Production method of low-EC (ethyl carbamate) Shaoxing wine

A production method and technology of Shaoxing wine, which is applied in the field of food processing, can solve the problems of violating traditional crafts, yellow rice wine cannot be called Shaoxing wine, and damage the traditional flavor of Shaoxing wine, and achieve the effect of simple and effective production method and reducing EC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

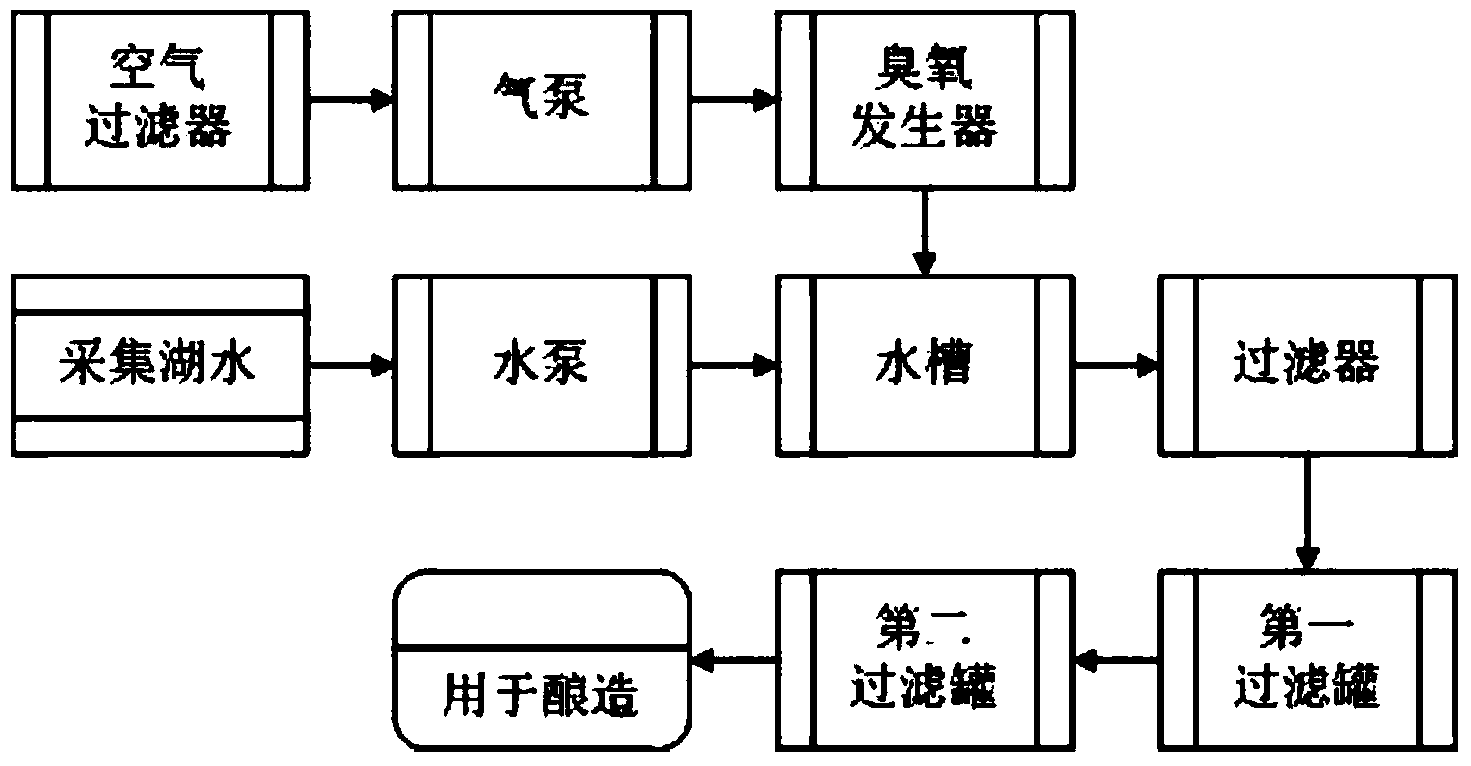

[0024] 10-15 days before the beginning of winter in the lunar calendar, the water from Baijia Lake in the upper reaches of Jianhu Lake is drawn and stored in the water storage tank. A zeolite aeration plate is arranged for each square decimeter at the bottom of the water storage tank. All the aeration plates are connected to an ozone generator through pipelines. connect. The ventilation rate of the ozone generator is set so that the ozone concentration remains at 0.15-0.25ppm under 1 standard atmospheric pressure; ozone.

[0025] After the introduction of ozone is completed, let the water in the tank stand for 12 hours, and install a filter at the outlet of the tank to ensure that the water is clear. The above-mentioned clarified water is passed through the first filter tank filled with KDF55 with a particle size of 20-50 mesh, and then through the second filter tank filled with ceramsite with a particle size of 2.5-3 cm. The inner diameter of the filter tank is 30cm, the le...

Embodiment 2

[0030] Extract Jianhu water and store it in the water storage tank. An aeration plate made of zeolite is arranged on each square decimeter at the bottom of the water storage tank. All aeration plates are connected to an ozone generator through pipelines. The ventilation rate of the ozone generator is set so that the ozone concentration is maintained at 0.20-0.30 ppm at 1 standard atmospheric pressure. In this embodiment, the time for introducing ozone is 40 minutes, and 1.0 cubic meters of ozone is introduced per cubic meter of water.

[0031] After the introduction of ozone is completed, let the water in the tank stand still for 36 hours, and install filter cotton at the water outlet of the tank to ensure that the water body is clear. The above-mentioned clarified water is passed through a filter tank filled with a particle size of 20-50 mesh KDF55, and then through a filter tank filled with a particle size of 2.5-3cm ceramsite. The inner diameter of the filter tank is 30cm,...

Embodiment 3

[0036] Extract Jianhu water and store it in the water storage tank. An aeration plate made of zeolite is arranged on each square decimeter at the bottom of the water storage tank. All aeration plates are connected to an ozone generator through pipelines. The ventilation rate of the ozone generator is set so that the ozone concentration is maintained at 0.20-0.30 ppm at 1 standard atmospheric pressure. In the present embodiment, the time for introducing ozone is 50 minutes, and 0.5 cubic meters of ozone is introduced per cubic meter of water.

[0037]After the introduction of ozone is completed, let the water in the tank stand for 24 hours, and install filter cotton at the water outlet of the tank to ensure that the water body is clear. The above-mentioned clarified water is passed through a filter tank filled with a particle size of 20-50 mesh KDF55, and then through a filter tank filled with a particle size of 2.5-3cm ceramsite. The inner diameter of the filter tank is 30cm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com