Ultra-low density polypropylene composite material capable of being used for 3D printing and preparation method thereof.

An ultra-low-density, 3D printing technology, which is applied in the preparation of composite materials and the field of ultra-low-density polypropylene composite materials, can solve the problems of limited use of printed objects, good mechanical properties of ABS, and easy brittle fracture, so as to reduce shrinkage. , improve performance, and speed up the effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

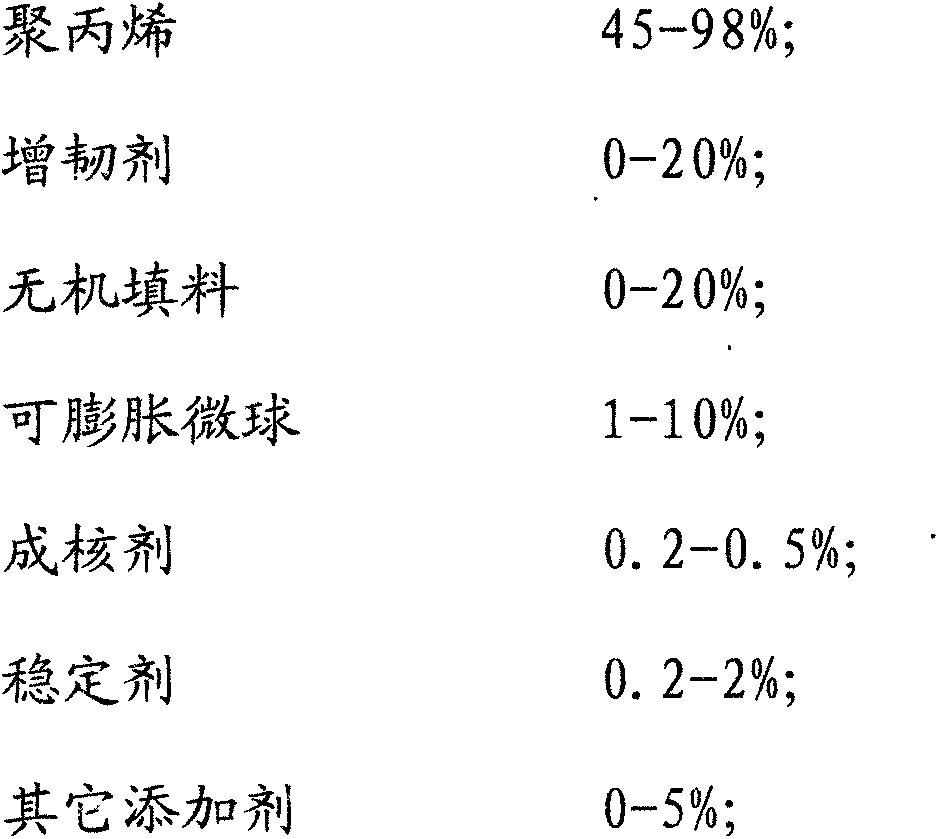

Method used

Image

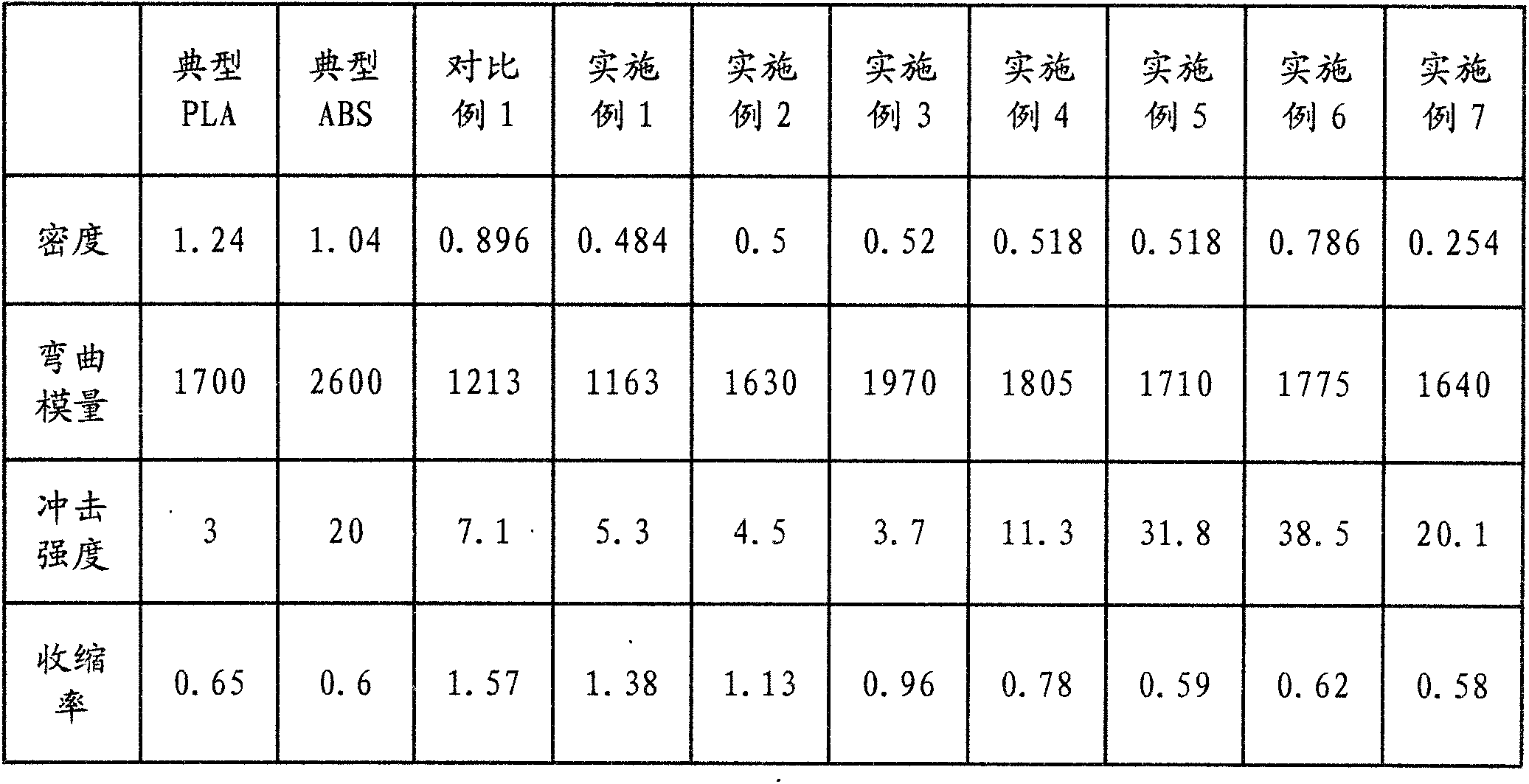

Examples

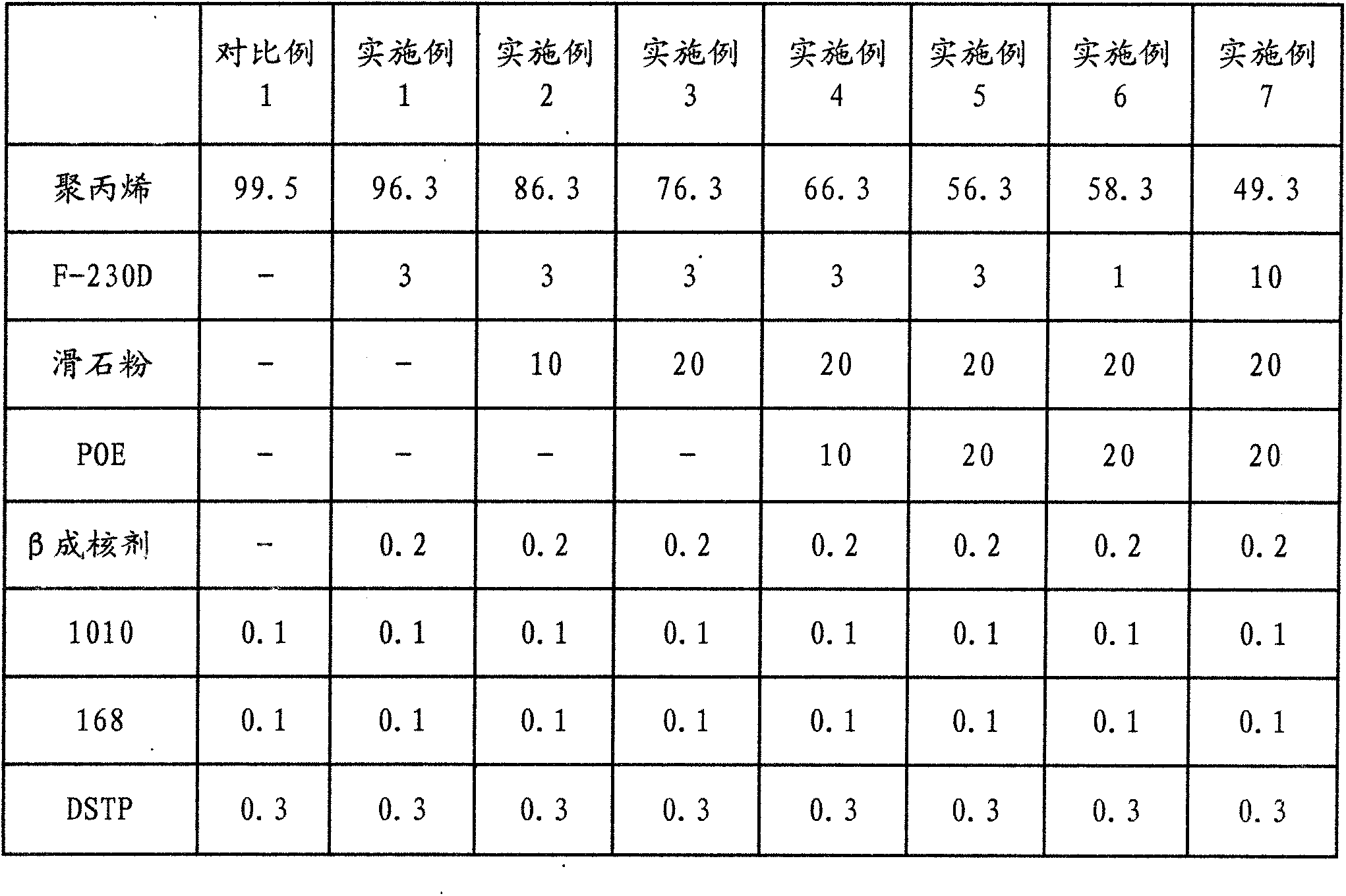

Embodiment 1

