Microbial fuel cell, cathode, cathode catalyst and preparation methods thereof

A cathode catalyst and fuel cell technology, applied in biochemical fuel cells, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of high price, restricting the development and application of MFC, and limited sources, and achieve low cost and oxygen catalytic reduction The effect of excellent performance and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

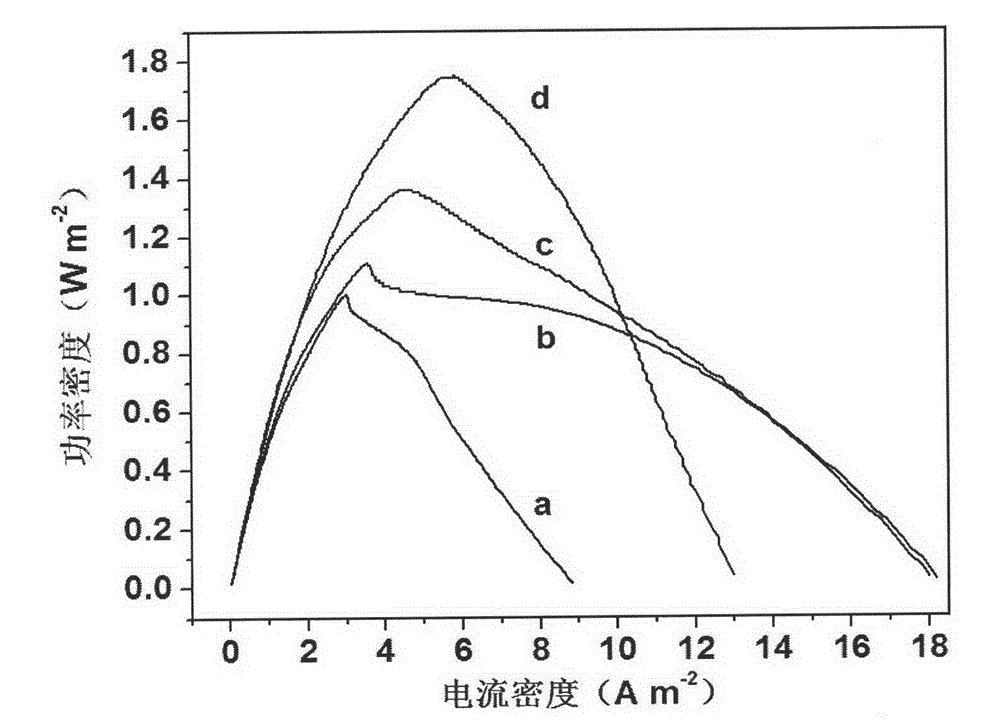

Embodiment 1

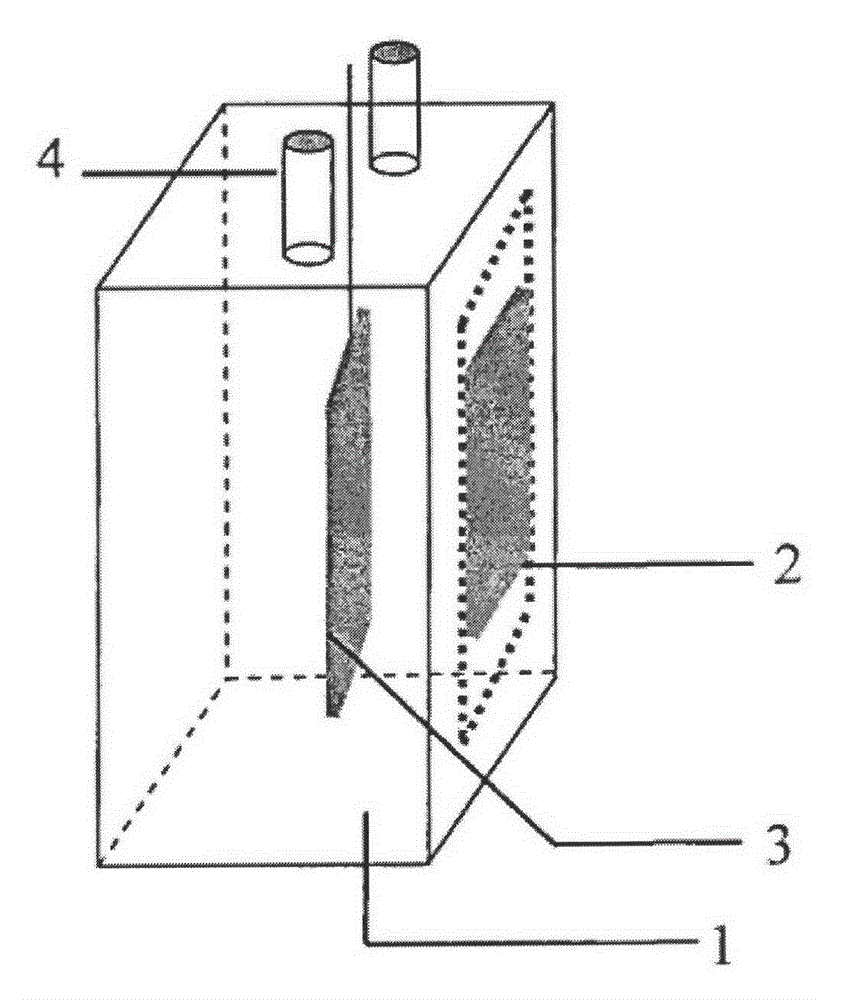

[0028] The preparation method of MFC of the present invention mainly comprises following flow process:

