Mouth rinse composition

A technology of composition and mouthwash, applied in oral care, medical science, dentistry, etc., can solve problems such as increased cost, inability to effectively eliminate odor, damaged gums or crowns, etc., to achieve odor elimination, low sensitivity, The effect of preventing bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

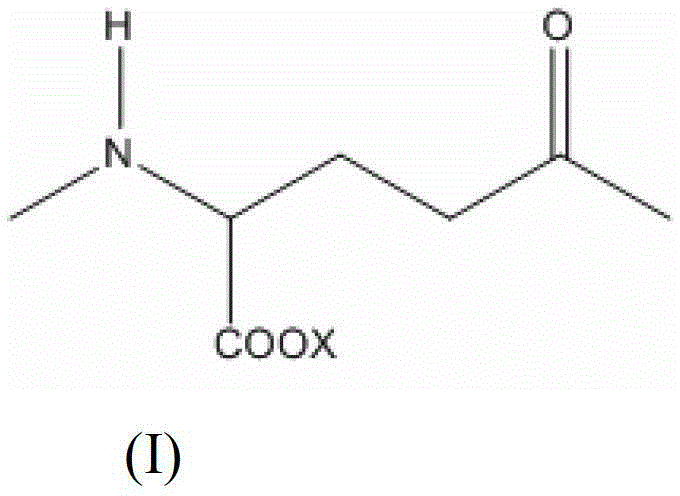

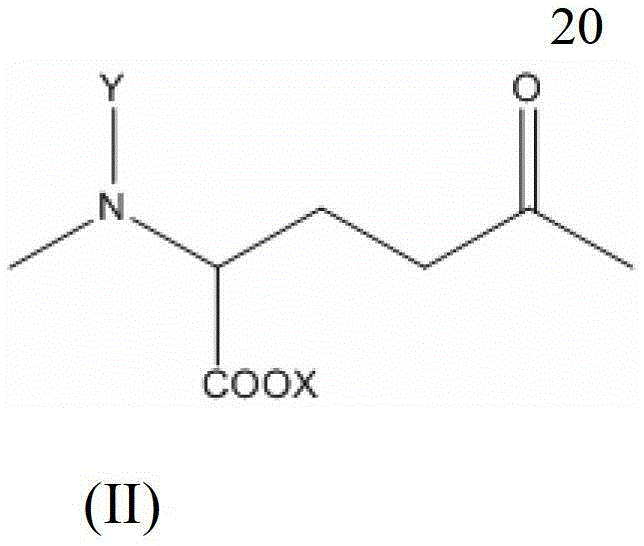

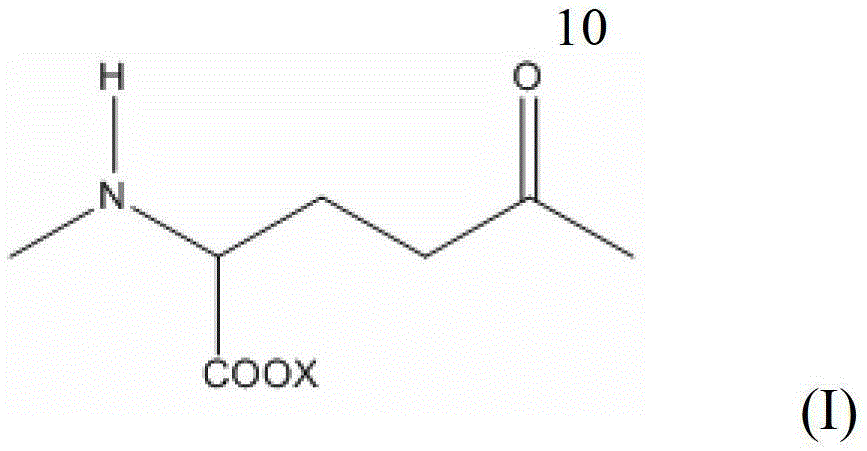

Method used

Image

Examples

Embodiment 1

[0046] Take 10.0 grams of polyglutamic acid (Polyglutamic acid, molecular weight about 2,000,000, Vedan, Taiwan) into a 250ml single-necked bottle, add 90ml of pure water to dissolve it, and prepare a polyglutamic acid aqueous solution. Add 4 g of 12.65 wt% sodium hypochlorite aqueous solution to form a mixed solution. The mixture was stirred continuously at room temperature for 30 minutes to react polyglutamic acid with sodium hypochlorite. The reacted mixed solution was placed in a separatory funnel, polymer 1 was precipitated with isopropanol, and after polymer 1 was separated from the separatory funnel, it was placed in a vacuum oven for drying. The dried product is a white to pale yellow powder, which can be completely dissolved in water. The dried polymer 1 was titrated with sodium thiosulfate to finally obtain the weight percentage of the N-Cl haloamine functional group in the modified polyglutamic acid.

Embodiment 2~6

[0048] The embodiment is as described in Example 1, but the sodium hypochlorite aqueous solution is added into the polyglutamic acid aqueous solution with the weight of 12, 20, 28, 36 and 40 g, respectively. The mixture was stirred continuously at room temperature for 30 minutes to react polyglutamic acid with sodium hypochlorite. Put the reacted mixed solution in a separatory funnel respectively, precipitate polymers 2-6 with isopropanol, separate polymers 2-6 from the separatory funnel, and place them in a vacuum oven for drying. The dried product is a white to pale yellow powder, which can be completely dissolved in water. The dried polymers 2-6 were respectively titrated with sodium thiosulfate, and finally the weight percentage of the N-Cl haloamine functional group in the modified polyglutamic acid was obtained.

Embodiment 7~8

[0050] Embodiment and proportioning are as described in Example 1, but the time of stirring the mixed solution at room temperature is extended to 90 and 180 minutes respectively, after the reaction time is reached, the mixed solution after the reaction is similarly placed in a separatory funnel, Polymers 7 and 8 were precipitated with isopropanol, and polymers 7 and 8 were separated out of a separatory funnel and placed in a vacuum oven for drying. The dried product is a white to pale yellow powder, which can be completely dissolved in water. The dried polymers 7 and 8 were respectively titrated with sodium thiosulfate to finally obtain the weight percentage of the N-Cl haloamine functional group in the modified polyglutamic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com