[0027] Weigh 96.3% of polypropylene, 3% of F-230D, 0.2% of TMB-5, 0.1% of Irganox1010, 0.1% of Igrafos 168, and 0.3% of Negonox DSTP by weight, and put the weighed materials into the high-speed Dry mix in the mixer for 5 minutes, then add to the twin-screw extruder to melt and extrude to granulate. The temperature of the head is 180°C, the rotational speed of the twin-screw extruder is set at 500 rpm, and the pellets are dried and injection-molded on an injection molding machine for sample preparation.

Embodiment 2

[0029] Weigh 86.3% of polypropylene, 10% of talcum powder, 3% of F-230D, 0.2% of TMB-5, 0.1% of Irganox 1010, 0.1% of Igrafos 168, and 0.3% of Negonox DSTP by weight percentage. Put the good material into the high-speed mixer and dry mix it for 5 minutes, then put it into the twin-screw extruder to melt and extrude to granulate. The fourth zone is 190°C, the temperature of the head is 180°C, the speed of the twin-screw extruder is set at 500 rpm, and the particles are dried and injection molded on the injection molding machine for sample preparation.

Embodiment 3

[0031] Weigh 76.3% of polypropylene, 20% of talcum powder, 3% of F-230D, 0.2% of TMB-5, 0.1% of Irganox 1010, 0.1% of Igrafos 168, and 0.3% of Negonox DSTP by weight percentage. Put the good material into the high-speed mixer and dry mix it for 5 minutes, then put it into the twin-screw extruder to melt and extrude to granulate. The fourth zone is 190°C, the temperature of the head is 180°C, the speed of the twin-screw extruder is set at 500 rpm, and the particles are dried and injection molded on the injection molding machine for sample preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com