Light-duty modified asphalt

A modified asphalt and light-load technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of waste and high cost of colored asphalt, and achieve the effect of cheap price, bright color and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A light-load modified asphalt is prepared according to the following steps:

[0026] Raw materials: 34 parts of petroleum resin, 28 parts of rubber operating oil, 6 parts of thermoplastic styrene-butadiene rubber (SBS), 8 parts of low-density polyethylene (LDPE), 0.01 part of dioctyl phthalate (DOP), 0.02 parts of polystyrene Ethylene wax is prepared as raw material, in parts by weight; the petroleum resins are C9 resin, coumarone resin and C5 resin with a mass ratio of 1.5:5:2.

[0027] (1). Preparation of prepolymer

[0028] Mix the above-mentioned petroleum resin, rubber process oil, LDPE, DOP and polyethylene wax in the crucible first, put the crucible into an oil bath device with a temperature control of 155°C to 165°C, melt and stir until there are no large particles, Enter the shearing machine, cut at 5000r / min for 10-15min to obtain the prepolymer;

[0029] (2). Preparation of light-load modified asphalt

[0030] Add SBS gradually to the prepared prepolymer, ...

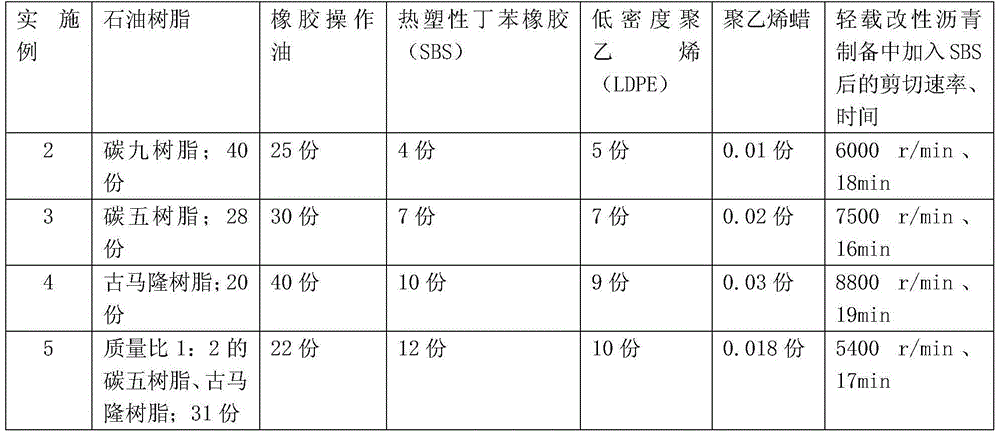

Embodiment 2~5

[0032] Carry out according to following raw material, processing parameter, other are all identical with embodiment 1.

[0033]

[0034] The above light-load modified asphalt, according to 70# base asphalt as the standard, penetration: 60-80, softening point: >45°C, ductility (10°C, 15°C) >100CM, dynamic viscosity of asphalt at 135°C meets <3Pa. s. According to the standard chromaticity card, the chromaticity of the light-load modified asphalt of the present invention is relatively light, and the chromaticity ranges from 14 to 17, belonging to the light yellow system. The light color is easy to change the color, easy to mix with more color colorants, and the output color is bright. It is clearly pointed out in the road asphalt specification that the rotational viscosity of modified asphalt at 135°C is less than 3Pa.s, and the light-load modified asphalt of the present invention has a viscosity of 2.58Pa.s at 135°C. The smaller viscosity is easy to construct.

[0035] Accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com