Automatic test method for set top box mainboard

An automatic test, set-top box technology, applied in the direction of TV, electrical components, image communication, etc., can solve the problems of low factory pass rate of set-top box motherboard, low remote control compatibility, long test process, etc. The effect of using the remote control, strong compatibility and short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

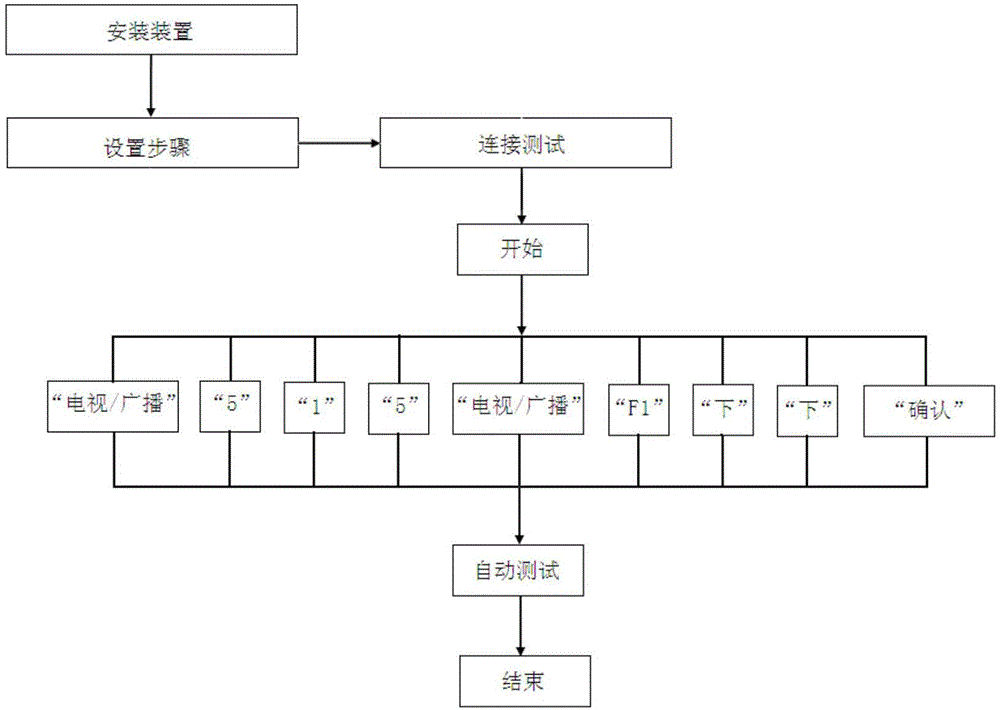

[0014] The set-top box motherboard automatic testing method that the present embodiment involves specifically comprises the following process steps:

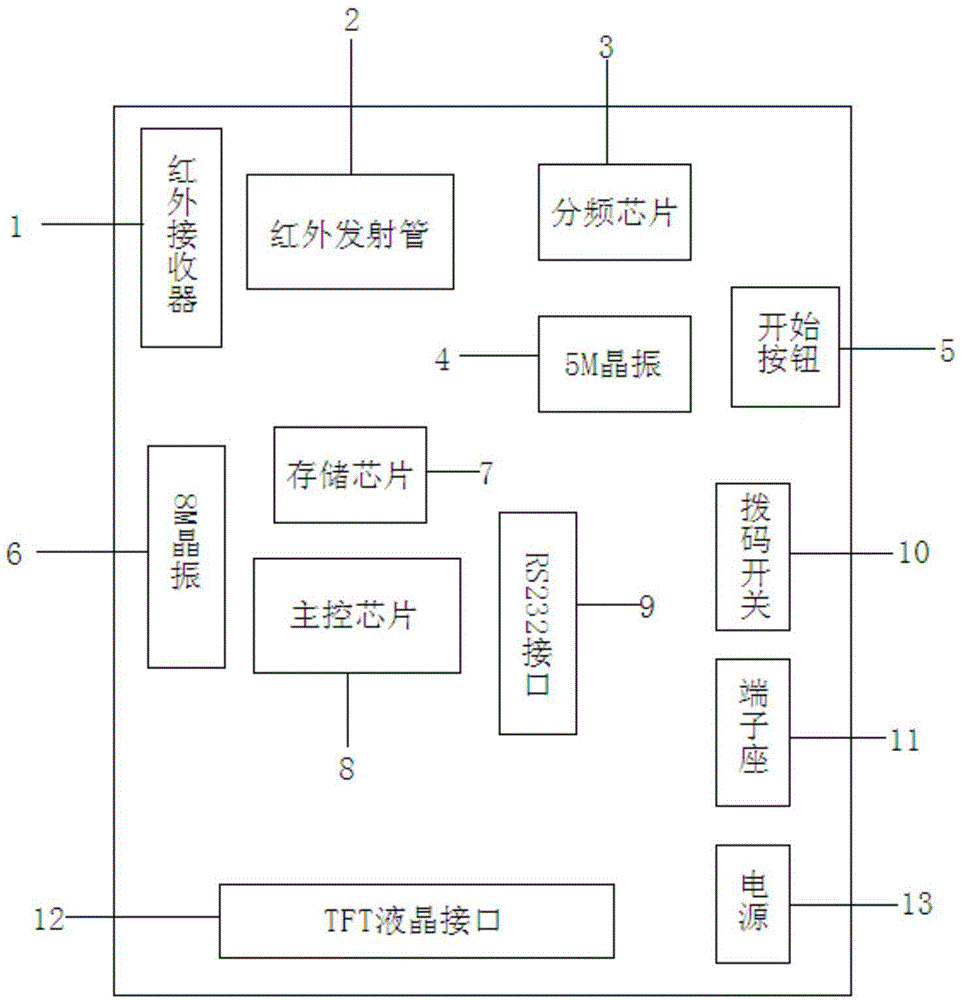

[0015] (1) Installation device: Infrared receiver 1, infrared emission tube 2, frequency division chip 3, 5M crystal oscillator 4, start button 5, 8M crystal oscillator 6, memory chip 7, main control chip 8, RS232 interface 9, dial switch 10. Terminal block 11, TFT (thin film field effect transistor) liquid crystal interface 12 and power supply 13 are assembled according to the electrical structure principle and connection relationship, and the chip program is written into the main control chip 8 through the RS232 interface by an external computer;

[0016] (2) Setting steps: turn the dial switch 10 to the setting mode state and turn on the power supply 13 to supply power, carry out the test step preset according to the general test standard of the set-top box main board, press the "TV / radio" key, "5" in sequence with the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com