Tower-type self-circulation aerobic degradation reactor and aerobic degradation method using same

A degradation reactor and reactor technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, aerobic process treatment, etc., can solve the problem of small footprint, low aeration power requirements, and unstable effluent quality and other problems to achieve the effect of accelerating oxygen utilization, improving degradation rate and oxygen utilization rate, and rapid growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

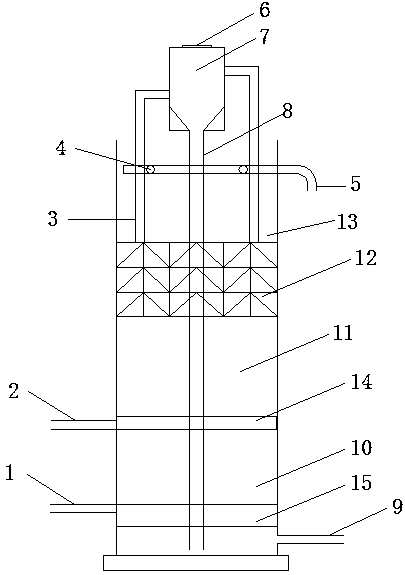

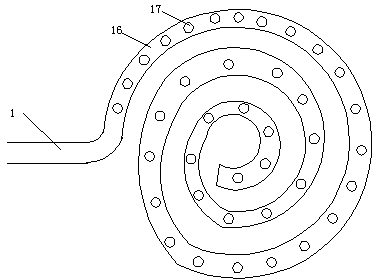

[0037] Such as figure 1 Shown: a tower-type self-circulating aerobic degradation reactor, including a reactor body, the reactor body includes an upper aerobic degradation zone 11 and a lower anoxic reaction zone 10, and the anoxic reaction zone 10 is set There is a water inlet pipe 1, a water distribution system 15 and a mud discharge pipe 9, the water distribution system 15 is a spiral coil 16, and the spiral coil 16 has a certain spiral gap, and the center of the spiral coil 16 The end is a sealed structure, and the spiral coil 16 is provided with several water outlet holes 17 with openings downward, so that the waste water is evenly distributed on the bottom surface of the reactor body and forms a vertical upflow flow state. The aerobic Between the degradation zone 11 and the anoxic reaction zone 10, the microporous aeration system 14 connected with the air inlet pipe 2 is arranged, and the microporous aeration system 14 is arranged at 4.5 meters below the water surface of ...

Embodiment 2

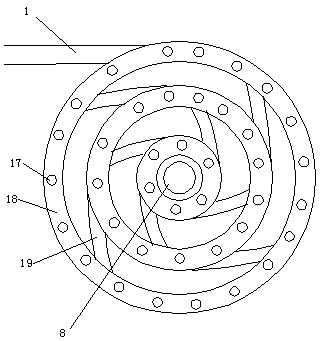

[0043] The difference between this embodiment and Embodiment 1 is that the water distribution system 15 includes a plurality of concentric water distribution rings 18, the water distribution rings 18 have several water outlet holes 17 with openings downward, and the adjacent water distribution rings The rings 18 are connected by a communication pipe 19, and the communication pipe 19 is tangent to the smaller water distribution ring of the two adjacent water distribution rings. The outermost water distribution ring 18 is connected to the water inlet pipe 1 . The central return pipe 8 passes through the innermost water distribution ring 18 .

[0044] The microporous aeration system includes a plurality of aeration layers, and each aeration layer is connected with a number of aeration heads through an aeration branch pipe, and the aeration layers are connected through communication pipes, and the communication pipes are connected to the inlet Tracheal connection. The gas-water ...

Embodiment 3

[0046] A method for performing aerobic degradation in a tower-type self-circulating aerobic degradation reactor of embodiment one or two, comprising the steps of:

[0047] 1) Inlet water: Wastewater containing organic matter is evenly distributed on the bottom surface of the reactor through the water inlet pipe and the water distribution system at the bottom of the reactor, and is evenly mixed with the sludge digestion liquid in the anoxic reaction zone to form a vertical upflow flow At the same time, the macromolecular organic matter in the wastewater is hydrolyzed and acidified into small molecules, the nitrate nitrogen in the digestive juice undergoes denitrification biological denitrification reaction, and the phosphorus accumulation bacteria release phosphorus. The sludge concentration in the anoxic reaction zone is 15000-20000mg / L;

[0048] 2) Aeration and oxygen supply: The sludge and wastewater mixture after the anoxic reaction rises to the aeration system. The resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com