A fluorescent functional polymer nanosphere with dual response to temperature and pH, preparation method and application

A nano-microsphere and dual-response technology, which is applied in chemical instruments and methods, thermometers, fluorescence/phosphorescence, etc., can solve the problems of applicability limitations, deterioration of fluorescence performance, etc., and achieve the effect of good response function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

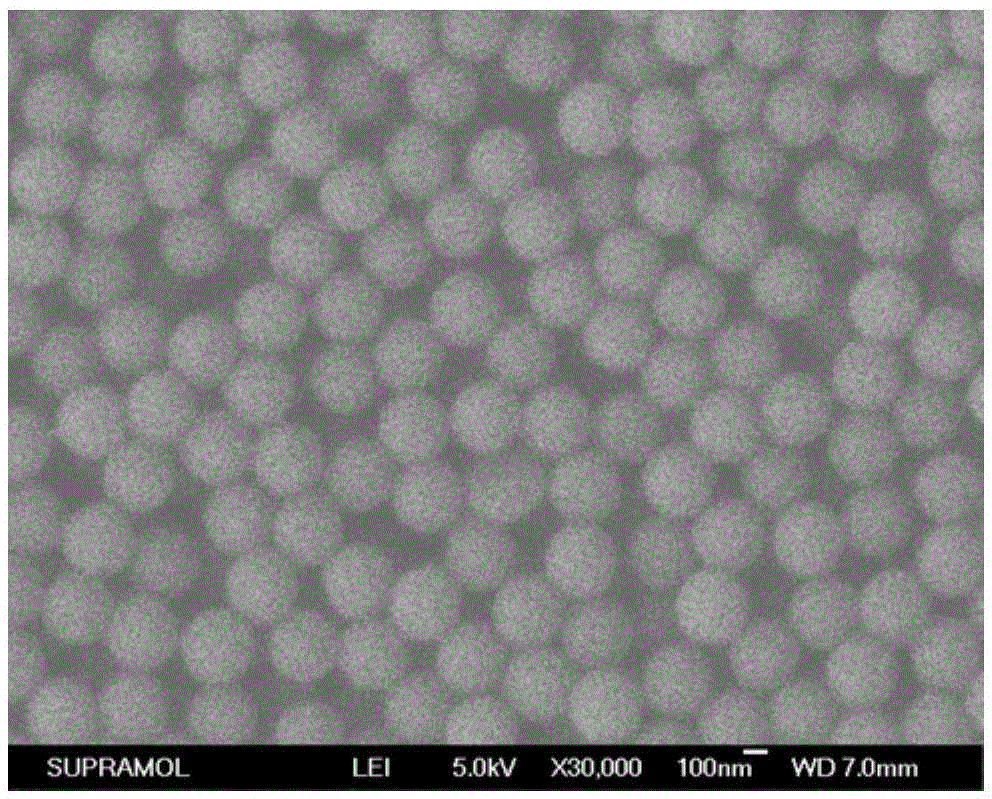

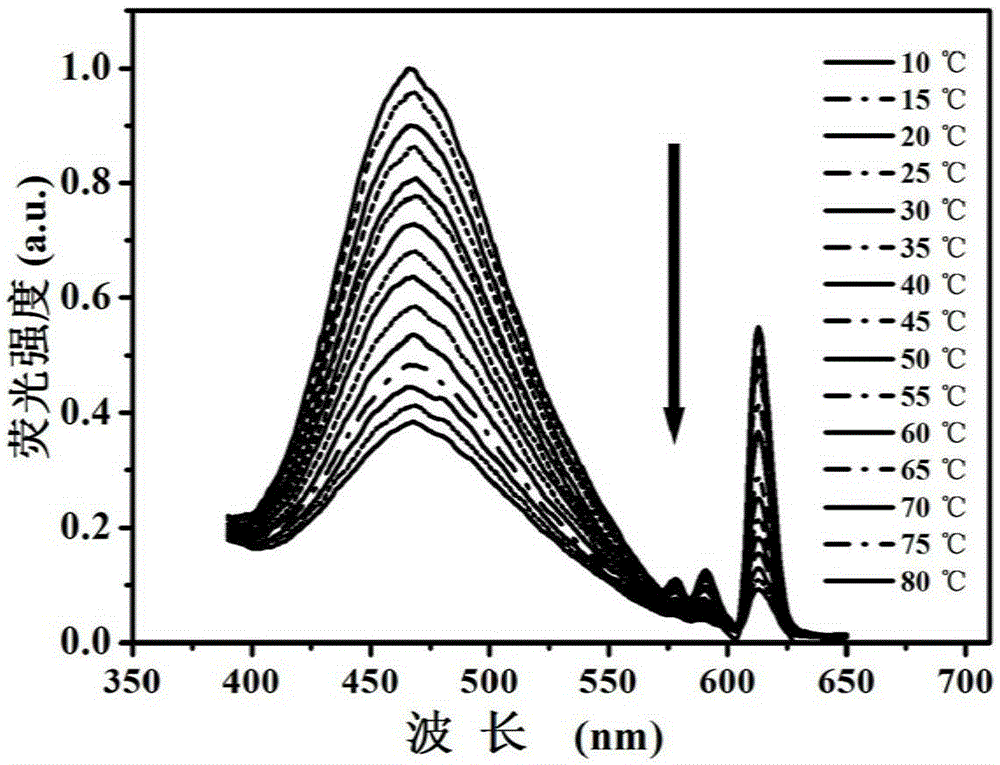

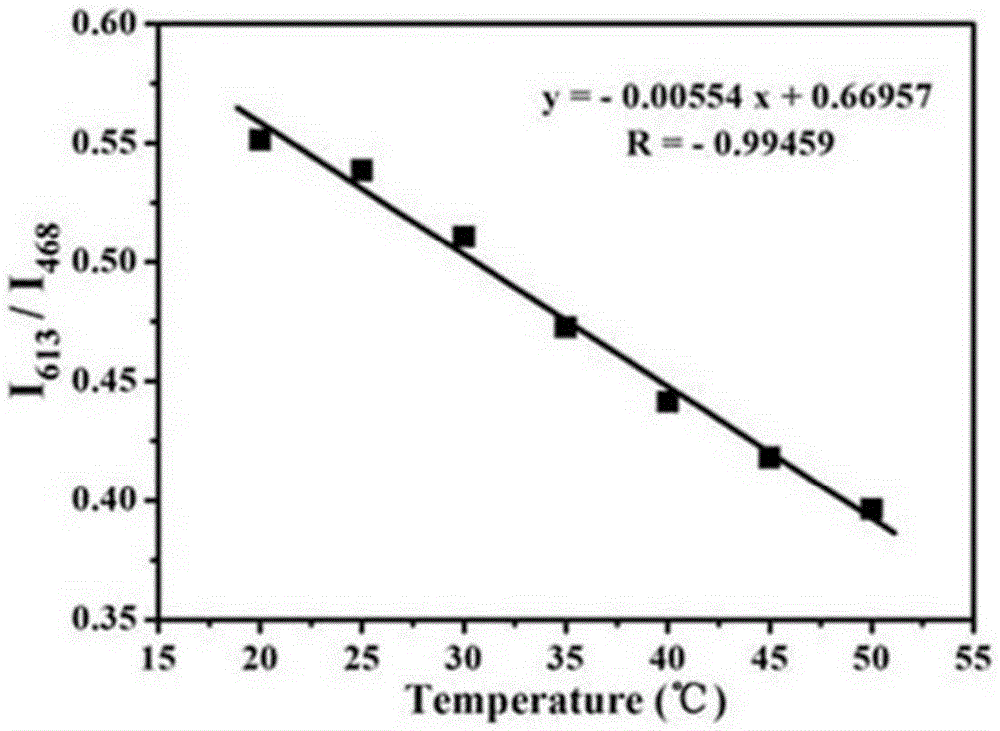

[0023] (1) Weigh 4.42mmol of NIPAM monomer and dissolve it in 185mL deionized water, add it to a 500mL three-necked bottle, add 1.4×10 -6 mol of rare earth complex Eu(TTA) 3Phen, 5mL of styrene (St), at room temperature and under nitrogen protection, mechanically stirred (400rpm) for 30min, then gradually warmed up to 70°C, added 15mL of an aqueous solution containing 0.3mmol of initiator potassium persulfate (KPS) in the system, and initiated polymerization. The reaction was carried out for 12h to end. The resulting Eu(TTA) 3 Phen's seed polymer microspheres are centrifuged at high speed to remove impurities such as unpolymerized monomers and initiators in the liquid phase, and the product is dissolved in 100mL of deionized water for use.

[0024] (2) the polymer microsphere that step (1) is obtained continues to carry out seed emulsion polymerization, adds 40mmolNIPAM in the polymer seed microsphere solution that step (1) obtains, the AA of 3mmol, under room temperature a...

Embodiment 2

