Method for micro-suspension polymerization preparation of sub-micron polyurethane-modified polyacrylate copolymerized latex

A technology of polyurethane modification and polyacrylate, which is applied in the direction of grafting polymer adhesives, adhesives, adhesive types, etc., can solve the problems of harmful co-emulsifiers and low solid content of the final product, and achieve high solid content , Facilitate ultrasonic homogenization, improve the effect of mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

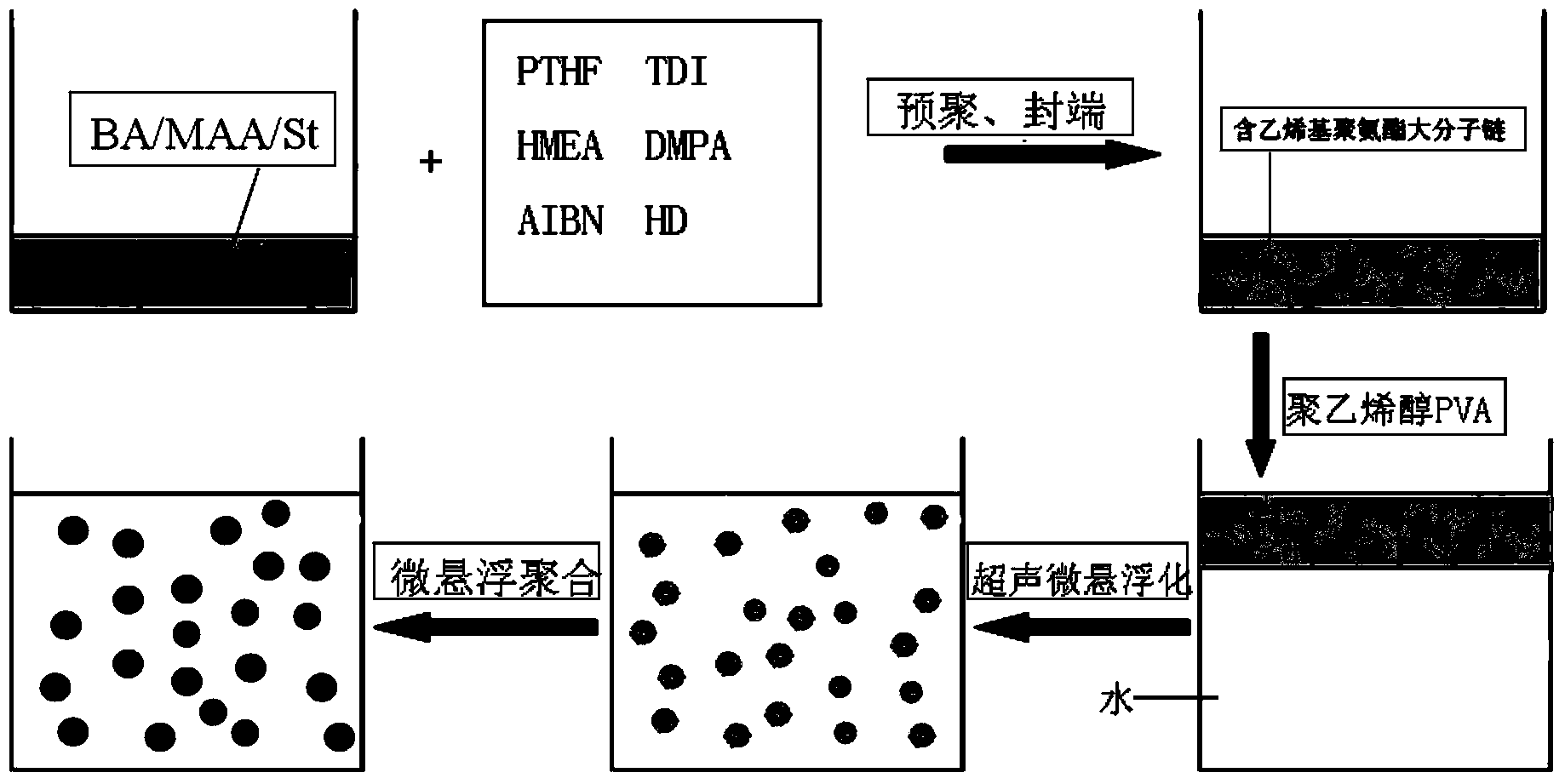

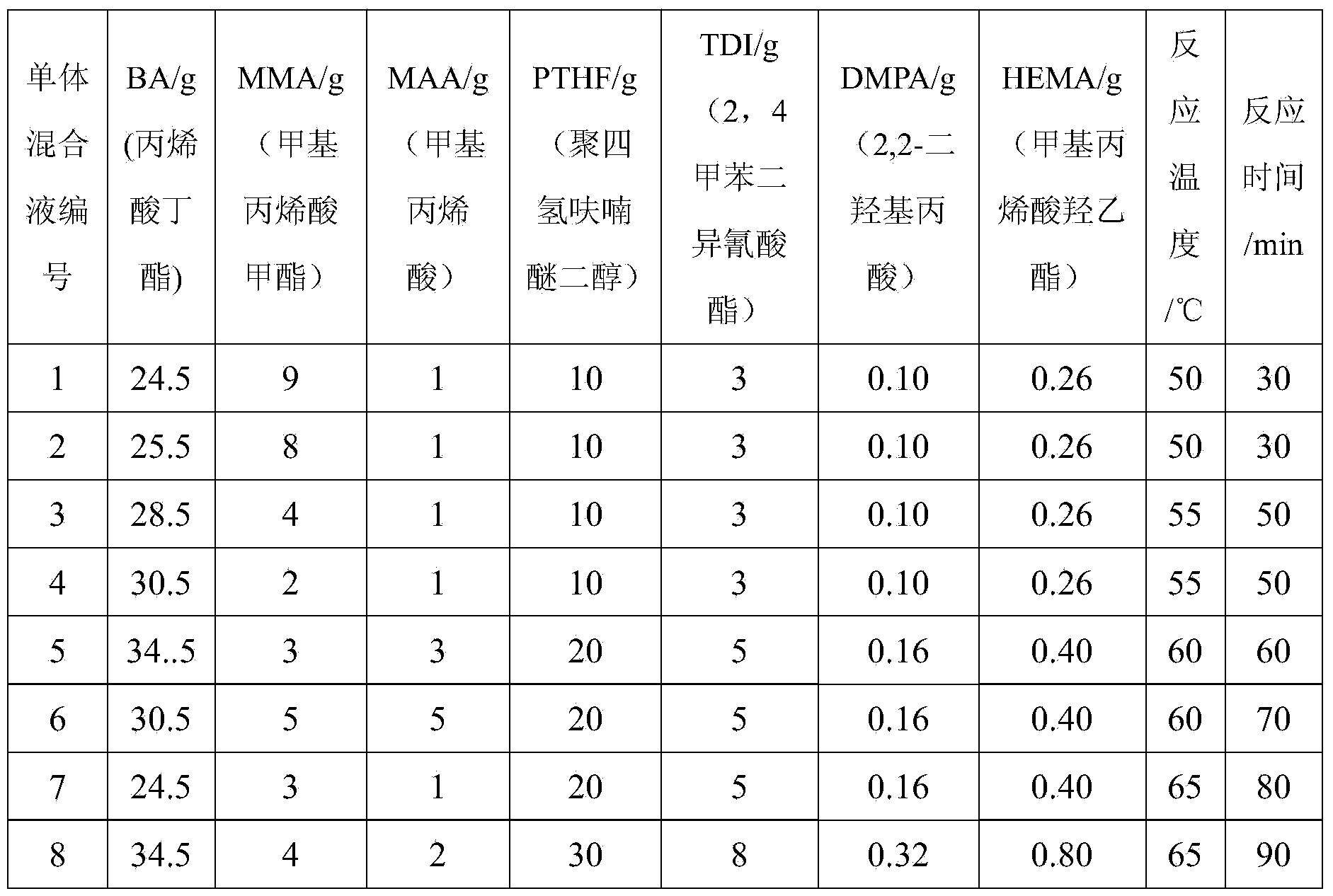

[0037] According to the feed ratio shown in Table 1, monomer mixtures with different monomer ratios were prepared. Proceed as follows:

