation The effect of simple process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

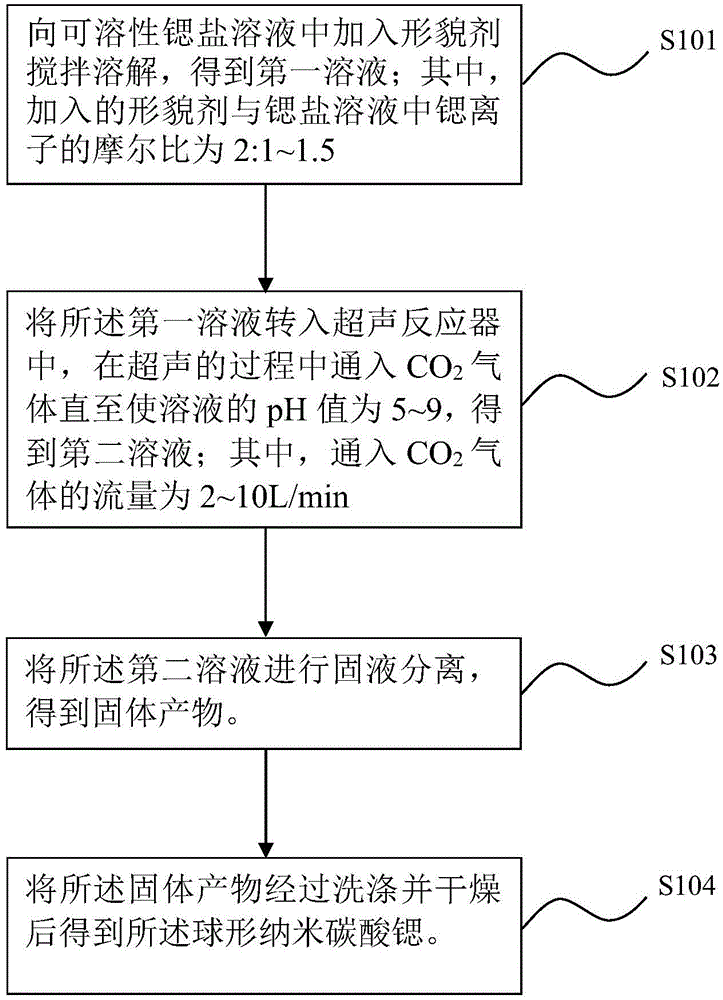

[0033] refer to figure 1 , the preparation method of the spherical nano-strontium carbonate provided in this specific embodiment comprises steps:

[0034] S101. Add a topography agent to the soluble strontium salt solution and stir to dissolve to obtain a first solution; wherein, the molar ratio of the topography agent added to strontium ions in the strontium salt solution is 2:1˜1.5. Wherein, when the morphology agent is added to the soluble strontium salt solution, the mixed solution is heated to 50-80° C., so as to speed up the dissolution time of the mixed solution and prevent the crystallization of strontium hydroxide. Wherein, the profile agent is disodium ethylenediaminetetraacetic acid (EDTA).

[0035] S102, transfer the first solution into the ultrasonic reactor, and pass CO into the ultrasonic reactor 2 Gas until the pH of the solution is 5-9 to obtain the second solution; wherein, CO 2 The gas flow rate is 2-10L / min. Among them, the CO 2 A more preferable range...

