Engine oil pin position sensor detecting circuit

A technology for detecting circuit and engine oil, which is applied in the direction of transmitting sensing components, instruments, measuring devices, etc. by using electric/magnetic devices, can solve the problems of incompetence in engine oil needle detection, etc., and achieve strong anti-interference ability, novel structure, Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

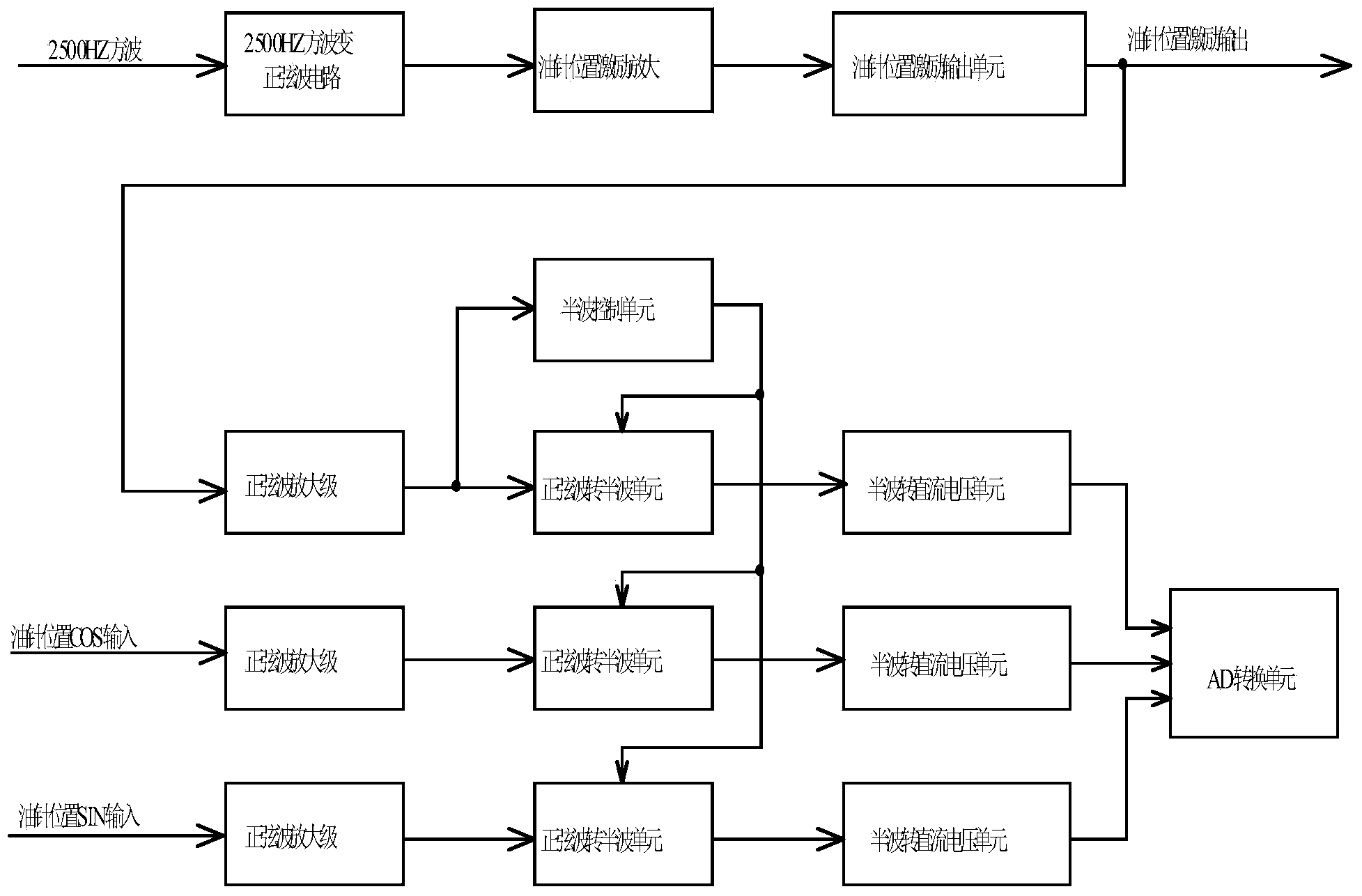

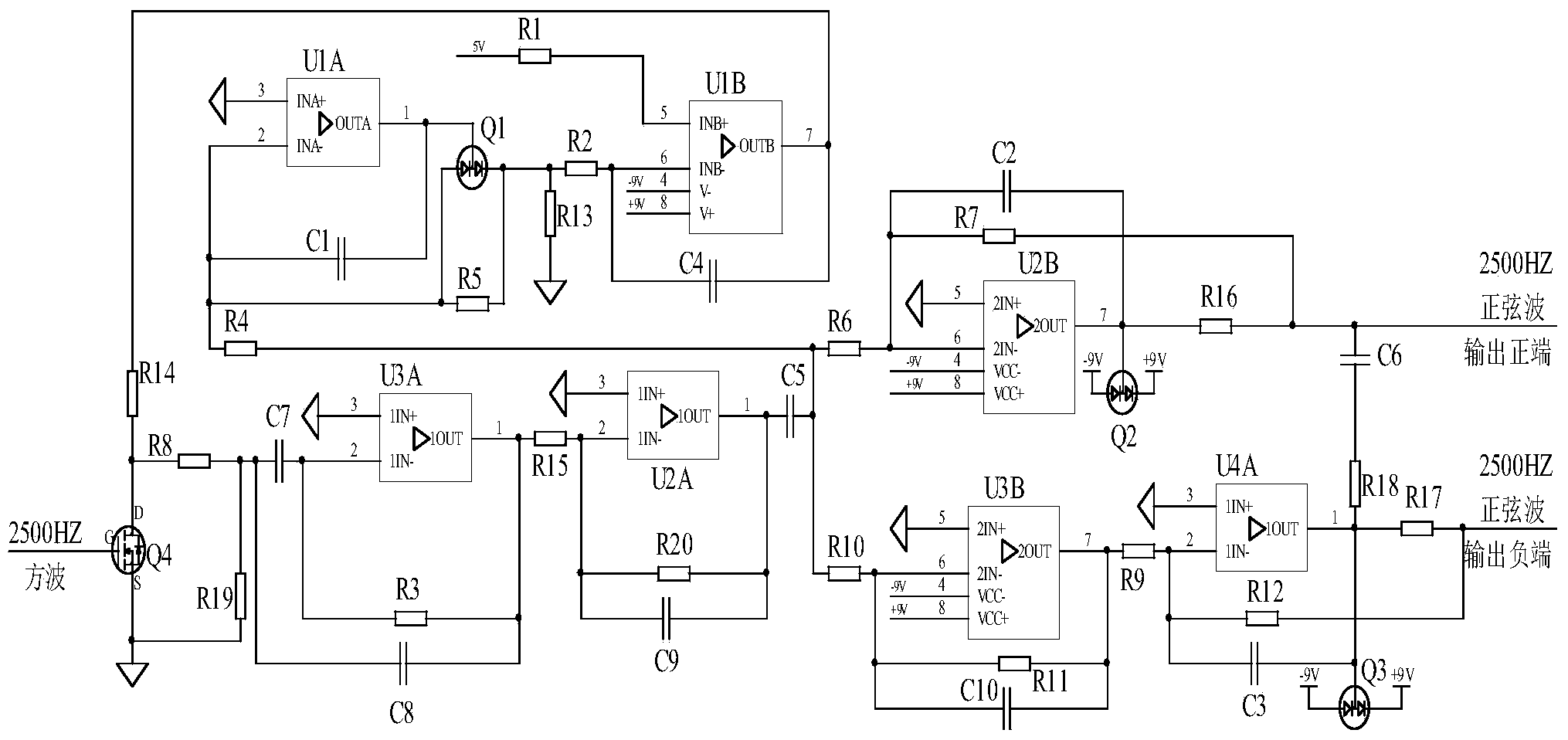

