Composition for flame-retardant conveying belt and flame-retardant conveying belt

A technology of flame retardancy and composition, which is applied in the field of preparation of flame-retardant conveyor belts, can solve the problems of short service life, layered foaming, surface scalding, etc., to reduce production costs, not easy to slide, prevent scalding and burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A composition for a flame-retardant conveyor belt, which has the following components in parts by weight: natural rubber 15, styrene-butadiene rubber 85, butadiene rubber 10, nano-zinc oxide 6, anti-aging agent 3.5, carbon black 55 , dispersant 3, sulfur 2, vulcanization accelerator 3 and flame retardant 30; wherein, the flame retardant is a composition composed of bromotriazine 13, antimony trioxide 2, zinc borate 0.8, and melamine cyanurate MCA2.

[0025] The anti-aging agent is a mixture of anti-aging agent AW and anti-aging agent BLE in a mass ratio of 1:1. The structural formulas of anti-aging agent AW and anti-aging agent BLE are as follows: The dispersant is STRUKTOL EF44 provided by Jiatuo (Shanghai) Chemical Trading Co., Ltd., and the vulcanization accelerator is a compound of vulcanization accelerator TBBS and vulcanization accelerator DM at a mass ratio of 2.2:0.2.

[0026] Proportion the above-mentioned composition, follow the steps below to prepare the fil...

Embodiment 2

[0031] A composition for a flame-retardant conveyor belt, which has the following components in parts by weight: 10 natural rubber, 78 styrene-butadiene rubber, 12 butadiene rubber, 6 nanometer zinc oxide, 4 antioxidants, and 60 carbon black , dispersant 3.5, sulfur 2, vulcanization accelerator 2.5 and flame retardant 28; wherein, the flame retardant is a composition composed of bromotriazine 14, antimony trioxide 2, zinc borate 1, melamine cyanurate MCA2, and the rest The components and film preparation method are the same as in Example 1.

[0032] Test items

[0033] The flame retardant performance test is carried out according to UL94, and the test equipment is the HVUL2 horizontal vertical combustion instrument of ATLAS Company of the United States.