[0038] Add the isocyanate monomer and polyol to an appropriate amount of acrylate monomer containing hexadecane as an emulsifier to obtain a monomer mixture, add the catalyst dibutyllithium dilaurate, heat up to 60°C for prepolymerization for 30 minutes, add 2,2 dihydroxypropionic acid was subjected to chain extension reaction for 45 minutes, and finally an end-capping agent was added for end-capping to obtain an oily monomer mixture.

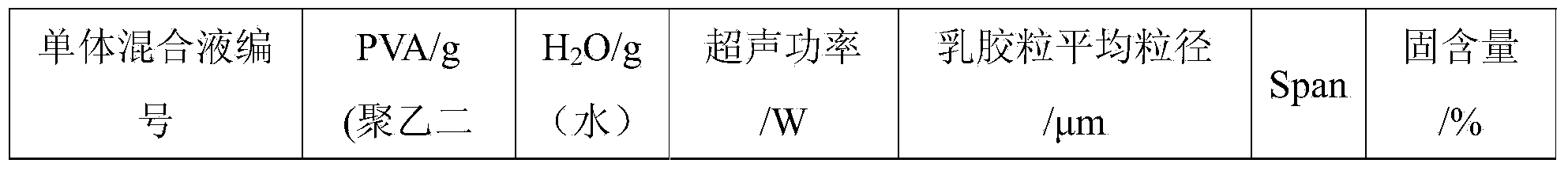

[0039] Carry out fine emulsification and polymerization reaction according to the technological formula shown in table 2, step is as follows:

[0040] Add the initiator azobisisobutylcyanide (AIBN) into the oily monomer mixture, after it is completely dissolved, pour the monomer mixture into the aqueous solution of the dispersant polyvinyl alcohol PVA, and microsuspend it by ultrasonic to obtain a microsuspen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com