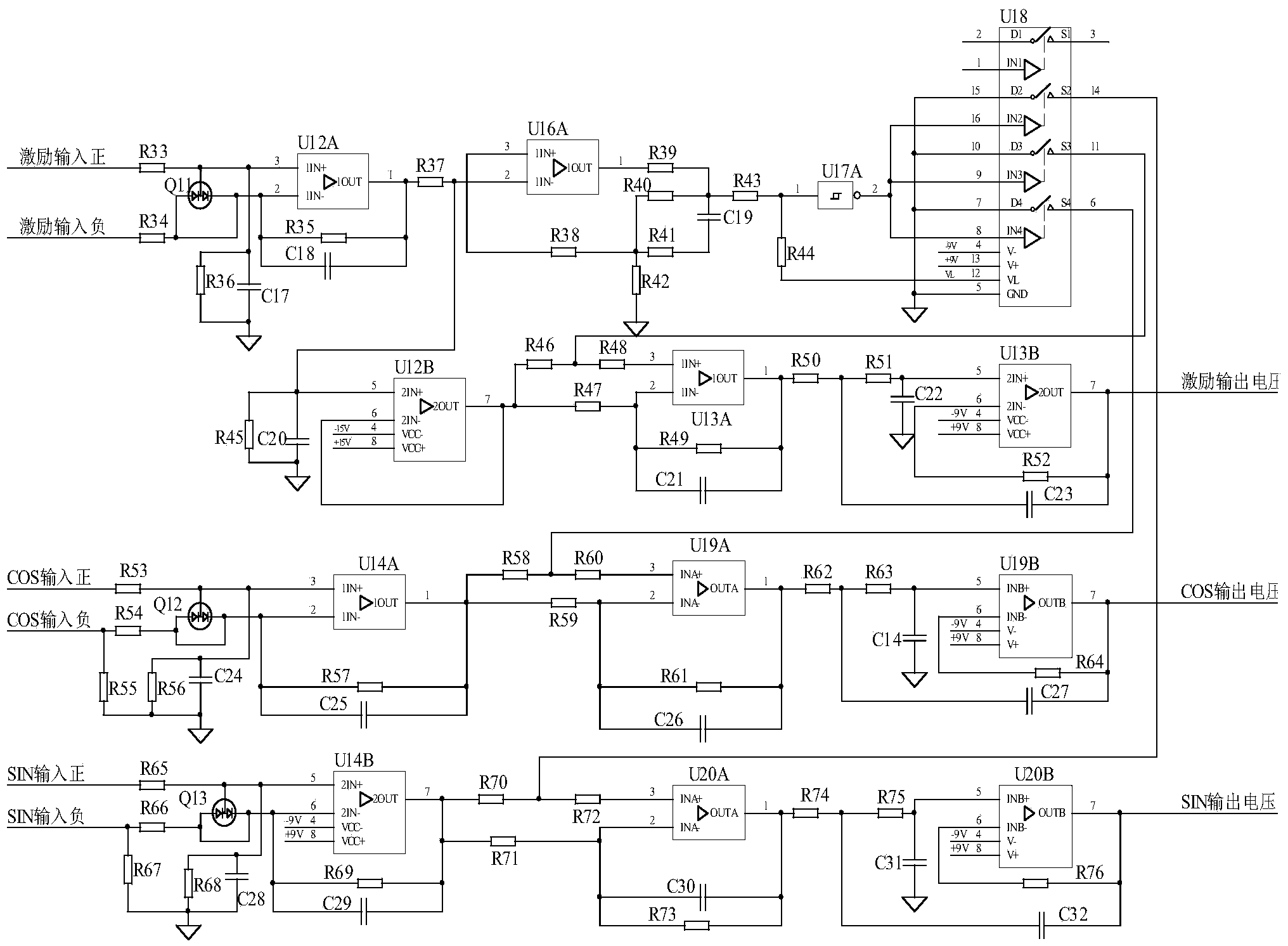

[0015] refer to figure 1 . Engine oil needle position sensor detection circuit includes 2500HZ square wave to sine wave circuit, oil needle position excitation amplifier circuit, oil needle position excitation output unit, half-wave control unit, and oil needle position excitation, sine SIN, cosine COS three-way channel Sine wave amplifier circuit, sine wave to half wave unit, half wave to DC voltage unit. The 2500HZ square wave generated by the engine electronic controller CPU is sent to the 2500HZ square wave to sine wave circuit, and the square wave to sine wave circuit converts the 2500HZ square wave signal output by the engine controller CPU into two standard 2500HZ sine waves with the same frequency The signal is sent to the excitation terminal of the oil needle position sensor. The sine SIN and cosine COS signals output by the oil needle position sensor enter the oil needle position detection circuit to form three similar acquisition channels for the oil needle positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com