[0027] (1) Weigh 5 mmol of VCL monomer and dissolve it in 190 mL of deionized water, add it to a 500 mL three-necked bottle, add 2×10 -6 mol of RhB, 5mL of styrene (St), under the protection of nitrogen at room temperature, mechanically stir (400rpm) for 30min, gradually warm up to 70°C, add 10mL of an aqueous solution containing 0.3mmol of initiator ammonium persulfate (APS) into the system , triggering polymerization. The reaction was carried out for 12h to end. The obtained RhB-containing polymer seed microspheres. Impurities such as unpolymerized monomers and initiators in the liquid phase were removed by high-speed centrifugation, and the product was dissolved in 100 mL of deionized water for use.

[0028] (2) The polymer microsphere that step (1) is obtained continues to carry out seed emulsion polymerization, adds 40mmolVCL, the MAA of 3.2mmol in the polymer seed microsphere solution that step (1) obtains, under nitrogen protection at room temperature, mechanical Sti...

Embodiment 3

[0031] (1) Weigh 5 mmol of NVC monomer and dissolve it in 100 mL of deionized water, add it to a 500 mL three-necked bottle, add 1.5×10 -6 mol of CdTe, 5mL of fluorostyrene (F-St), under the protection of nitrogen at room temperature, mechanically stirred (400rpm) for 30min to remove the air in the system, then gradually raised the temperature to 70°C, added 10mL of initiator containing Sodium Sulfate (Na 2 S 2 o 8 ) 0.3mmol aqueous solution in the system to initiate polymerization. The reaction was carried out under nitrogen protection for 12h to end. CdTe-containing polymer seed microspheres were obtained. Impurities such as unpolymerized monomers and initiators in the liquid phase were removed by high-speed centrifugation, and the product was dissolved in 100 mL of deionized water for use.

[0032] (2) The polymer microspheres that step (1) obtains is continued to carry out seed emulsion polymerization, adds 45mmolNVC, the MAA of 3.5mmol in the polymer seed microsphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com