Automotive frame steel with yield strength of higher than 700 MPa and manufacturing method thereof

An automobile beam and yield strength technology, applied in the field of steel rolling, can solve the problems of affecting the stamping performance, affecting the transverse bending performance, restricting the application of automobile beam plates, etc., so as to achieve the effect of improving the transverse bending performance and improving the plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] A steel for automobile beams with a yield strength of more than 700MPa provided by the present invention comprises the following chemical components in mass percentage: carbon: 0.05-0.12%; silicon: 0.08-0.20%; manganese: 1.20-2.10%; niobium: 0.03-0.06% ; Titanium: 0.06~0.20%; Molybdenum: ≤0.25%; Chromium: 0.35~0.55%; Phosphorus: ≤0.020%; Sulfur: ≤0.008%; : ≤0.003%; [N]: ≤0.005%; others are iron and unavoidable trace impurities.

[0025] Among them, although carbon no longer plays a major role in solid solution strengthening in steel, it still significantly affects each phase transformation process, controls the final formed structure, and roughly determines the corresponding mechanical properties of the structure. Carbon can significantly improve the strength of steel, but too high carbon is not good for the toughness of steel. Therefore, in order to improve the cold formability of steel for automobile frame, the content of carbon should be controlled below 0.12%. The ...

Embodiment approach 2

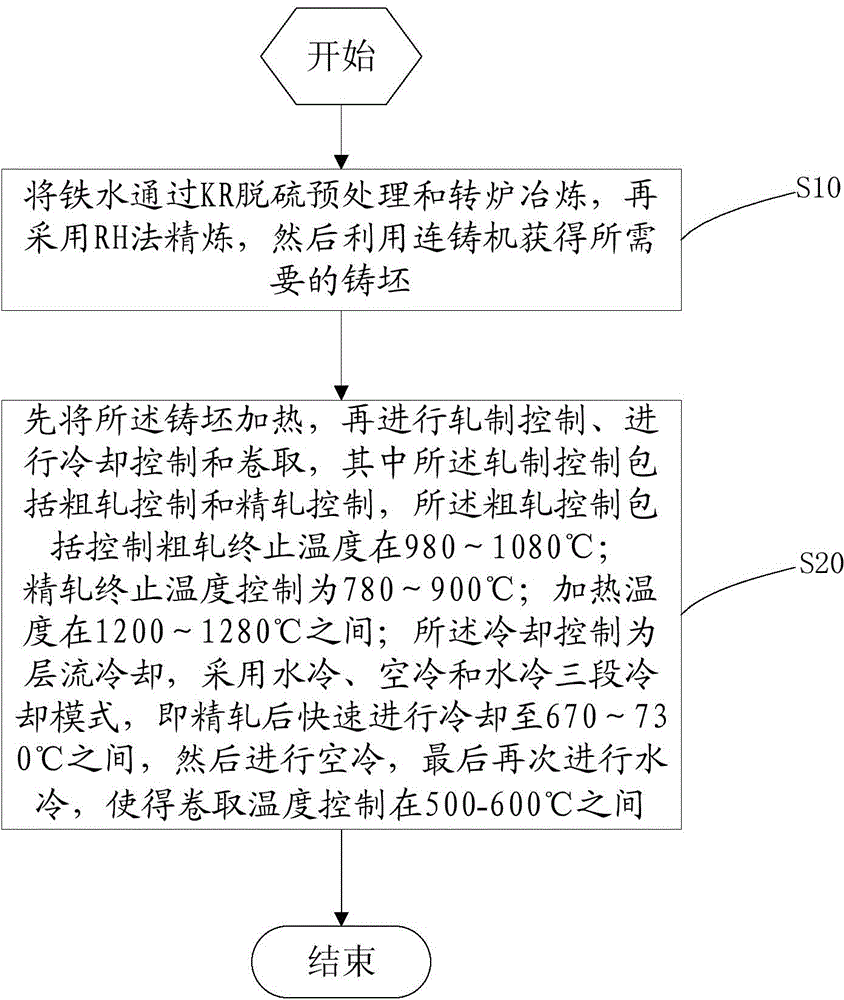

[0035] Such as figure 1 as shown, figure 1 It is a schematic flowchart of a method for manufacturing hot-formed steel with high bending resistance for automobiles provided by Embodiment 1 of the present invention.

[0036] Step S10: the molten iron is subjected to KR desulfurization pretreatment and converter smelting, and then RH method is used for refining, and then a continuous casting machine is used to obtain the required slab. In this example, the molten iron is passed through the KR desulfurization pretreatment and the full three desulfurization converter smelting process to control the content of harmful elements such as sulfur and phosphorus in the molten steel, and is refined by the RH method in order to accurately control the chemical components in the molten steel content, and then use the continuous casting machine to obtain the required slab.

[0037] The cast slab obtained by the above method has the following chemical composition in mass percentage: carbon: 0...

Embodiment approach 3

[0041] A steel for automobile beams with a yield strength above 700MPa, the chemical composition of the billet is recorded as carbon: 0.072%; silicon: 0.03%; manganese: 1.50wt%; niobium: 0.052wt%; titanium: 0.089wt%; chromium: 0.45 wt%; phosphorus: 0.013wt%; sulfur: 0.0042wt%; aluminum: 0.035wt%; calcium: 0.0012wt%; [O]: 0.0020wt%; Trace impurities.

[0042] (1) Stir the molten iron by the KR method so that the sulfur content is roughly reduced to 16ppm.

[0043] (2) Low-sulfur steel scrap is used for smelting in the converter, and lime and fluorite are added in the tapping process of the converter, so that the sulfur content of the molten steel is roughly controlled at 55ppm.

[0044] (3) Subsequently, the sulfur content of molten steel refined by the RH method is roughly controlled at 42ppm.

[0045] (4) Put the slab with a thickness of 230mm and a temperature of 540°C into the heating furnace for heating. The slab is heated in the furnace for 235 minutes, of which the soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com