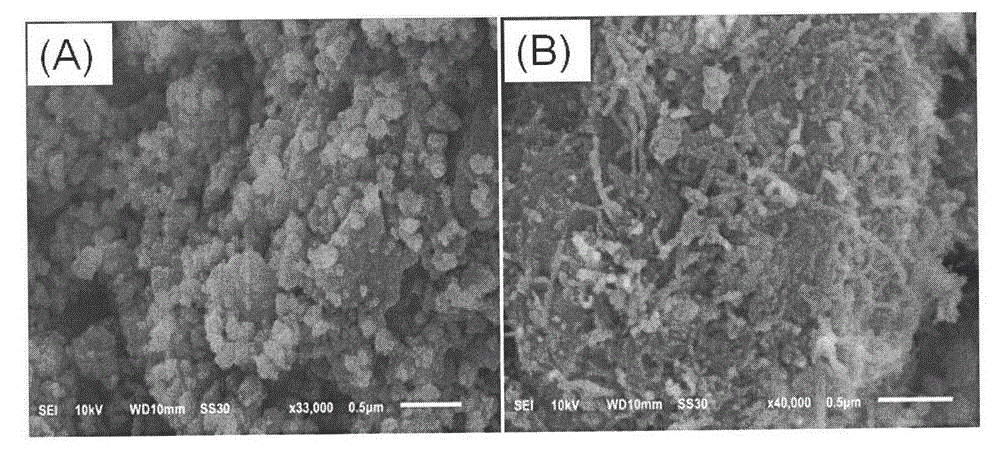

[0029] The first step is to prepare the cathode catalyst: first, at room temperature, get 50 milliliters of 0.04 mol / liter potassium permanganate solution, adjust its pH value to 12 with 0.1 mol / liter sodium hydroxide solution, and then add the permanganese Add 100 milliliters of 0.03 mol / liter manganese acetate solution to potassium acid potassium solution, stir with a glass rod while adding, react to form a tan precipitate, wash the precipitate with deionized water, filter the precipitate and place it at 60 degrees Celsius Dry overnight to obtain amorphous manganese dioxide; then, weigh 0.348 grams of amorphous manganese dioxide and 0.476 grams of cobalt chloride 6 hydrate, mix the two in 20 milliliters of deionized water, and ultrasonically treat them for 30 minutes to make them fully Mix well, and at room temperature, while stirring with strong magnetic force, excessive...

Embodiment 2

[0038] The preparation method of MFC of the present invention mainly comprises following flow process:

[0039] The first step is to prepare the cathode catalyst: first, at room temperature, get 50 milliliters of 0.04 mol / liter potassium permanganate solution, adjust its pH value to 12 with 0.1 mol / liter sodium hydroxide solution, and then add the permanganese Add 100 milliliters of 0.03 mol / liter manganese acetate solution to potassium acid potassium solution, stir with a glass rod while adding, react to form a tan precipitate, wash the precipitate with deionized water, filter the precipitate and place it at 60 degrees Celsius Dry overnight to obtain amorphous manganese dioxide; then, weigh 0.348 grams of amorphous manganese dioxide, 0.476 grams of cobalt chloride 6 hydrate and 0.012 grams of carbon nanotubes, mix the three in 20 milliliters of deionized water, and ultrasonicate for 30 Minutes, the two are fully mixed evenly, at room temperature, while strong magnetic stirrin...

Embodiment 3

[0048] The preparation method of MFC of the present invention mainly comprises following flow process:

[0049] The first step is to prepare the cathode catalyst: first, at room temperature, get 50 milliliters of 0.04 mol / liter potassium permanganate solution, adjust its pH value to 12 with 0.1 mol / liter sodium hydroxide solution, and then add the permanganese Add 100 milliliters of 0.03 mol / liter manganese acetate solution to potassium acid potassium solution, stir with a glass rod while adding, react to form a tan precipitate, wash the precipitate with deionized water, filter the precipitate and place it at 60 degrees Celsius Dry overnight to obtain amorphous manganese dioxide; then, weigh 0.348 gram of amorphous manganese dioxide, 0.476 gram of cobalt chloride 6 hydrate and 0.155 gram of carbon nanotubes, mix the three in 20 milliliters of deionized water, and perform ultrasonic treatment for 30 Minutes, the two are fully mixed evenly, at room temperature, while strong magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com