Embodiment 3

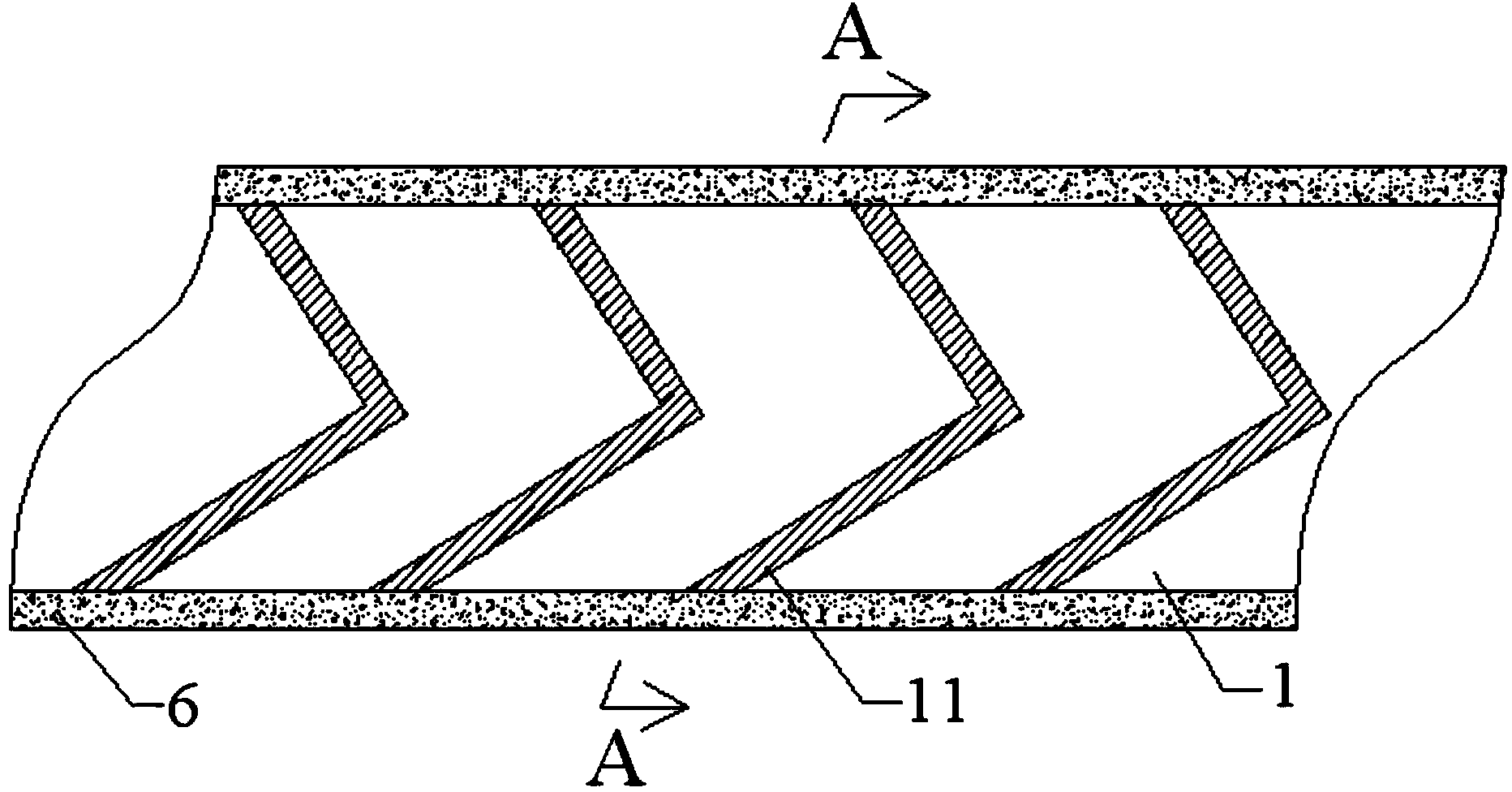

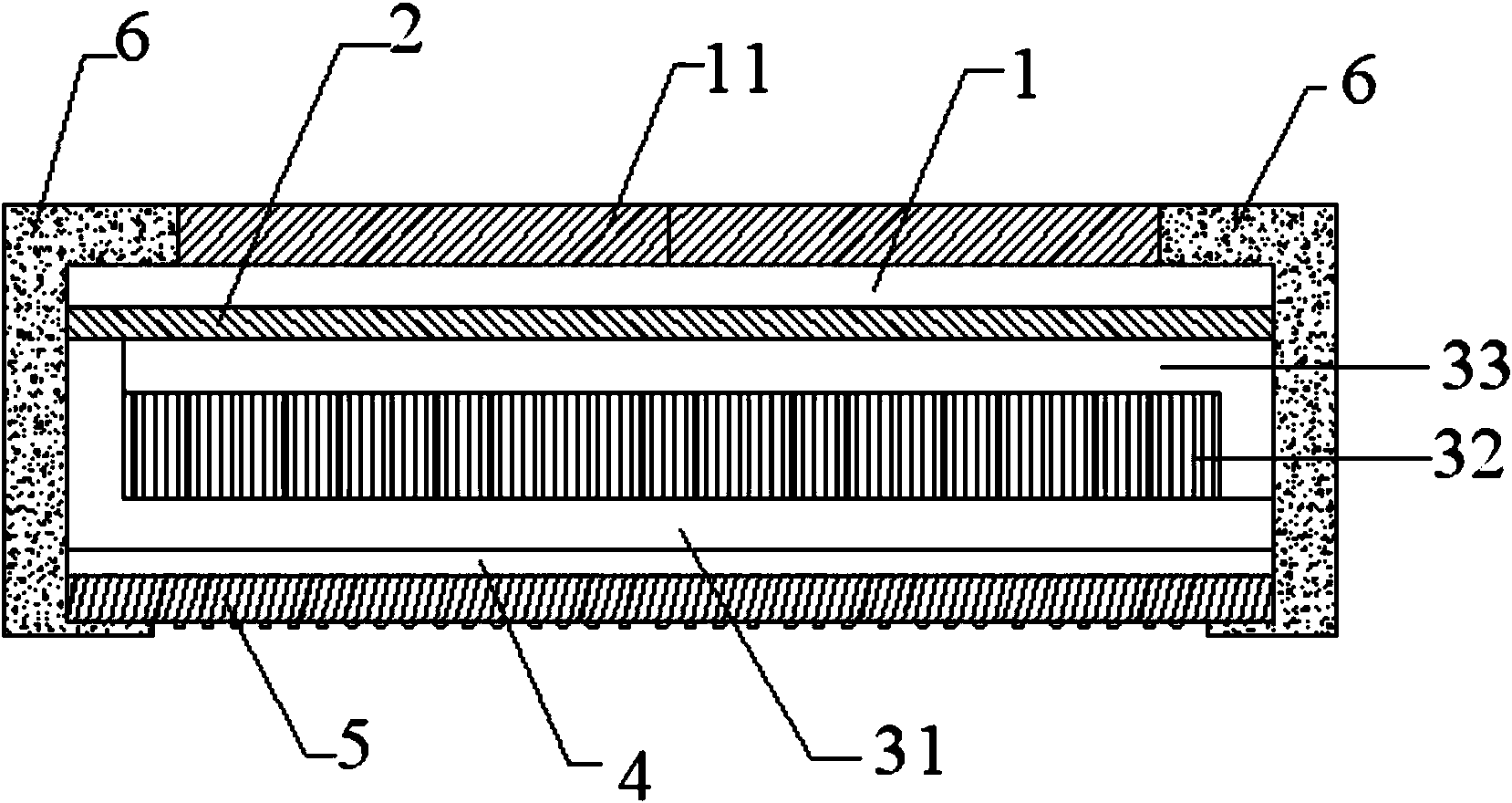

[0035] as attached figure 1 , 2Shown is a flame-retardant conveyor belt prepared by using the flame-retardant glue obtained from the formula of Example 1. The structure of the conveyor belt includes from top to bottom: a first flame-retardant layer 1, a first aluminum foil layer 2, a core layer, the second aluminum foil layer 4, the second flame-retardant layer 5, and the two opposite sides of the conveyor belt are respectively symmetrically provided with "[]" hemming structures 6; the core layer is made of "L"-shaped fiberglass fabric 31 , chopped carbon fiber 32, "7" type glass fiber fabric 33 and flame retardant glue four composites, chopped carbon fiber 32 and the bottom edge of "L" type glass fiber fabric 31, "7" type glass fiber fabric The upper edge of 33 is vertical, and " L " type glass fiber fabric 31 is woven by the triaxial glass fiber silk of 0 °, 45 ° and 90 ° through polyester silk, and " 7 " type glass fiber fabric 33 is formed by -90 °, 0 ° ° and 90° triaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com