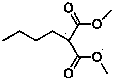

Method for preparing dimethyl n-butyl malonate

A technology of n-butyl dimethyl malonate and dimethyl malonate, which is applied in the field of n-butyl dimethyl malonate to prepare dimethyl n-butyl malonate, can solve the problem of high cost, Difficult product separation, complex preparation methods and other problems, to achieve the effect of low cost, simple operation, and easy to achieve reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

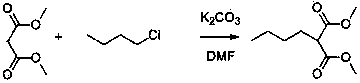

Method used

Image

Examples

Embodiment 1

[0021] 264.22g (227.78ml, 2.0mol) dimethyl malonate, 231.43g (260.03ml, 2.5mol) chlorobutane, 131.29g (0.95mol) anhydrous potassium carbonate powder, 438.55g (464.4ml, 6.0 mol) DMF, added to a three-necked flask, equipped with a condensing reflux device, a thermometer, heated and stirred, and the reaction temperature was 110-120°C. After reacting for 2 hours, in order to maintain the concentration of n-chlorobutane in the reaction, 185.14g (208.02 ml, 2.0mol) of n-chlorobutane was added to the reaction solution. The reflux reaction was continued for 3 hours, and 2.58 g (0.008 mol) of tetrabutylammonium bromide TBAB was added slowly, and the addition was completed in half an hour.

[0022] After adding the phase transfer catalyst, continue the reaction and track the reaction with GC, when the conversion rate of dimethyl malonate can reach 90% (GC analysis after about 6 hours). The reaction mixture was distilled off chlorobutane at 110-120°C, cooled, filtered, and the filtrate ...

Embodiment 2

[0025] 264.22g (227.78ml, 2.0mol) dimethyl malonate, 185.14g (208.02ml, 2.0mol) chlorobutane, 165.84g (1.20mol) anhydrous potassium carbonate powder, 511.64g (541.3ml, 7.0 mol) DMF, added to a three-necked flask, equipped with a condensing reflux device, a thermometer, heated and stirred, and the reaction temperature was 110-120°C. After reacting for 2 hours, in order to maintain the concentration of n-chlorobutane in the reaction, 231.43g (260.03ml, 2.5mol) of n-chlorobutane was added to the reaction solution. The reflux reaction was continued for 3 hours, and 2.58 g (0.008 mol) of tetrabutylammonium bromide TBAB was added slowly, and the addition was completed in half an hour.

[0026] After adding the phase transfer catalyst, continue the reaction and track the reaction with GC, when the conversion rate of dimethyl malonate can reach 90% (GC analysis after about 6 hours). The reaction mixture was distilled off chlorobutane at 110-120°C, cooled, filtered, and the filtrate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com