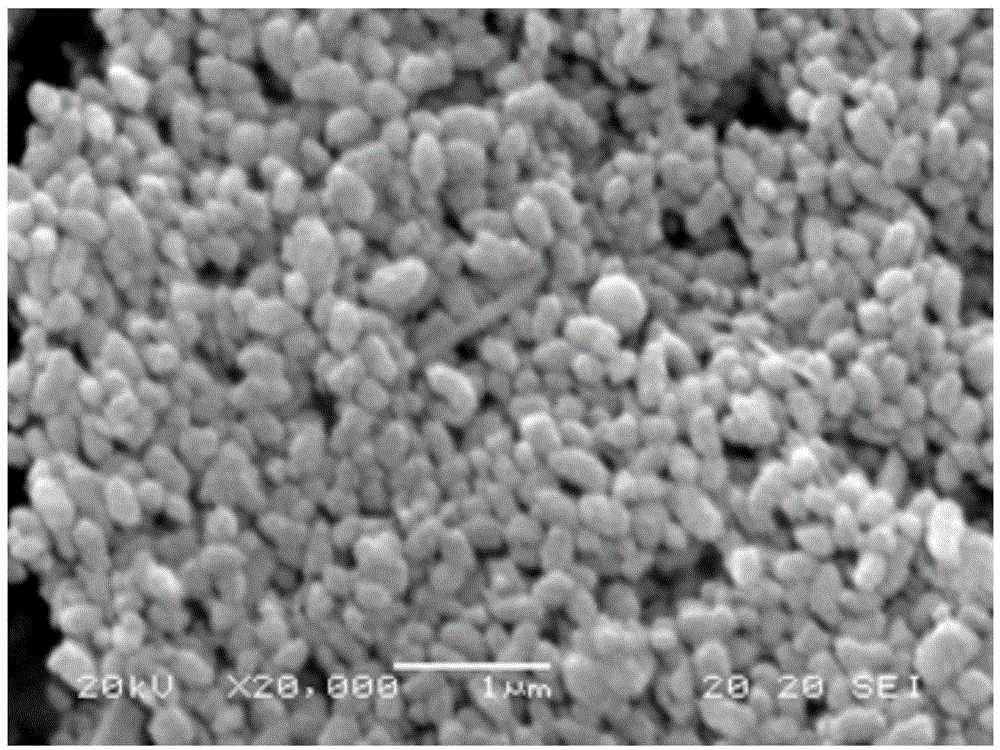

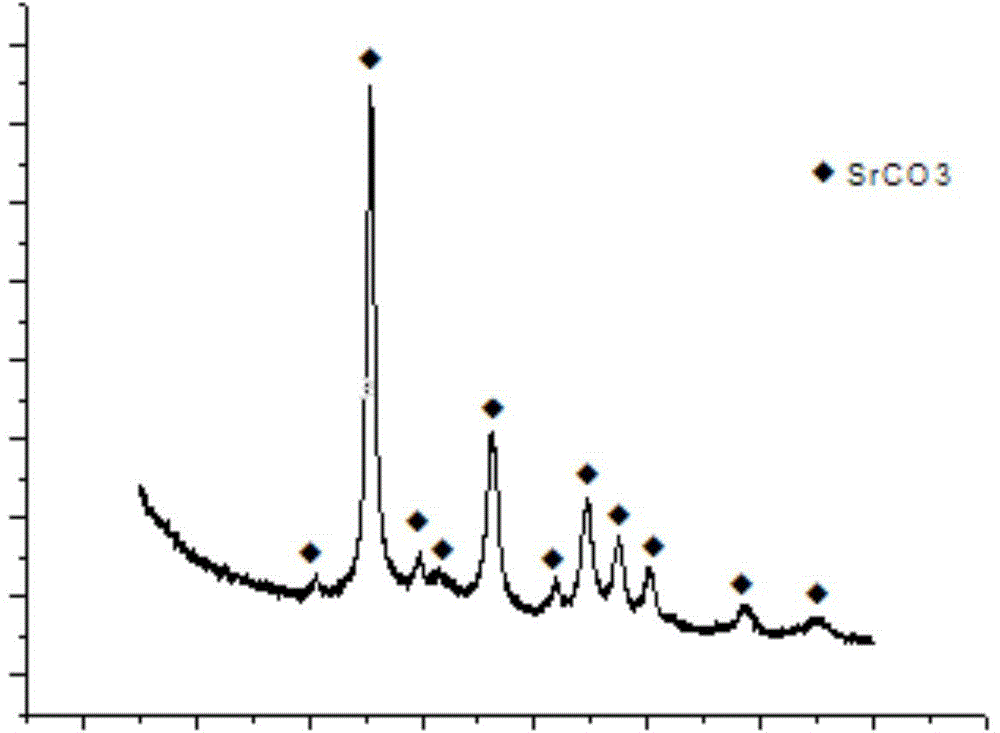

Embodiment 1

[0041] 1. Add 600ml of yellow water into a 900ml beaker, heat to 60°C, and stir to dissolve with magnetic force. After the dissolution is complete, add 200g of EDTA, continue to stir and dissolve, and obtain the raw material solution after the dissolution is complete. Among them: the molar ratio of total strontium content in yellow water (strontium sulfide, strontium hydrosulfide and strontium hydroxide) to EDTA is 2:1.

[0042] 2. Pour the obtained raw material solution into the ultrasonic reactor, the ultrasonic frequency is 100KHz, and the ultrasonic temperature is 60°C; carbon dioxide is introduced for carbonization, the flow rate of carbon dioxide is 2L / min, and the pH value of the solution is 6 after carbonization for 20 minutes, stop Carbonization gives a suspension. Wherein, the carbon dioxide gas flow also plays a stirring role during the carbonization, which can better control the morphology of the generated spherical nano-strontium carbonate.

[0043] 3. The suspen...

Embodiment 2

[0047] 1. Add 500ml of yellow water into a 900ml beaker, heat to 80°C, and stir to dissolve with magnetic force. After the dissolution is complete, add 180g of EDTA, continue to stir and dissolve, and obtain the raw material solution after the dissolution is complete. Among them: the molar ratio of the total strontium content in yellow water (strontium sulfide, strontium hydrosulfide and strontium hydroxide) to EDTA is 2:1.5.

[0048] 2. Pour the obtained raw material solution into the ultrasonic reactor, the ultrasonic frequency is 80KHz, and the ultrasonic temperature is 40°C; carbon dioxide is passed through for carbonization, the flow rate of carbon dioxide is 4L / min, and the pH value of the solution is 7 after carbonization for 13 minutes, stop Carbonization gives a suspension. Wherein, the carbon dioxide gas flow also plays a stirring role during the carbonization, which can better control the morphology of the generated spherical nano-strontium carbonate.

[0049] 3. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com